Warp-knitted self-fastening hook face fabric and manufacturing method thereof

A warp knitting and fabric technology, applied in warp knitting, textiles, papermaking, fasteners, etc., can solve the problem of low bonding strength and hook strength, hard hook surface base fabric, unfavorable hook surface and rough surface multiple punctures and collusion and other problems, to achieve the effect of improving the bonding strength and collusion strength, the distribution density is large, and the barb penetration effect is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

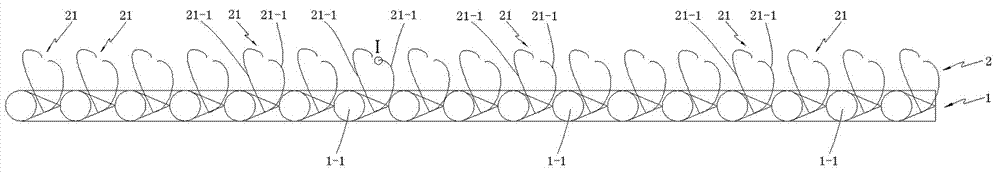

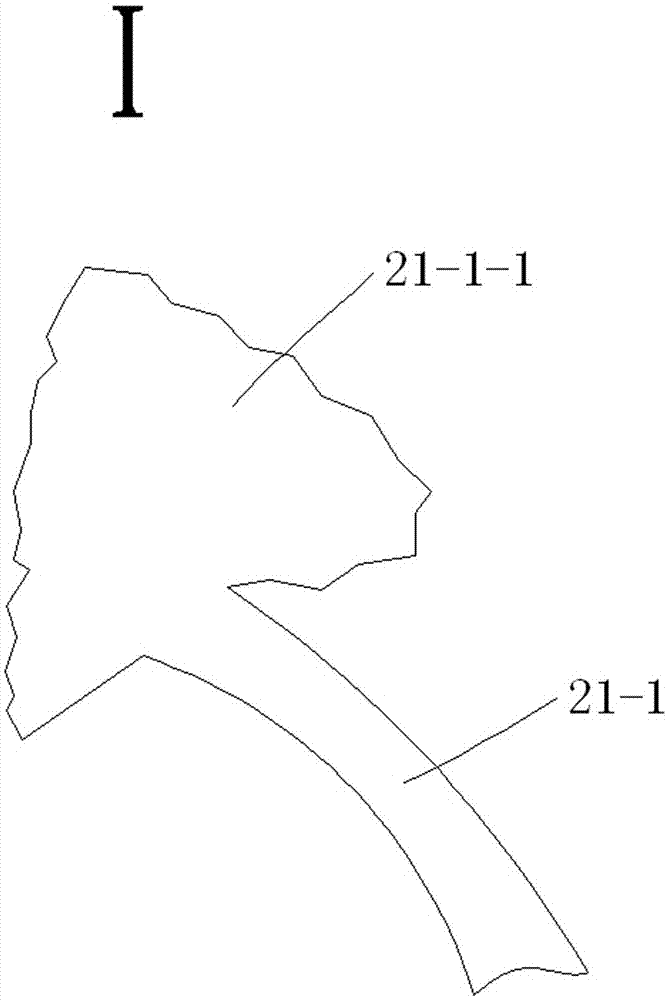

[0021] see figure 1 , 2 Shown is a kind of warp-knitted self-adhesive hook surface fabric, which comprises a base fabric 1 made of a warp-knitted mesh fabric woven by a Raschel warp knitting machine, and a plurality of fabrics on one surface of the base fabric 1. The loop layer 2 is composed of arched loops 21, each of which is broken into two oppositely arranged barbs 21-1, and the tip of each barb 21-1 is an irregular protrusion 21-1-1.

[0022] In the present invention, the base fabric 1 is preferably warp-knitted mesh fabric woven by polypropylene monofilament 1-1, and the protrusion 21-1-1 at the top of the barb 21-1 is in an irregular triangular shape.

[0023] In the present invention, the basis weight per unit area of the base fabric 1 is 40-45g / m 2 , the length of each barb 21-1 is between 1 and 2 mm.

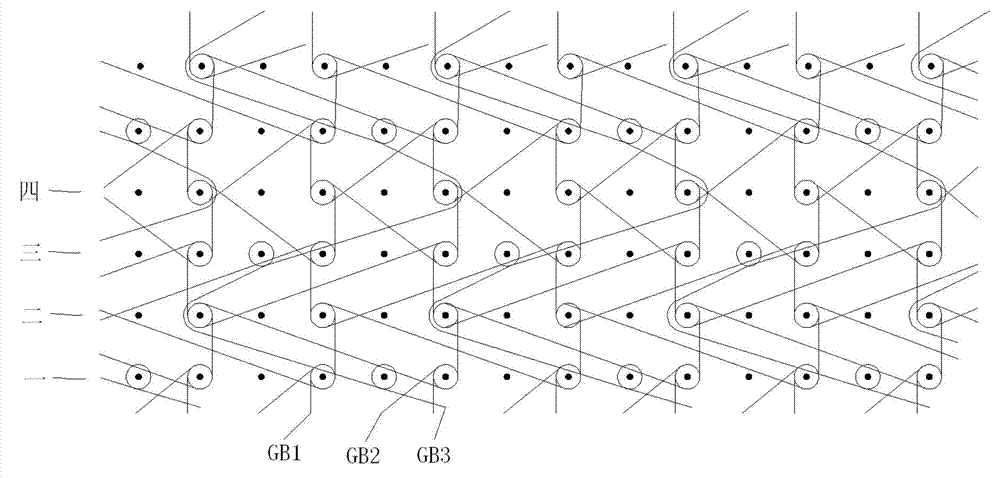

[0024] see image 3 Shown a kind of method of making described warp-knitted self-adhesive hook surface fabric, comprises the following steps:

[0025] Weaving ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com