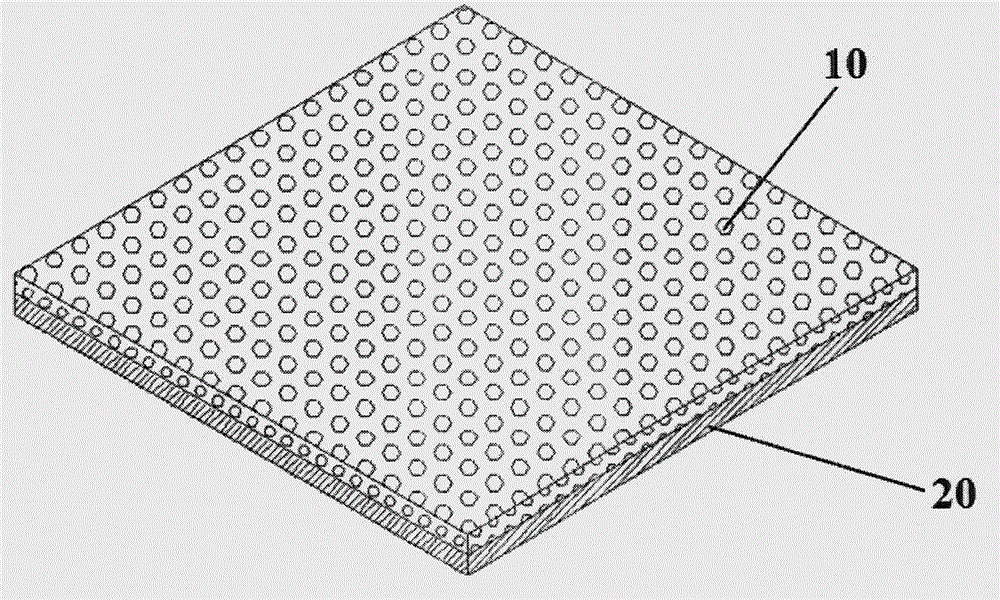

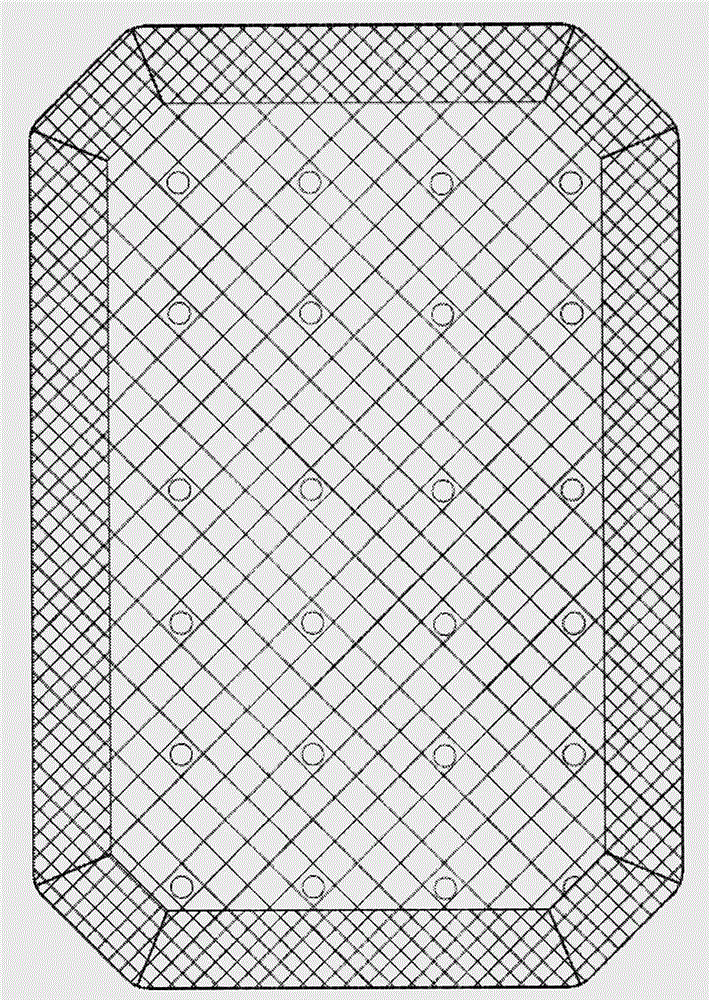

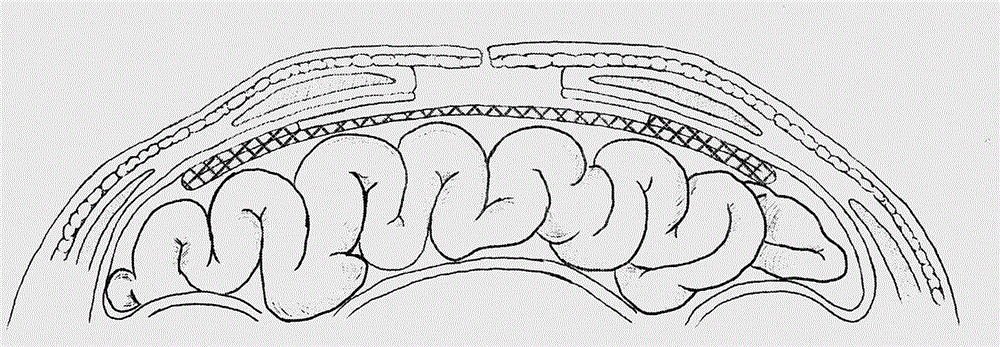

Abdominal hernia repair mesh specially used for open surgery

An open, hernia repair technology, applied in surgery, medical science, prosthesis, etc., can solve the problems of cumbersome preparation process, poor softness, and many chemical reactions, and achieve excellent ingrowth performance, good abdominal wall compliance, Mesh leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The manufacturing process of the abdominal wall hernia repair mesh dedicated to open surgery according to the present invention will be described in detail below with a specific embodiment. Described manufacturing process specifically comprises the following steps:

[0040] 1. Solution preparation

[0041] 1.1 Materials: PLCL pellets, acetone.

[0042] 1.2 Apparatus: 1000ml volumetric flask, 250ml measuring cylinder, 250ml Erlenmeyer flask.

[0043] 1.3 Environment: Class 100,000 clean workshop

[0044] 1.4 Equipment dry heat sterilization, 165 ℃, 2 hours. Rinse with acetone before use.

[0045] 1.5 Take the PLCL pellets, open it at room temperature, pour it into a 1000ml volumetric flask, add acetone to make the volume to 1000ml, cover the bottle tightly and place it at 40°C to dissolve for 48-72 hours, shake and shake during the period, and use it as a film-making PLCL solution for later use (PLCL concentration: 0.1 g / ml).

[0046] 1.6 Take 100ml of film-making ...

Embodiment 2

[0096] 1. Solution preparation

[0097] 1.1 Materials: PLCL, MPEG2000-PLLA6000, acetone.

[0098] 1.2 Apparatus: 1000ml volumetric flask, 250ml measuring cylinder, 250ml Erlenmeyer flask.

[0099] 1.3 Environment: Class 100,000 clean workshop

[0100] 1.4 Equipment dry heat sterilization, 165 ℃, 2 hours. Rinse with acetone before use.

[0101]1.5 Prepare 10, 30 or 50 grams of MPEG2000-PLLA6000, open it at room temperature, pour it into a 1000ml volumetric flask, add acetone, cap the bottle tightly and place it at 40°C to dissolve, then add 90, 70, 50 grams of PLCL and stir to dissolve completely , and add acetone to make it to 1000mL, and use it as a film-making mixed solution (the mass ratios of PLCL and MPEG2000-PLLA6000 are 9:1, 7:3, and 1:1, respectively).

[0102] 1.6 Take 100ml of film-making mixed solution and add it to a 250ml Erlenmeyer flask, then add 100ml of acetone, cap the bottle tightly and shake well, and use it as a coating mixed solution for later use.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com