Intelligent children toy assembled modular robot

A technology for children's toys and robots, which is applied in the field of intelligent children's toy assembly module robots, can solve the problems of inconvenient debugging and installation, large wiring harnesses, and the robot's flexibility cannot meet the requirements of market changes, and achieves the effect of convenient connection and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions in the embodiments of the present invention will be clearly and completely described below. Obviously, the described embodiments are only some of the embodiments of the present invention, but not all of them.

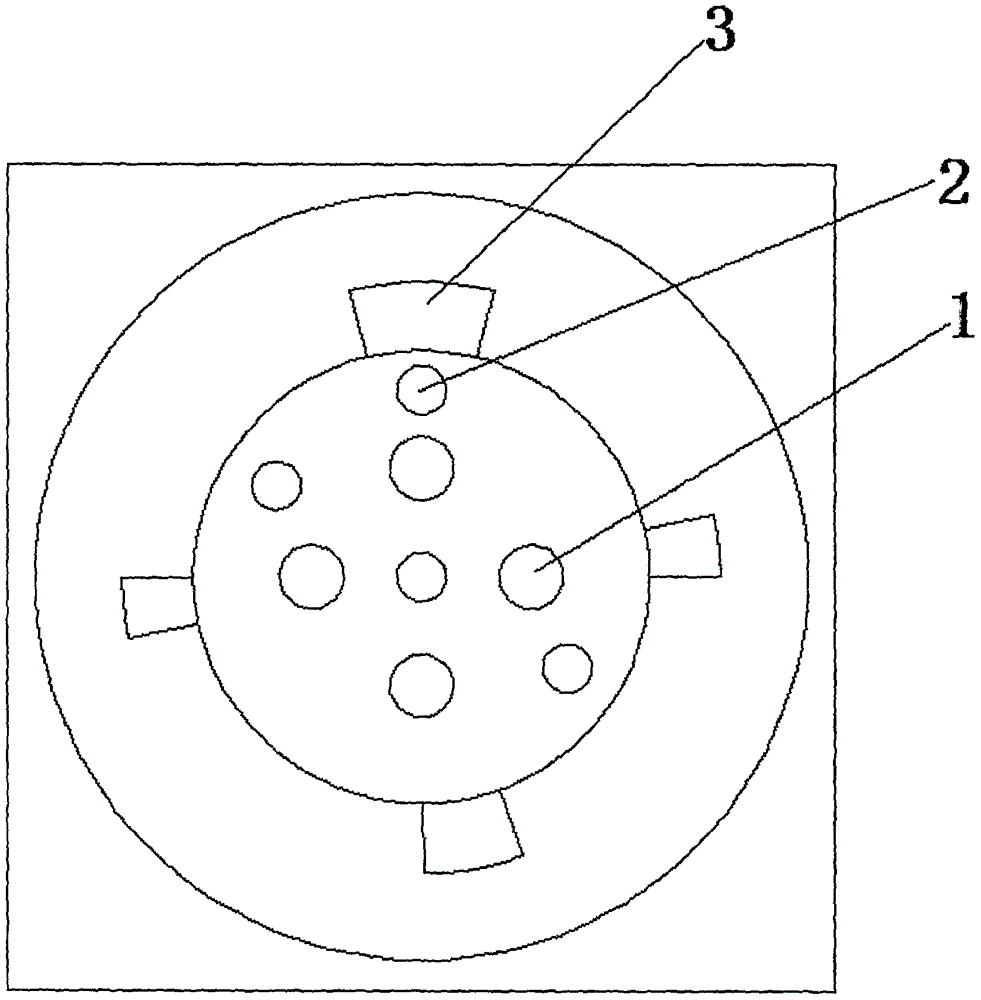

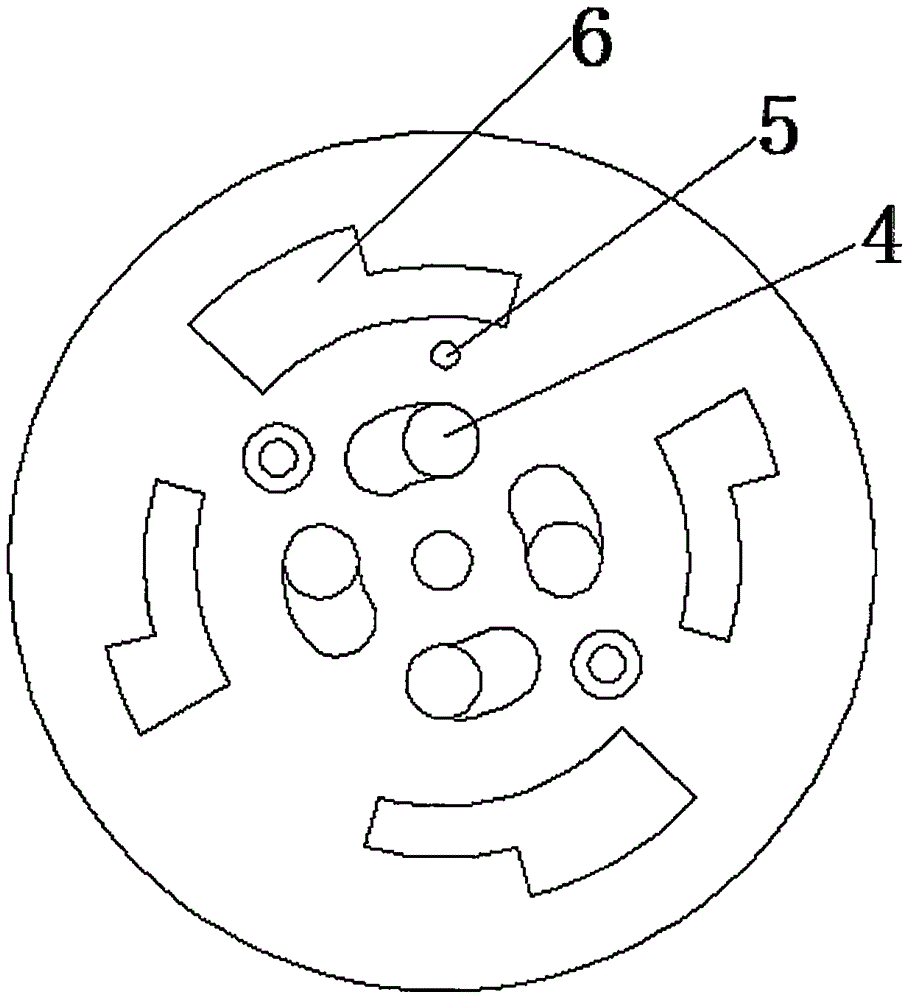

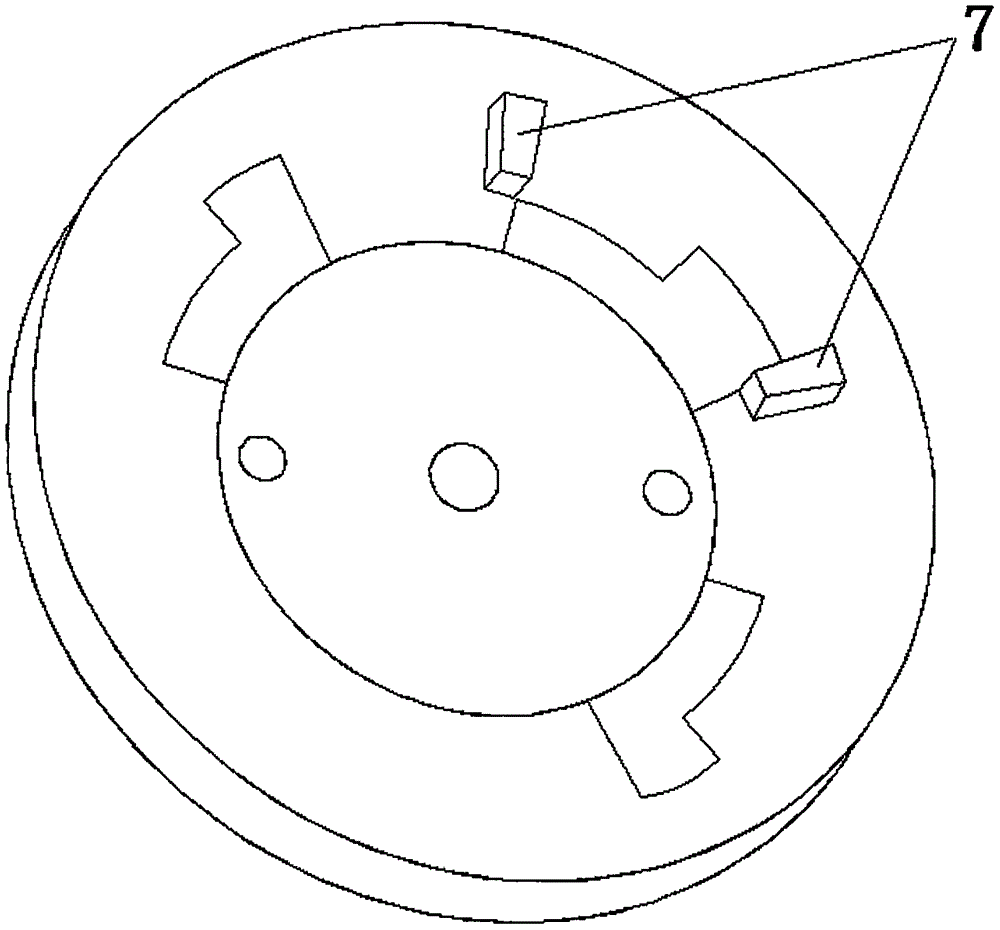

[0021] refer to Figure 1-4 , an intelligent children's toy assembly module robot, which is composed of multiple modules with different functions. Each module is equipped with a control board responsible for coordinating the communication between modules. The control board enables different modules to communicate with each other, and then Realize the interaction of information; because of the bus structure, the system can theoretically realize the coordinated work of 200 modules.

[0022] Every two modules are connected to each other through connecting surfaces. The connection surface is divided into three layers, which are respectively the first connection surface, the second connection surface and the third connection surface connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com