A laser marking focus calibration device and calibration method

A laser marking and calibration device technology, applied in the field of laser marking, can solve the problems of increasing operating time and increasing operating costs, and achieve the effects of saving operating costs, saving adjustment time, and easy standardized management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in conjunction with the accompanying drawings.

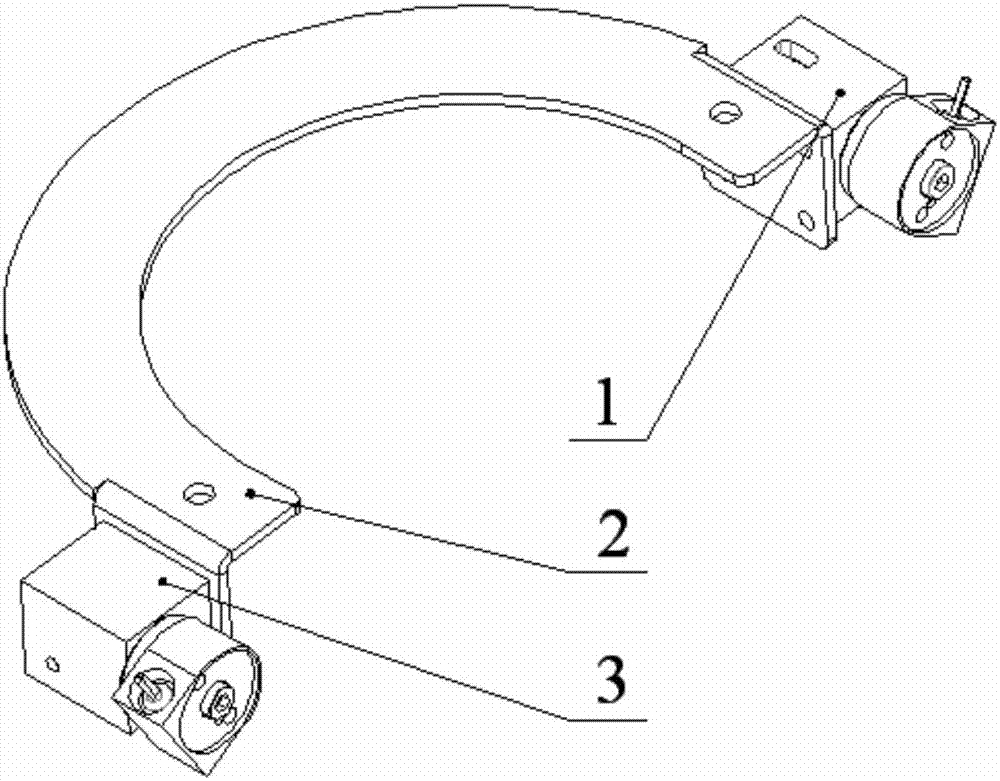

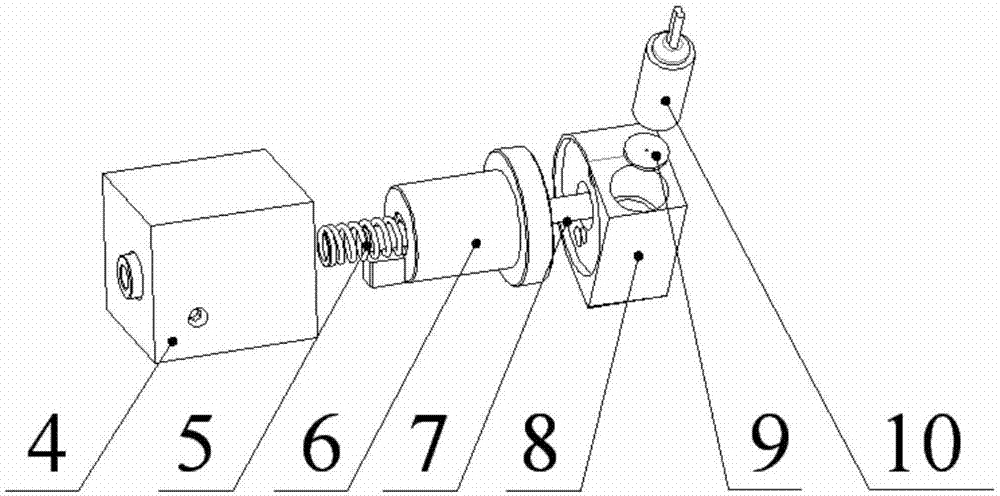

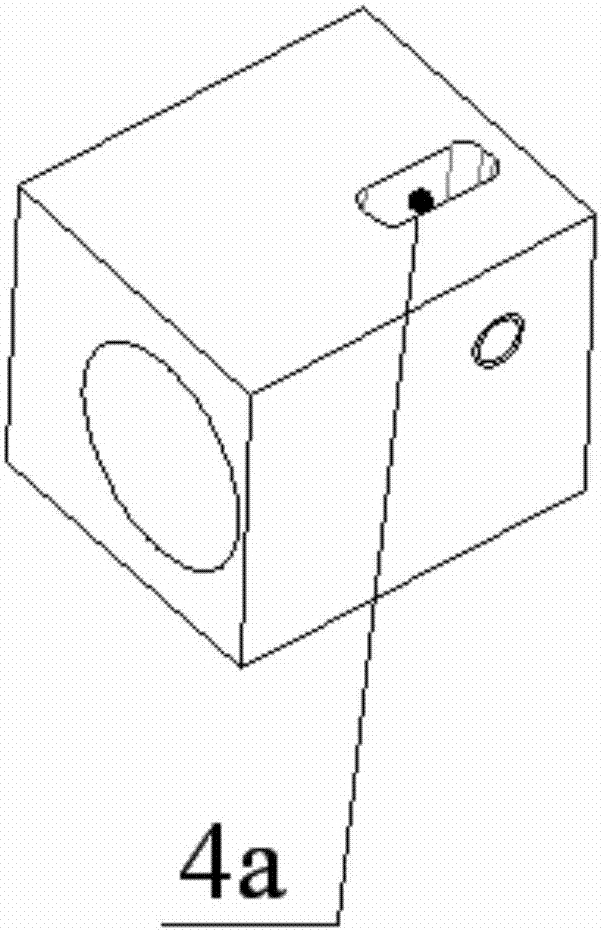

[0028] Such as figure 1 , figure 2 , Figure 5 As shown, the present invention includes a substrate 2 and two red light adjustment units (1, 3), which are characterized in that: the two red light adjustment units are symmetrically fixed on both sides of the substrate 2, and the red light adjustment unit Including fixed seat 4, adjusting shaft 6, adjusting bolt 7, red light tube base 8, red light tube 10, compression spring 5 and aperture diaphragm 9; The fixed seat 4 is connected, and the adjustment shaft 6 is slidingly matched with the fixed seat 4, and can slide along the axis direction of the adjustment bolt 7, and the red light tube seat 8 is slidingly fitted with the adjustment shaft 6, and can rotate around the axis of the adjustment shaft 6. The compression The spring 5 is set on the adjusting bolt 7, and is located between the adjusting shaft 6 and the fixed seat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com