Steering gear clamping device and clamping method suitable for steering gear testing platform

A test platform and clamping device technology, applied in workpiece clamping devices, workbenches, manufacturing tools, etc., can solve the problems of damage to the internal structure of the steering gear, inaccuracy, test data deviation, etc., and achieve the effect of reducing manual operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

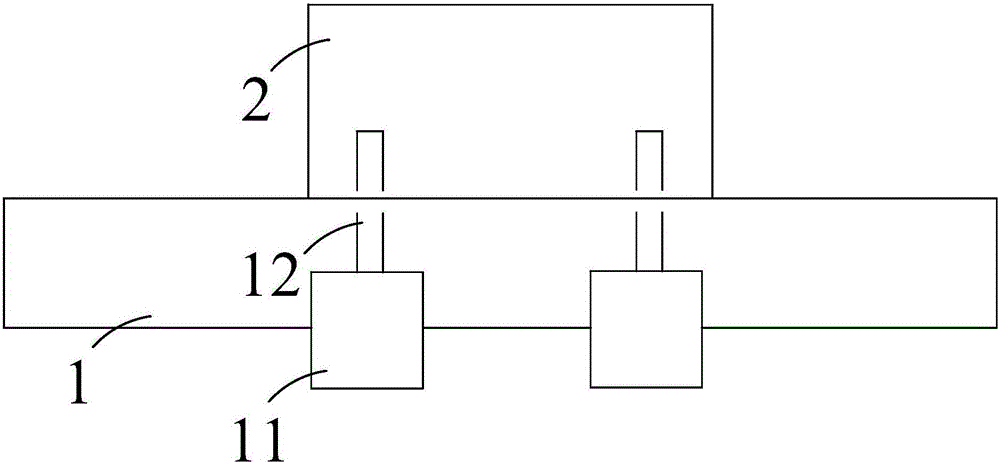

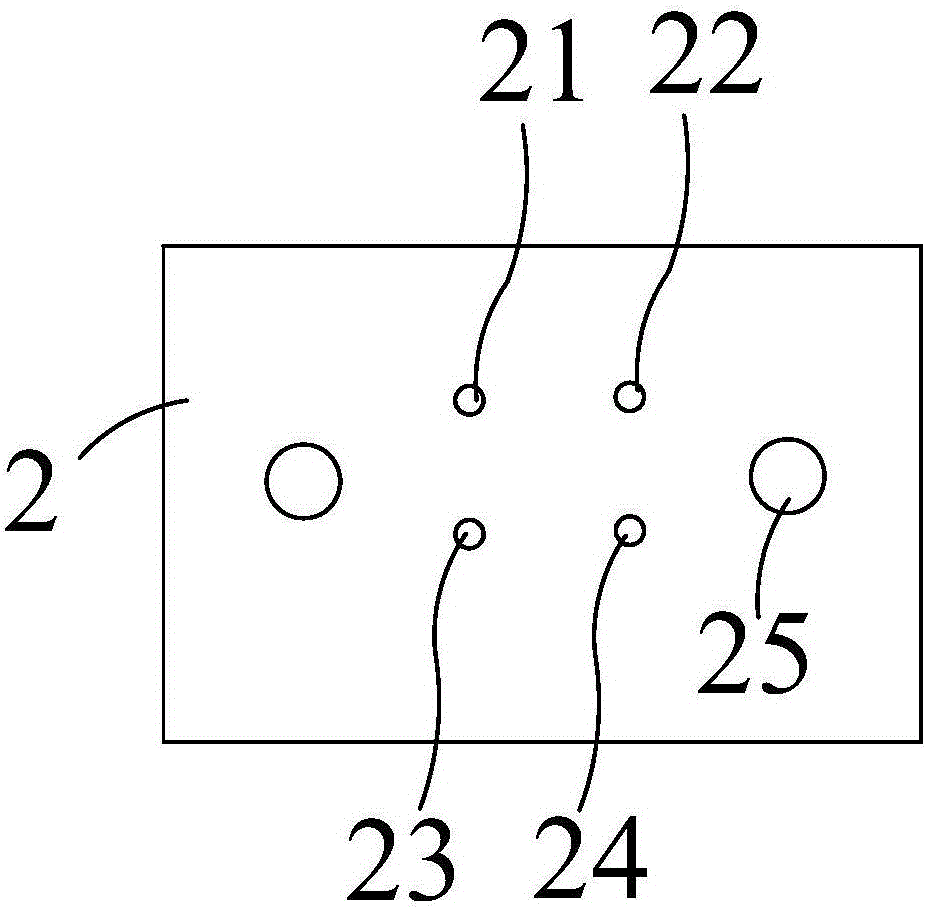

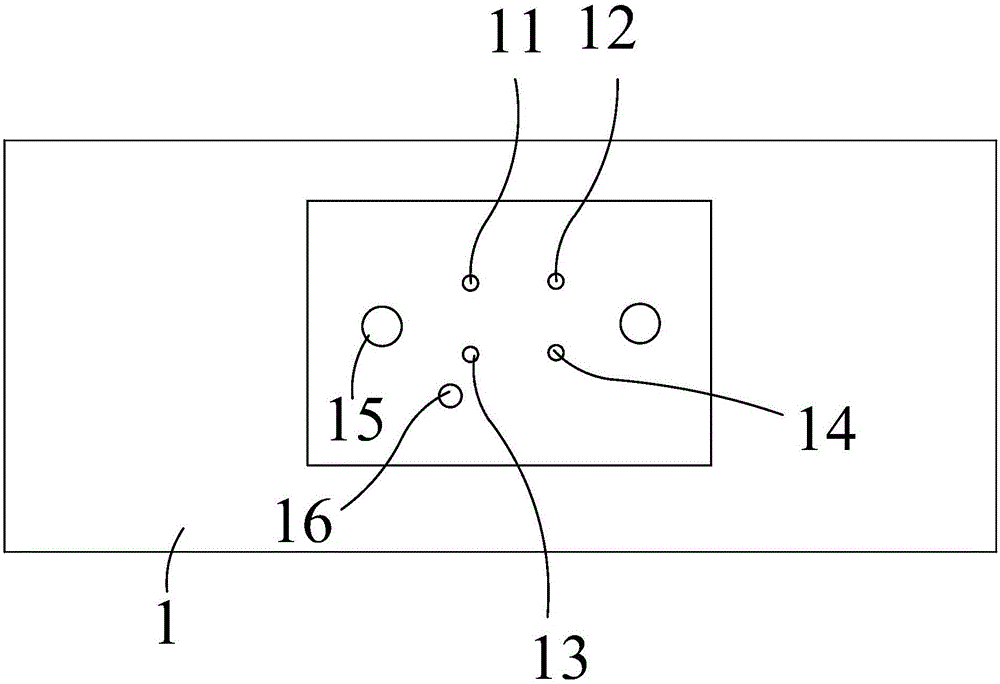

[0017] Embodiment 1, Figure 1 ~ Figure 3 A steering gear clamping device and clamping method suitable for the steering gear test platform are given. The steering gear clamping device suitable for the steering gear test platform is set in the steering gear test platform; it is mainly composed of a steering gear fixing platform 1 and a fixing device; the steering gear fixing platform 1 is a groove platform set with reference to the size of the steering gear, and the steering gear Corresponding to the P21, T22, A23 and B24 oil ports of the steering gear 2 on the fixed platform 1, there are corresponding P11, T12, A13 and B14 oil ports; corresponding to the screw hole 25 of the steering gear 2, there are corresponding fixing devices The fixing device includes a motor 11, and the output shaft 12 of the motor 11 is provided with bolts facing the screw holes. An oil collecting groove is arranged on the fixed platform of the steering gear, and an oil suction port 15 is arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com