Mechanical arm convenient to move

A technology of mechanical arms and driving mechanisms, applied in the directions of manipulators, claw arms, manufacturing tools, etc., can solve the problems of increased maintenance costs, breakage, and high production costs of manipulators, to ensure achievability, reduce shaking, and improve safety. and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

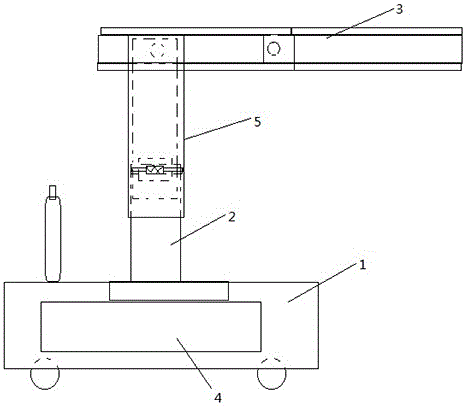

[0024] Such as figure 1 A mechanical arm that is easy to move is shown, including: a base 1, a column 2, a shaft joint 3 and a control device 4, wherein a storage box 5 is provided on one side of the column 2, and in the control device 4 It is equipped with a drive control module, an execution control module, a telescopic control module, an alarm control module and a central control module;

[0025] The relationship between the above components is as follows:

[0026] The column 2 is arranged on the base 1, the shaft joint 3 is connected with the column 2, and the shaft joints 3 are rotatably connected in pairs, and the connection between the two shaft joints 3 is provided with telescopic control mechanism, the telescopic control mechanism is provided with torsion springs and telescopic keys, the control device 4 is located in the base 1; the drive control module is connected to the base 1, and the execution control module is connected to the column 2 , the telescopic contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com