Rapid electric automobile molding realization method

A technology of electric vehicles and realization methods, applied in teaching models, electric digital data processing, instruments, etc., can solve problems such as inability to meet customer and market demand changes, limited processing parameters, and small auxiliary effects, etc., to achieve guaranteed reliability Achievement and accuracy, and the effect of shortening the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

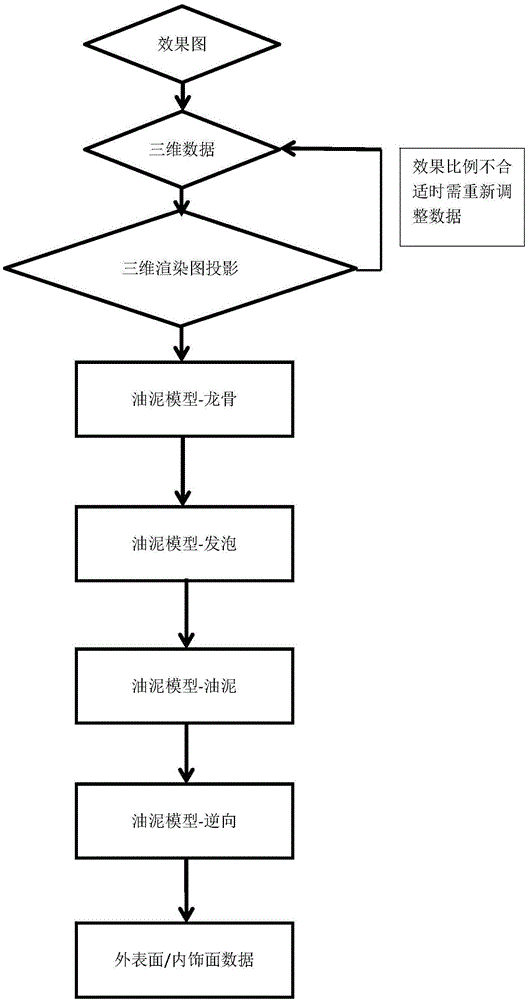

[0020] Such as figure 1 As shown, make a three-dimensional digital model (CAS surface) according to the selected renderings. After the three-dimensional digital model is completed, render the digital model and project it in the form of 1:1 to confirm its shape and the proportion of the vehicle. After the above-mentioned confirmation that there is no large deviation, the clay model is made. Started joists, installed foam boards, trimmed foam boards, puttyed. The clay model is corrected according to the specific point data given by the three-dimensional data. After the clay model is completed, data scanning is performed to reversely complete the exterior surface and interior design of the car body.

[0021] 3D rendering figure 1 :1 projection is a relatively fast way to confirm the proportion of the vehicle, and can provide a more realistic viewing effect at the same time.

[0022] When the keel is made, the original frame platform is used for construction, which shortens th...

Embodiment 2

[0025] Under the condition that its steps remain unchanged, the sludge in the described sludge model making is composed of the following components by weight: 130 parts by weight of paraffin wax, 100 parts vaseline, 150-500 talcum powder, 6-7 stearic acid, first heating the paraffin wax, it melts Then add talcum powder, vaseline and stearic acid, and stir well. Making models and corrections is simple. The talcum powder is fed in 5-10 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com