A foam lightweight ball test piece molding device and test method

A technology of lightweight foam and molding devices, which is applied in ceramic molding machines, manufacturing tools, etc. It can solve the problems of poor homogeneity, light spherical test pieces, and surface depressions, etc., and achieves simple and easy testing and good stability. , good homogeneity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

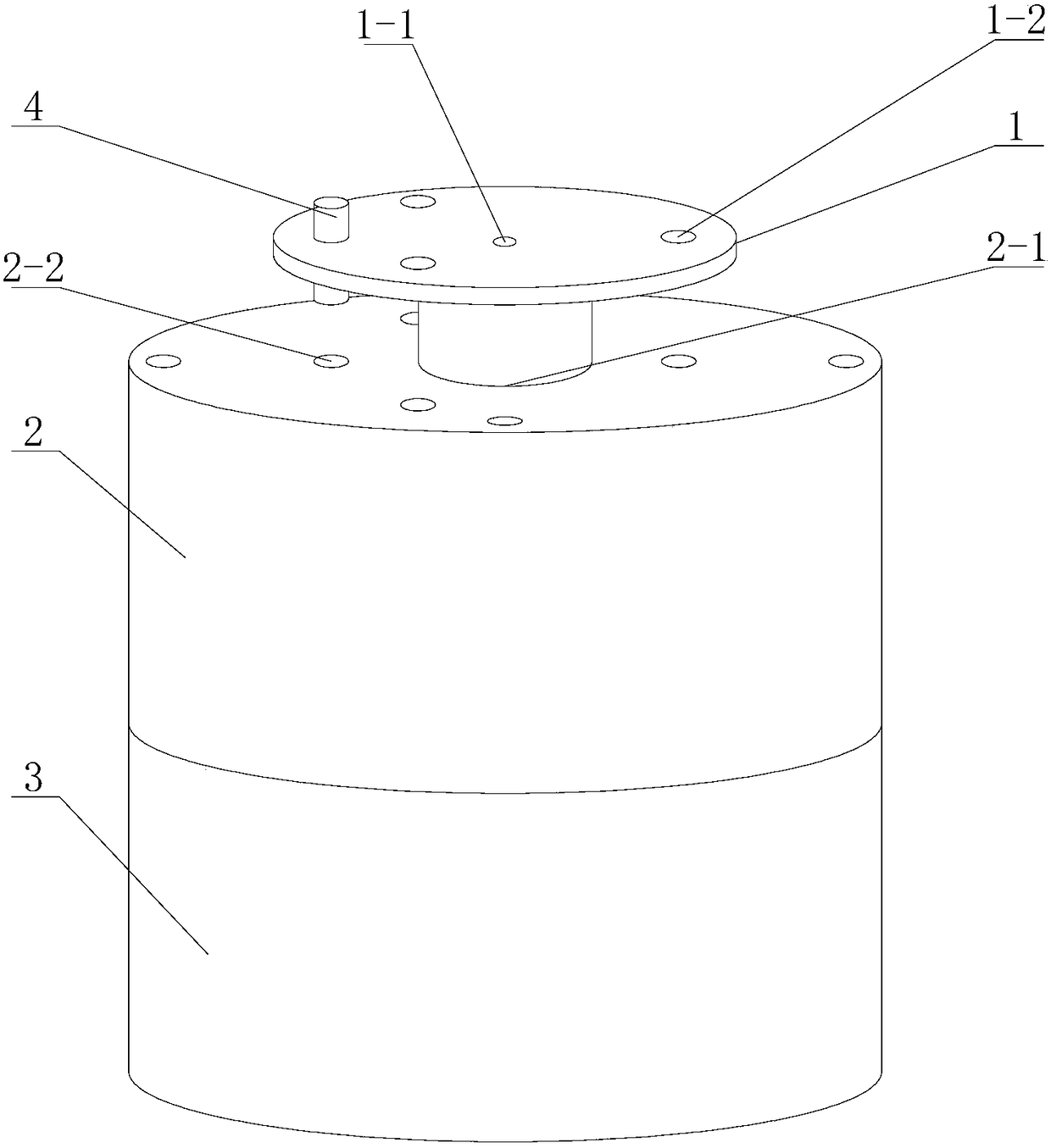

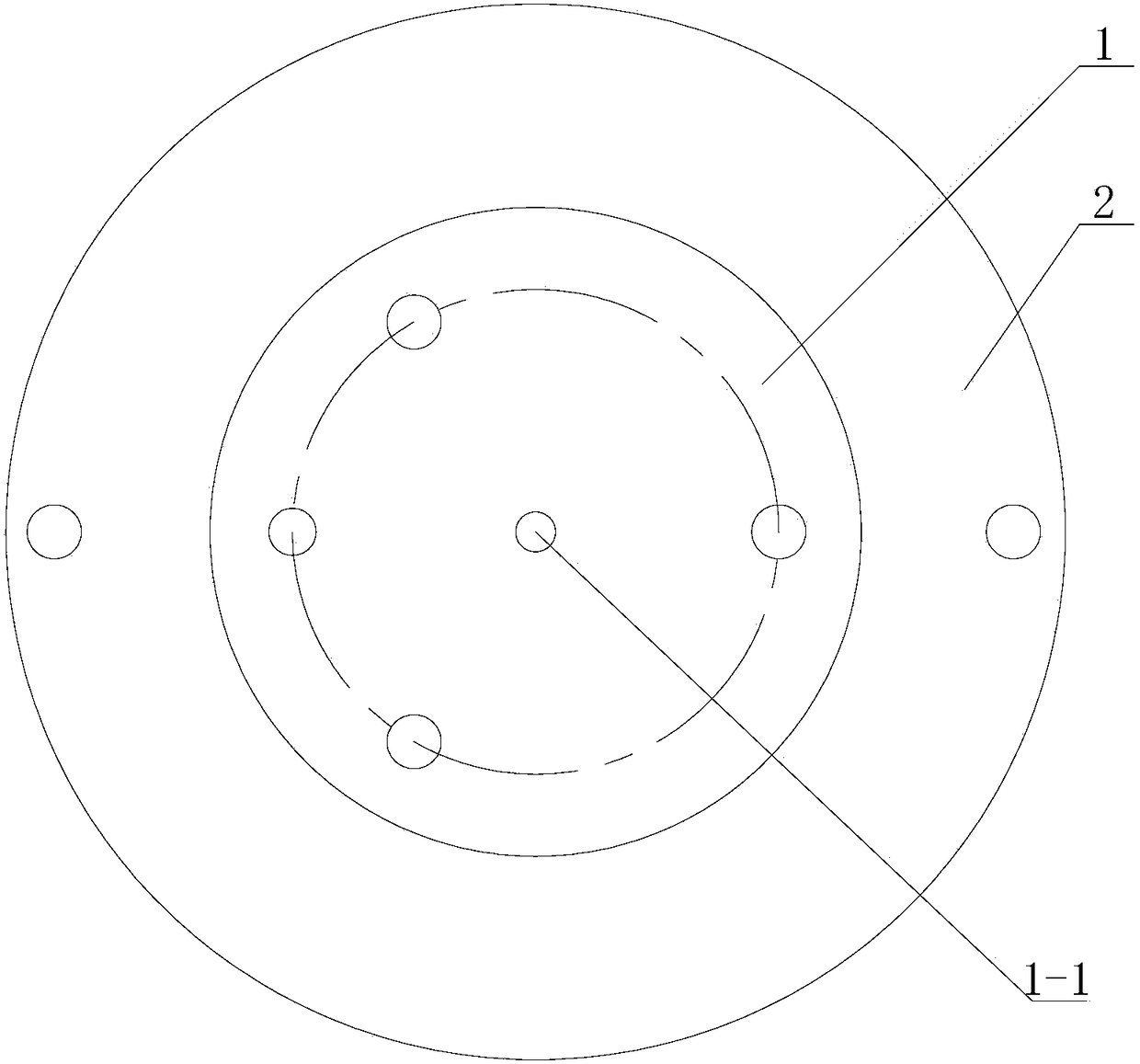

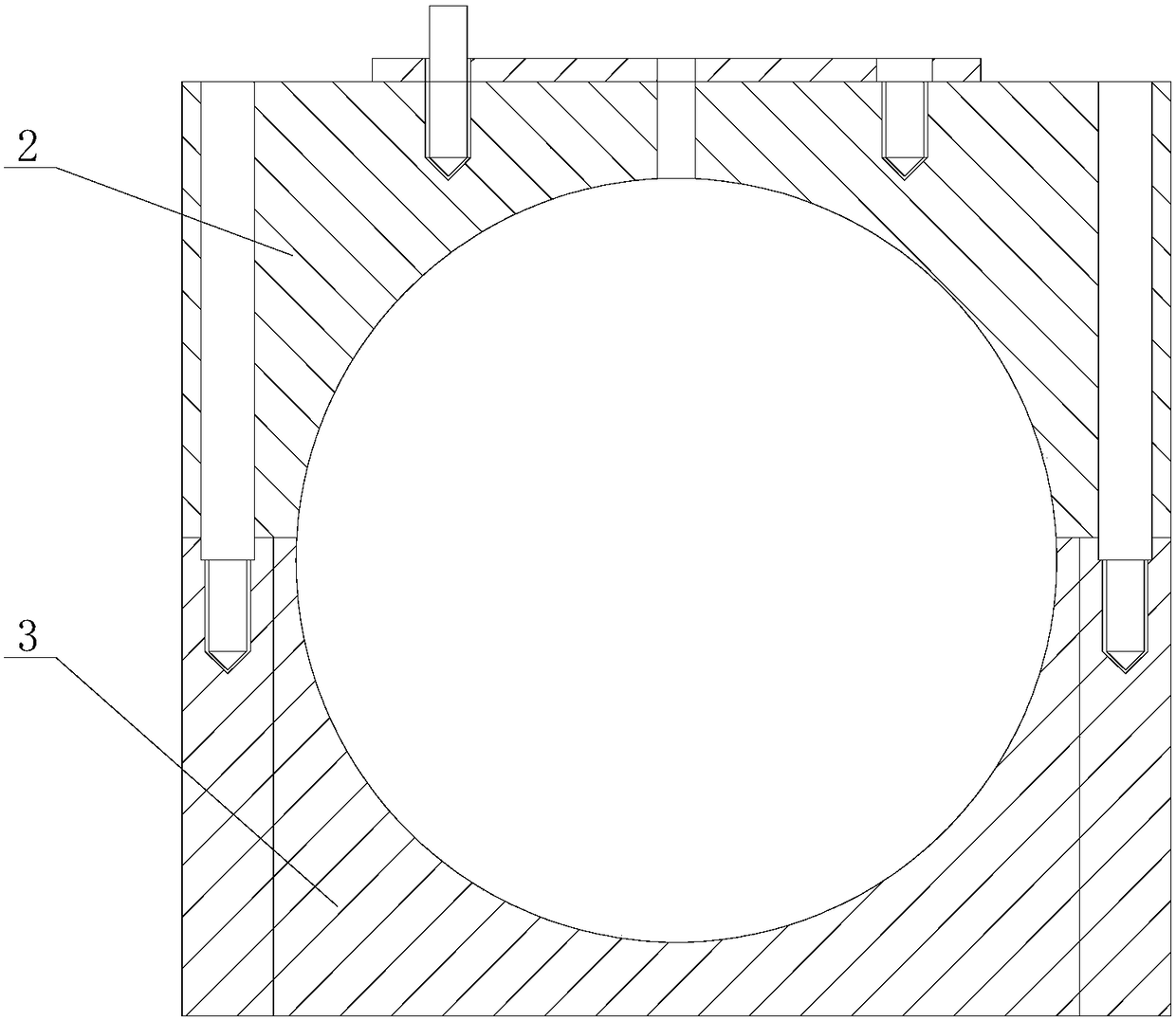

[0014] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment, a kind of foam lightweight ball test piece forming device described in this embodiment comprises top cover 1, upper hemisphere mold 2, lower hemisphere mold 3 and positioning pin 4, and upper hemisphere mold 2 and lower hemisphere mold 3 are formed by upper Connected sequentially from top to bottom, the upper surface of the upper hemispherical mold 2 is provided with a grouting port 2-1, the top cover 1 is installed on the grouting port 2-1, and the lower end of the positioning pin 4 passes through the top cover 1 and is inserted into the upper hemispherical mold 2 In the positioning pin hole 2-2 on the upper surface. The forming device described in this embodiment is used to process a spherical test piece with a diameter of 100mm, and the slurry is poured from the grouting port at the top of the upper hemisphere.

specific Embodiment approach 2

[0015] Specific implementation mode two: combination Figure 1 to Figure 3 To describe this embodiment, the upper surface of the top cover 1 of a foam lightweight ball test piece forming device described in this embodiment is provided with an excess slurry overflow port 1-1. In this embodiment, the slurry is poured to the grouting port, the top cover is pressed in and fixed, the excess slurry will flow out from the overflow port, and the spherical test piece is formed and completely closed, thereby avoiding the problem of defects on the top of the spherical surface. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0016] Specific implementation mode three: combination Figure 1 to Figure 3 To illustrate this embodiment, the upper surface of the top cover 1 of the foam lightweight ball test piece forming device described in this embodiment is provided with a plurality of top cover fixing threaded holes 1-2 evenly distributed along the circumferential direction. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com