Heating channel unit, method for producing a heating channel unit, and folding device

A heating channel and bending technology, which is applied in the direction of chemical instruments and methods, additive processing, layered products, etc., can solve the problems of heating channel unit or channel manufacturing difficulty, adding channel unit complex design, etc., to achieve less friction loss, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

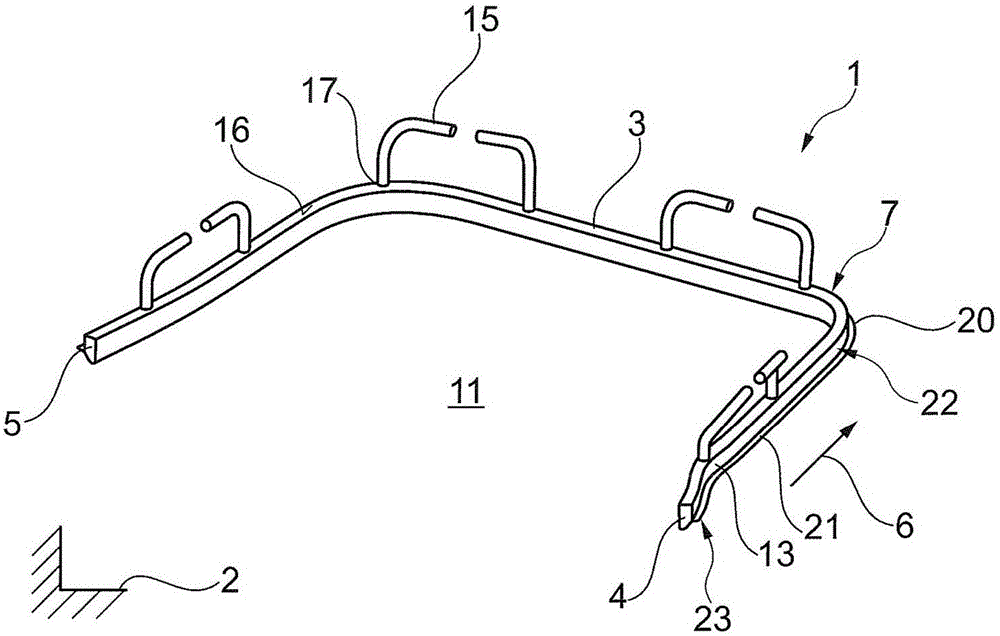

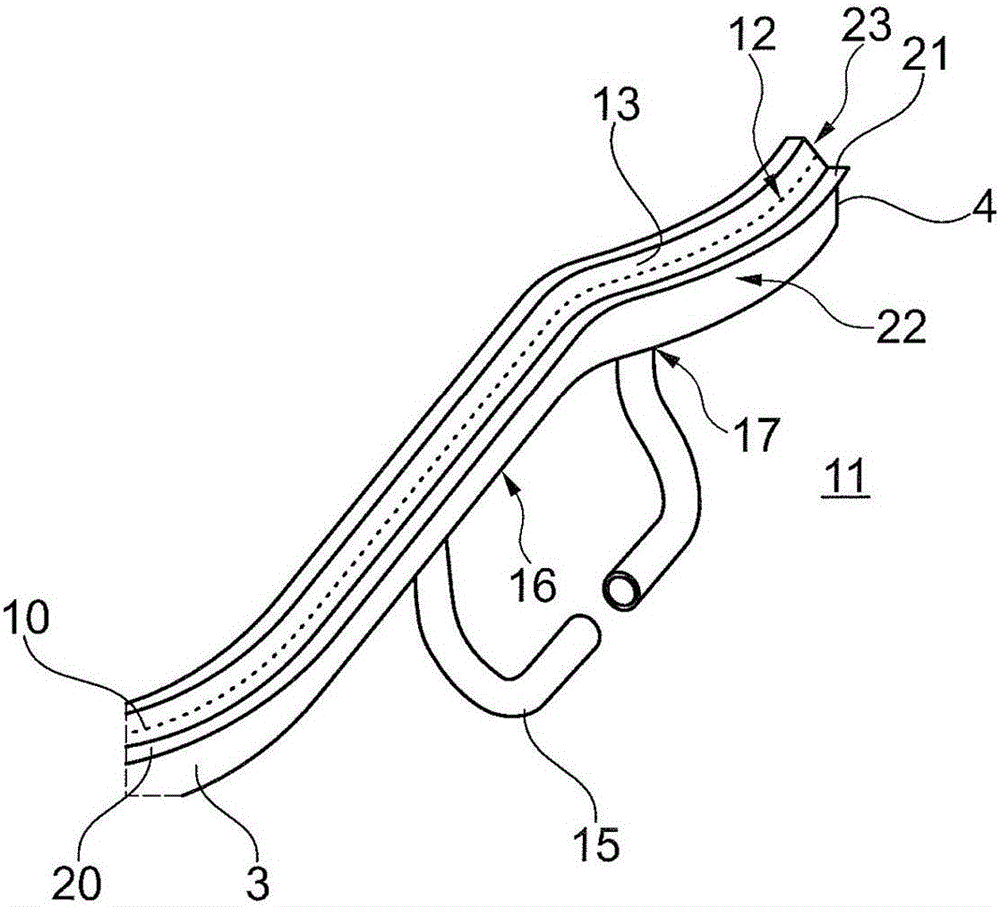

[0078] according to figure 1 and 2 The illustration of the channel 3 of the heating channel unit shows the presence of the bending device 2 which is not further shown here figure 1 The heating channel unit 1 shown in , wherein the bending device is used to bend the edge of the decorative layer around the carrier, and the channel is used to guide air heated at an air heater (not shown) or hot air (not shown here) marked in detail).

[0079] The channel 3 is substantially U-shaped and here has a contour that is three-dimensionally multiple times in space over the longitudinal extension 6 of the channel 3 from the first end 4 of the channel 3 to the second end 5 of the channel 3 bent, if able to figure 2 as seen in the .

[0080] At this point, the channels 3 of the heating unit 1 already have a somewhat complexly shaped channel course.

[0081] This channel 3 is thus an essential part 7 of the heating channel unit 1 .

[0082] as in the same figure 2 As can be clearly s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com