Elevator braking device and method

An elevator braking and motion technology, applied in the direction of the hoisting device, etc., can solve the problems of casualties, open the door and walk up the stairs, and reduce the contact surface, and achieve the effect of reducing casualties, avoiding safety failures, and occupying a small space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

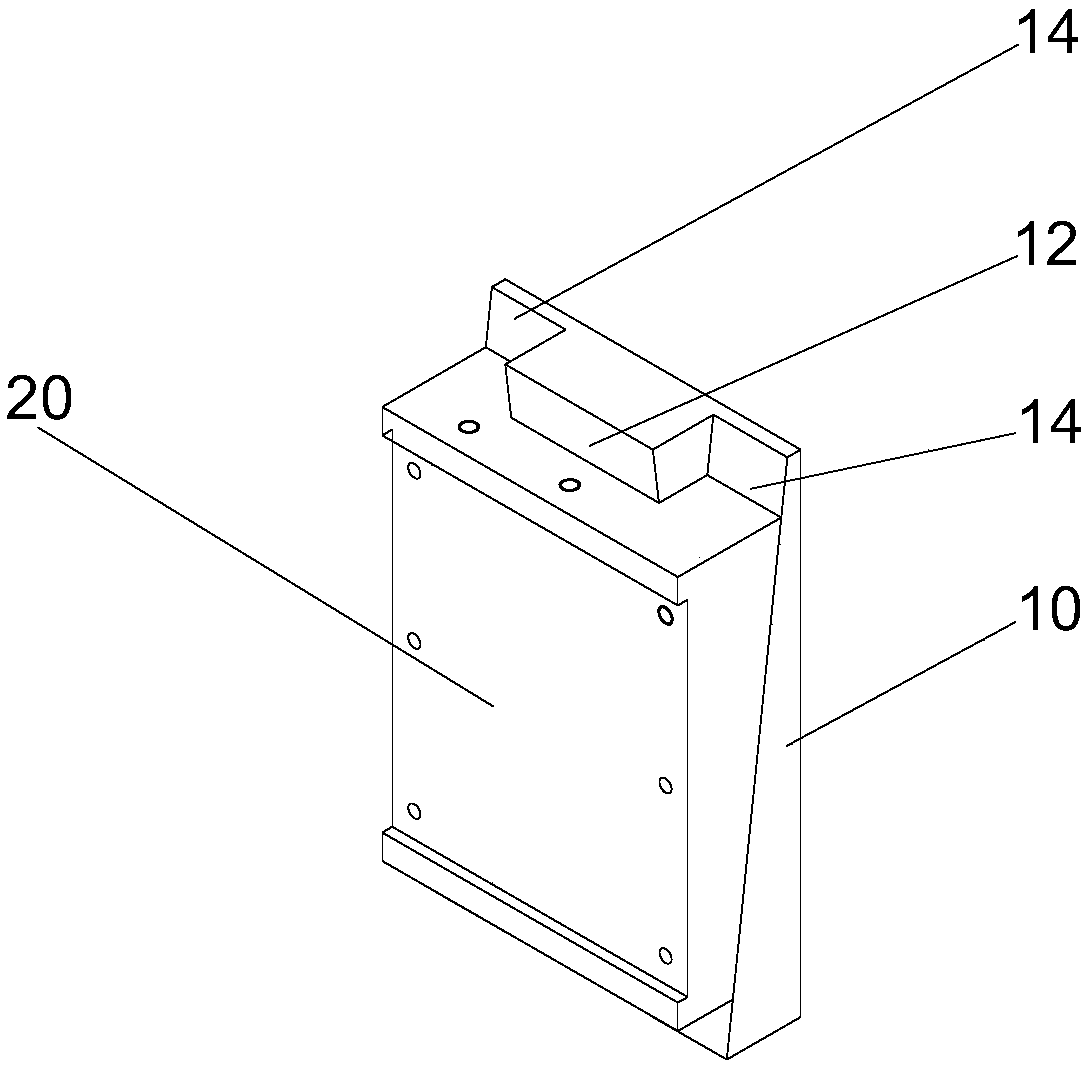

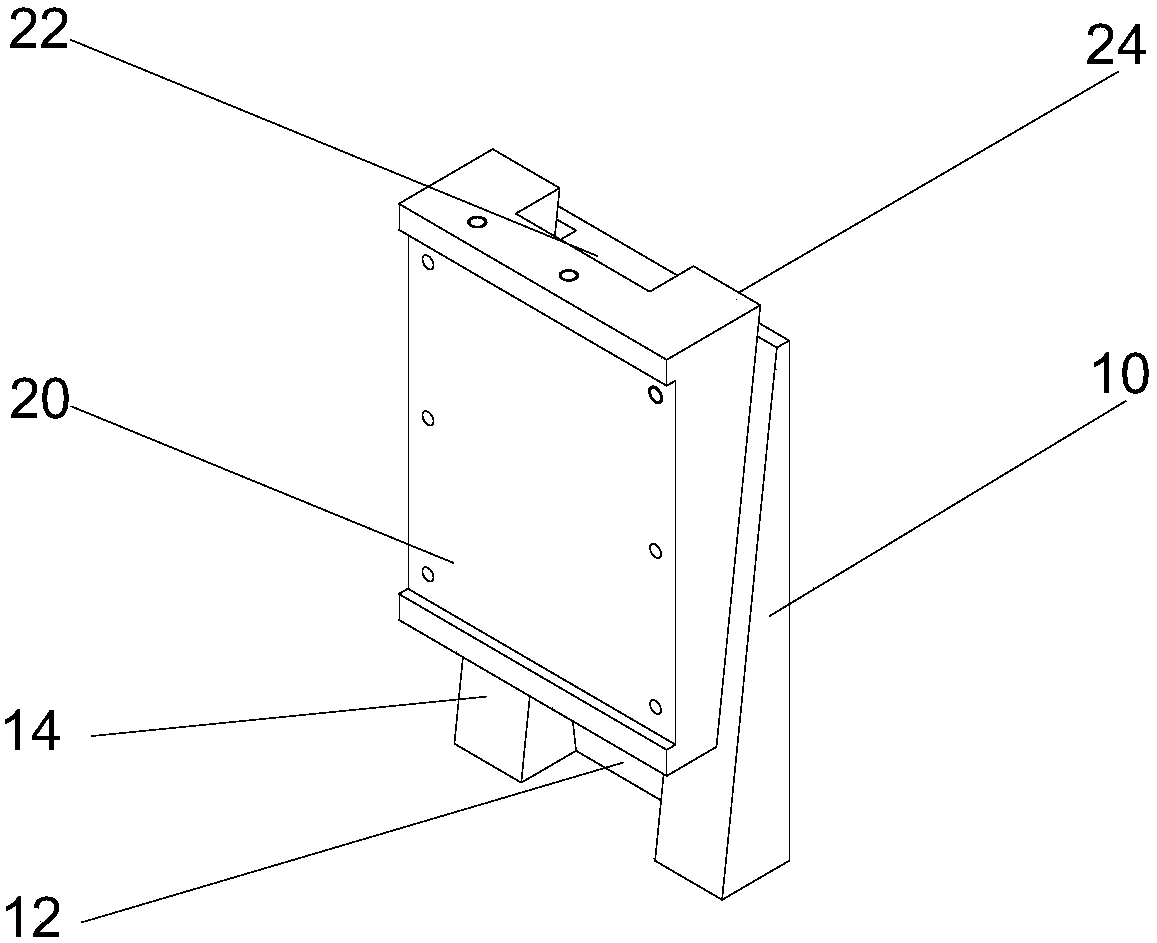

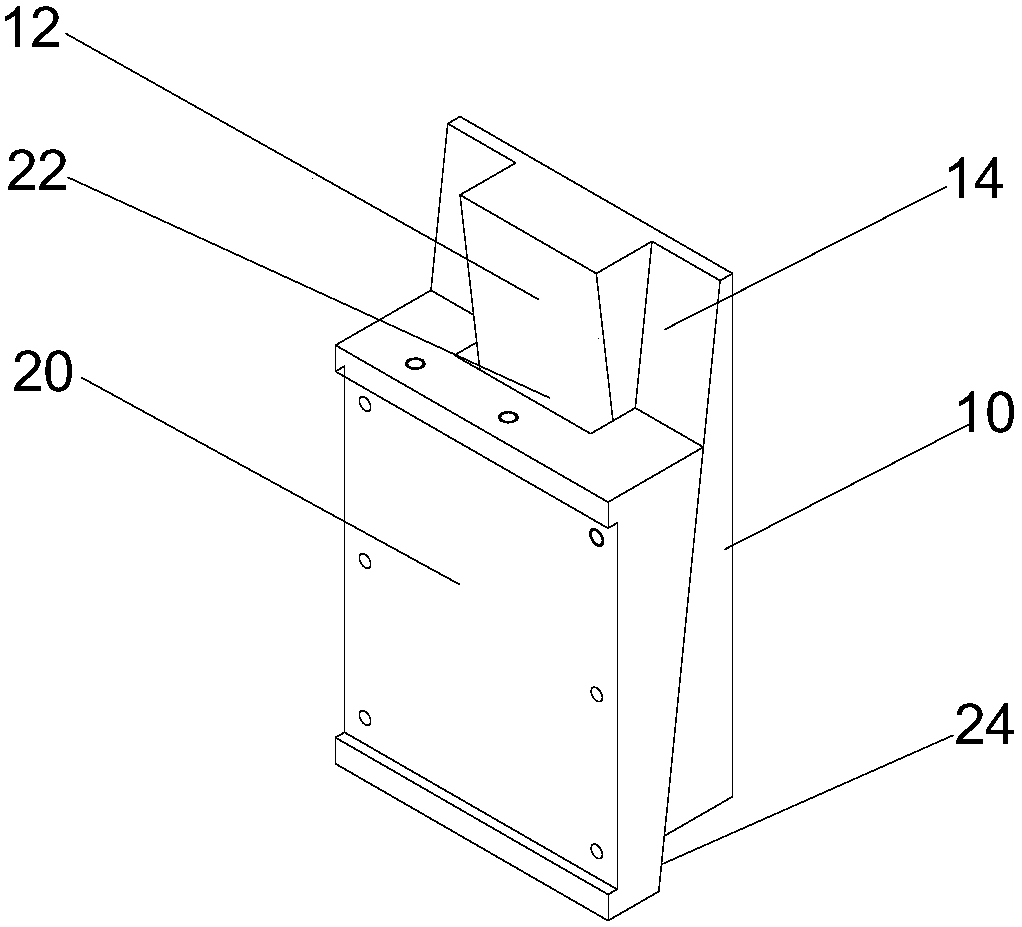

[0037] Example: such as Figure 1-8 As shown, the present invention provides a first embodiment of an elevator braking device, which is used for two-way braking of a steel wire rope 42 or a guide rail, comprising: at least one pair of fixed clips 10 that can reciprocate relative to the fixed clips 10 and At least one pair of movable clamping blocks 20 located on both sides of the steel wire rope 42 or the guide rail, the driving mechanism 30 for driving the movable clamping block 20 to move, and the friction plate 50 arranged on the movable clamping block 20 and in frictional contact with the steel wire rope 42 or the guide rail, wherein the fixed The clamping block 10 is provided with a first slope 12 on one side and a pair of second slopes 14 located on both sides of the first slope 12, and the movable clamping block 20 is provided with a third slope 22 cooperating with the first slope 12 on one side, And a pair of fourth slopes 24 correspondingly matched with the correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com