Coarse rack pull chain underwater steering structure capable of avoiding chain come-off and sticking

A thick grid and chain technology is applied in the field of underwater steering structure of thick grid traction chain, which can solve the deformation of the vertical shaft 5 or the side wall of the thick grid 1, the length of the traction chain 2 becomes longer, the traction chain 2 is de-linked, etc. problems, to achieve the effect of easy operation, avoid off-chain and stuck, and avoid off-chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific examples.

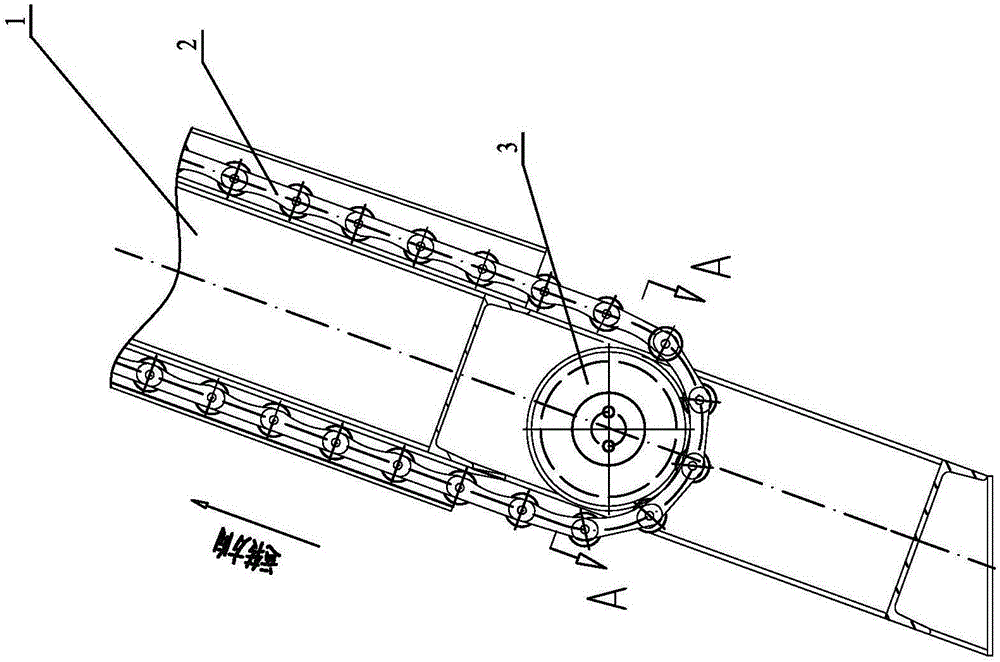

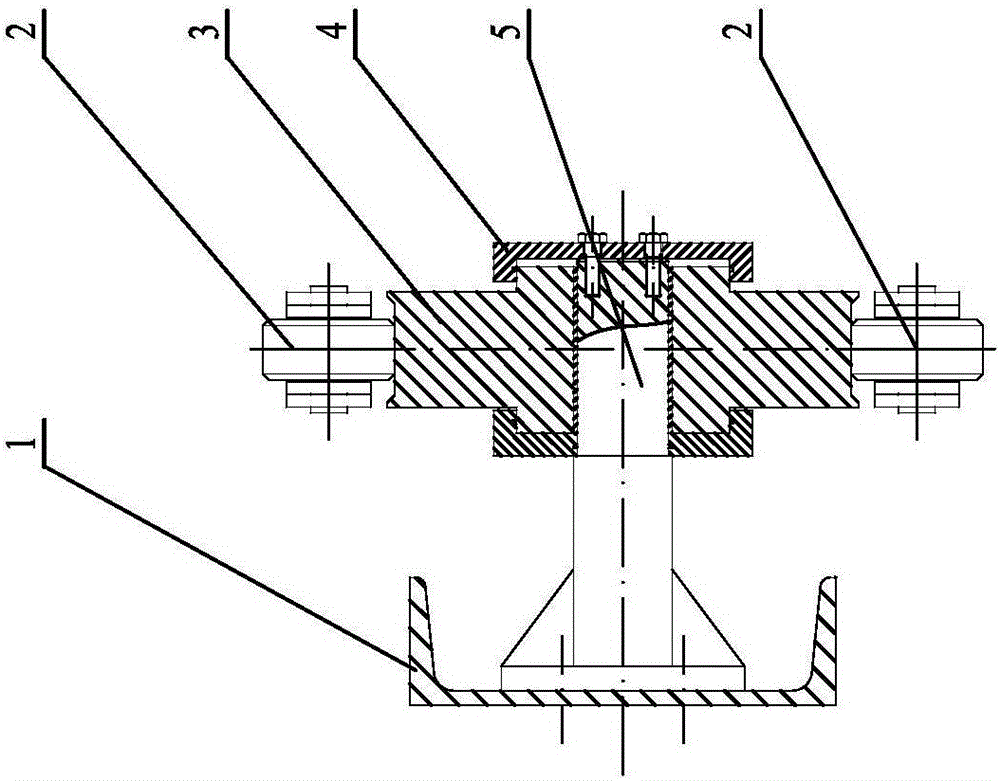

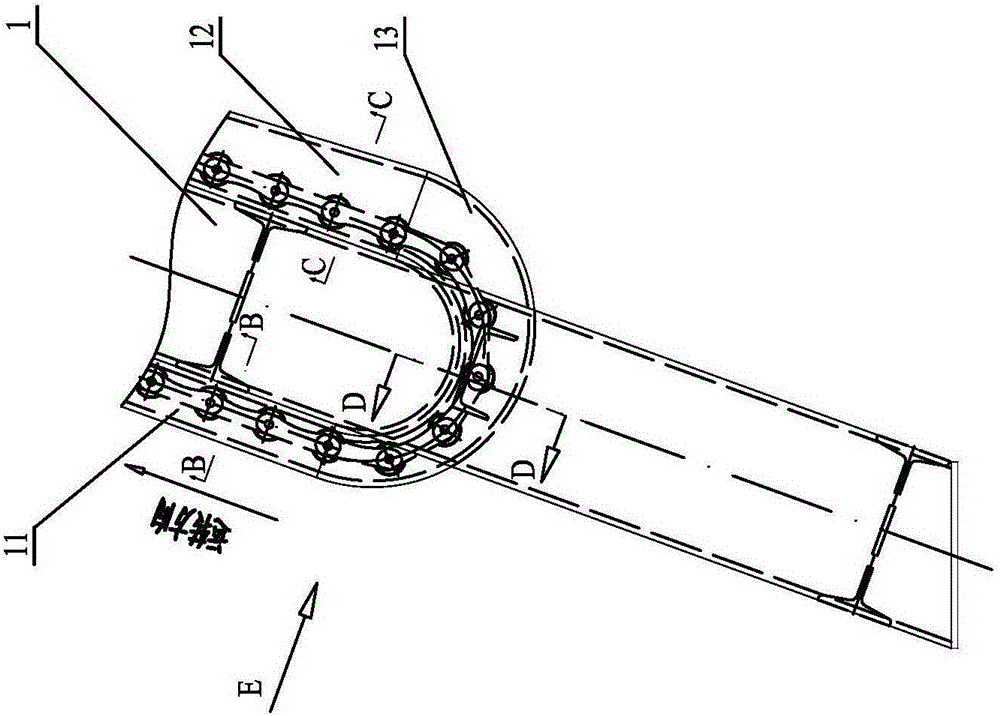

[0023] The underwater steering structure of the coarse grid traction chain that can avoid unchaining and jamming includes the coarse grid 1 and the traction chain 2, and also includes the linear chain groove 11 of the upward section, the linear chain groove 12 of the downward section and the arc-shaped chain groove. 13. The notches of the straight chain groove 11 in the uplink section, the straight chain groove 12 in the downlink section and the arc-shaped chain groove 13 are all facing inward, and the straight chain groove 11 in the uplink section is composed of the first upper slot plate 11.1, the first lower slot plate 11.2 The first connecting slot plate 11.3 is connected, the straight line chain slot 12 of the down section is formed by connecting the second upper slot plate 12.1, the second lower slot plate 12.2 and the second connecting slot plate 12.3, and the arc-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com