Zipper tooth oxidized wire with constant tension

A technology of oxidized thread and zipper, which is applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problems of uneven tension of chain belts, easy occurrence of unchaining, winding, etc., to achieve stable equipment, constant tension, and avoid unchaining Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

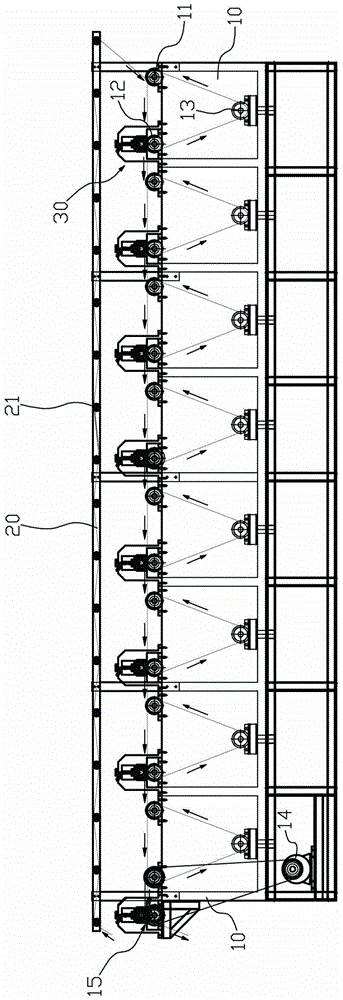

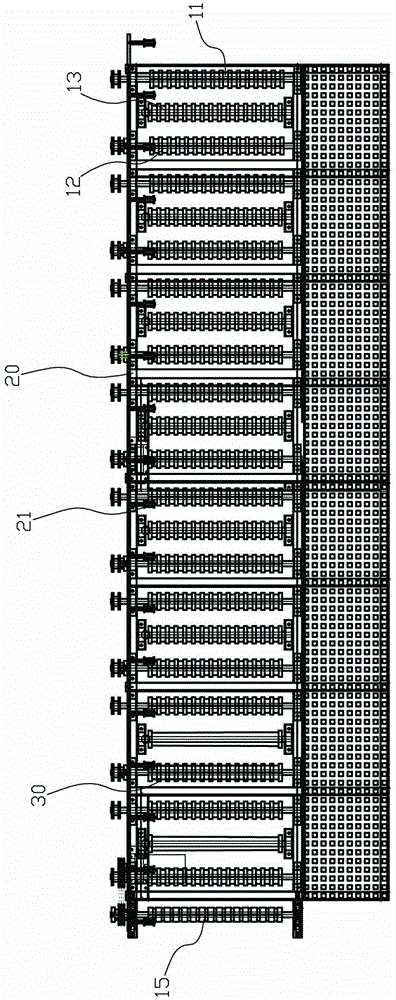

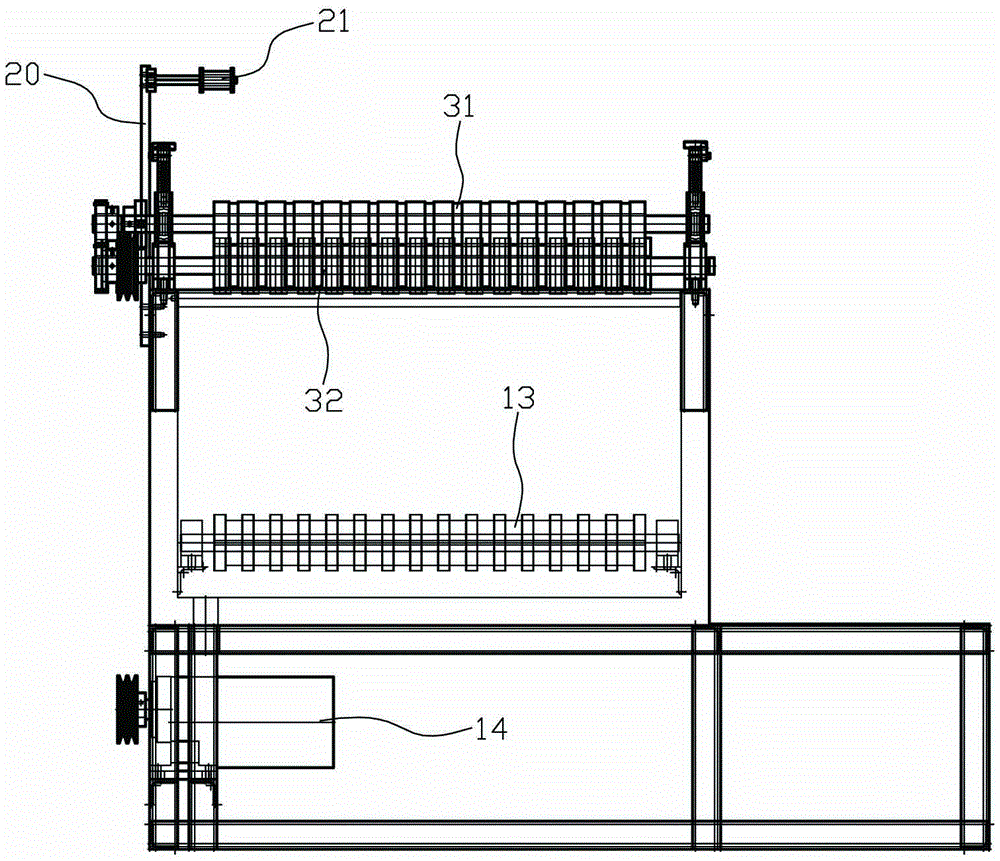

[0023] A zipper element oxidation thread with constant tension, refer to Figure 1 to Figure 3 , including an oxidation line main body, the oxidation line main body includes a plurality of oxidation tanks 10 arranged side by side and a support 20 arranged above the oxidation tank, and a plurality of freely rolling belt guide rollers 21 are arranged on the support 20 . Each oxidation tank 10 is at least provided with a tape-in drive shaft 11, a tape-out drive shaft 12 and a soaking roller 13, and the discharge end of the oxidation tank 10 at the end is provided with a motor 14 for pulling the zipper tape. A lead-out rotating shaft group 15, except the terminal oxidation tank 10, is also provided with a zipper belt traction device 30 at the outlet end of each oxidation tank 10, and each zipper belt traction device 30 is provided with a pressure and a zipper belt speed display The device (not shown in the figure) is used to display the pressure and speed that the zipper receive...

Embodiment 2

[0026] This embodiment is basically the same as Embodiment 1, the difference is that: refer to Figure 5 , between every two oxidation tanks 10 of the present embodiment, a support platform 50 with a certain width is provided, and the zipper belt traction device 30 is arranged on the support platform 50, and the lower traction pulley 32 is connected with the belt drive shaft 11, Go out with driving shaft 12 and be on the same straight line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com