Shallow-embedded drip irrigation belt recycling machine

A technology of drip irrigation belt and recycling machine, which is applied in the directions of winding strips, thin material processing, transportation and packaging, etc., and can solve the problems of weed entanglement and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

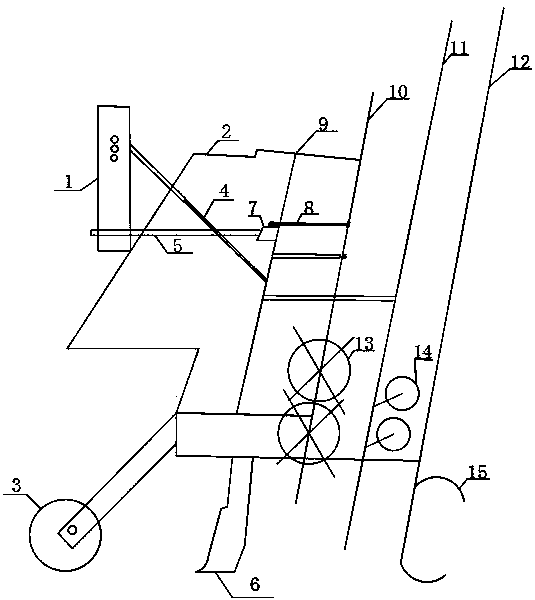

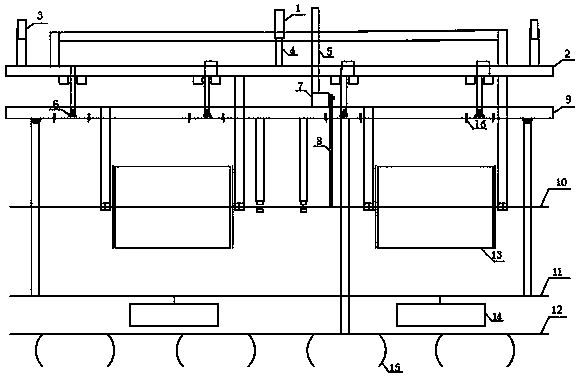

[0010] Such as figure 1 and figure 2 As shown, a shallow-buried drip irrigation belt recovery machine includes a structural frame, a ditching device, a transmission device and a recovery device.

[0011] Ditching device is made up of depth-limiting wheel 3 and ditching plowshare 6, and transmission device is made up of transmission shaft 5, gearbox 7 and sprocket wheel 8, and recovery device comprises tape shaft 13, guide belt shaft 14 and guide belt ring 15 and forms.

[0012] The front section of the structural frame 2 is provided with a suspension interface 1. The structural frame 2 is arranged in sequence from front to back with 9, 10, 11, and 12 four beams. The beam 9 is a square steel structure, and the beams 10, 11, and 12 are round steel structures. The suspension interface 1 A hydraulic rod 4 is installed between the beam 9.

[0013] A depth-limiting wheel 3 and a ditching plowshare 6 are respectively arranged on the bottom of the left and right sides of the struct...

Embodiment 2

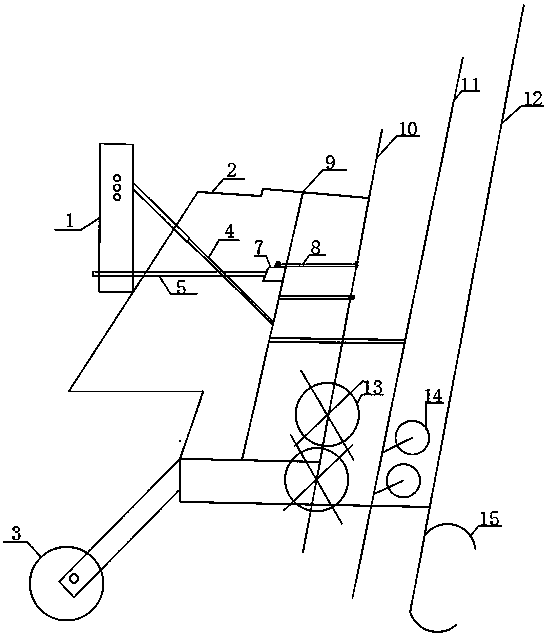

[0023] Such as image 3 As shown, compared with the structural schematic diagram of embodiment 1, the difference of embodiment 2 is that there is no furrowing plowshare 6, and this type is suitable for the recovery of the surface drip irrigation belt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com