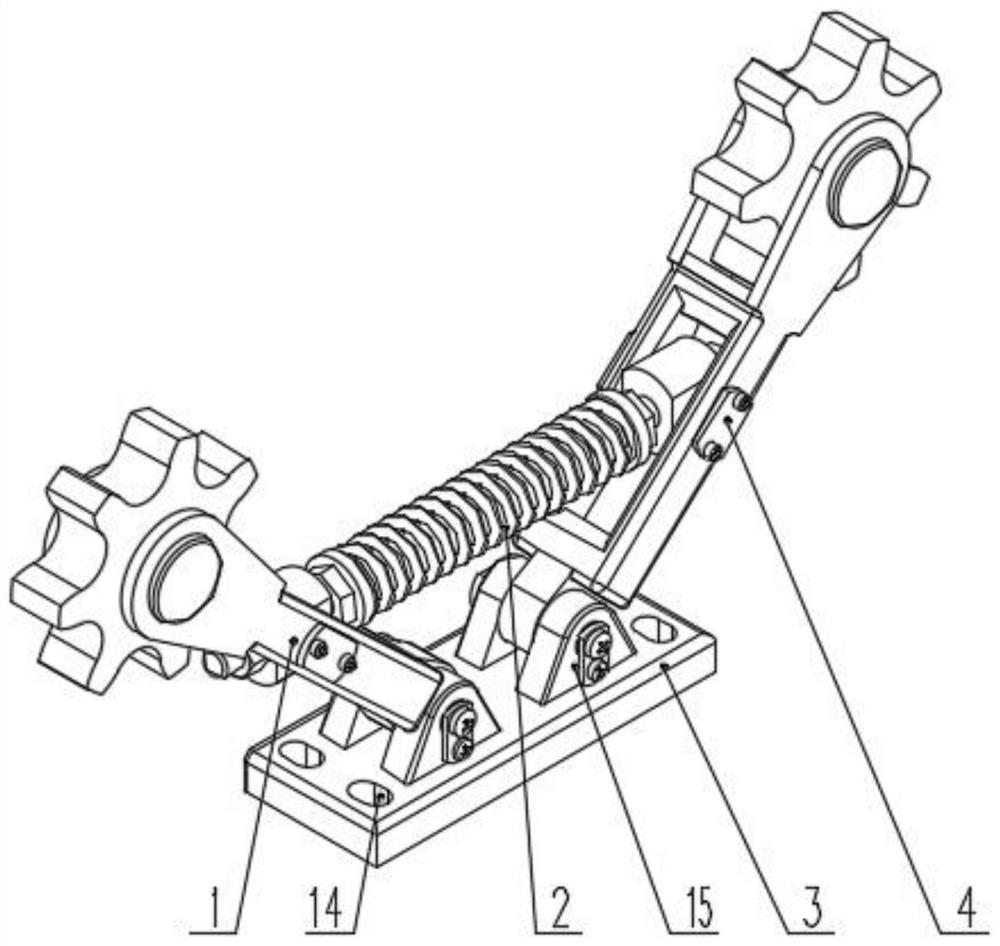

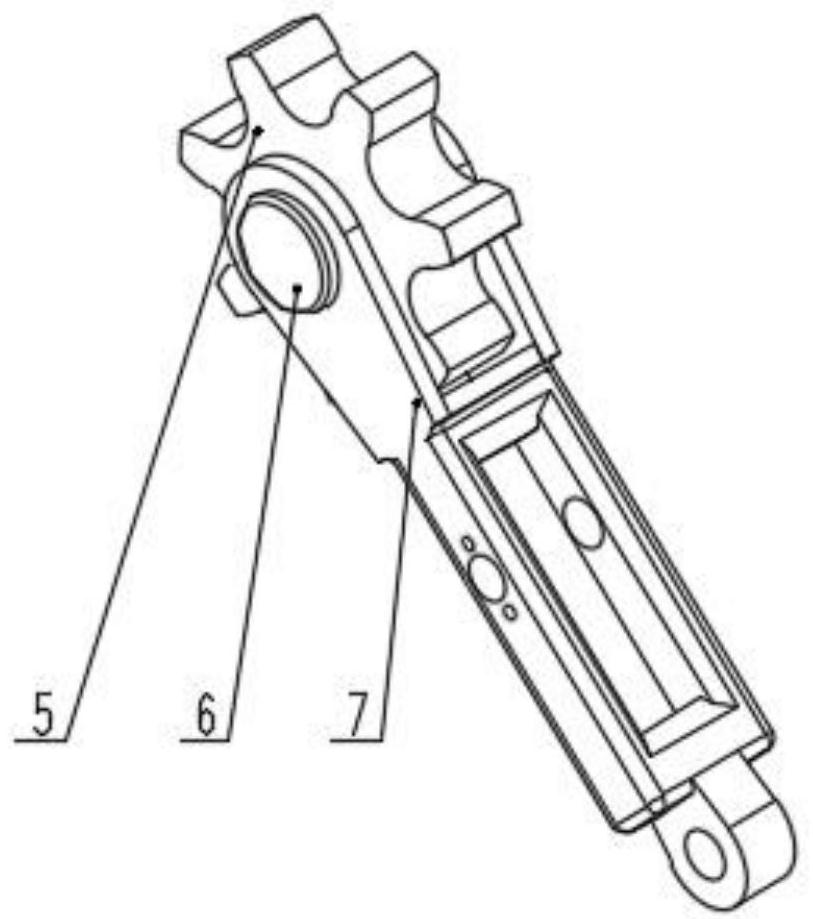

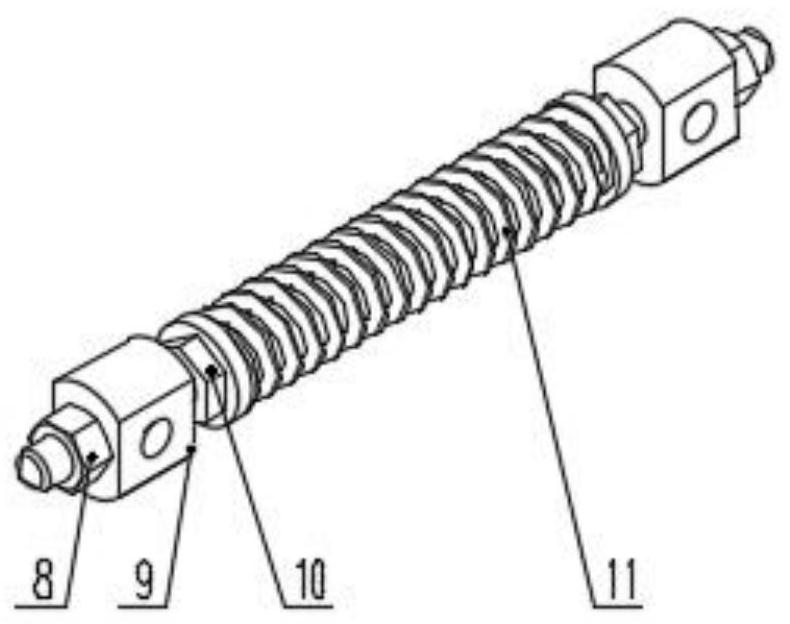

Flexible chain tensioning device

A technology of tensioning device and flexible chain, which is applied in the direction of transmission device, belt/chain/gear, mechanical equipment, etc., can solve problems affecting work efficiency, potential safety hazards, elongation and slack, etc., to improve work efficiency and prevent sprocket Off-chain, reducing the effect of potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0033] Implementation method: Before pre-installing the flexible chain tensioning device, adjust the adjusting screw so that the two swing arm rods are at the maximum angle under the unstressed state, and ensure that the pre-assembly angle of the two swing arm rods is greater than 100°, so as to improve the tension. Compensation amount, at this time the spring is in an unstressed state. The installation base plate and the preset mounting bracket (not described) are fixed by fixing bolts passing through the waist-shaped mounting holes 14, and the design of the waist-shaped mounting holes can be used to fine-tune the installation position. Apply outward pulling force to the two swing arm levers to increase the angle between the two swing arm levers. At this time, the spring is in a stretched state, and the tensioning sprocket at the end of the swing arm lever cooperates with the chain to be tensioned, and the external force is removed. Such as Figure 8 As shown, during the ten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com