Presser foot of a single-needle sewing machine

A technology of sewing machine and presser foot, which is applied to the thread cutting mechanism, sewing machine components, sewing equipment, etc. in the sewing machine, which can solve the problems of broken thread at the beginning of sewing, failure to press the fabric well, broken thread, etc., and reach the length of the thread end short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

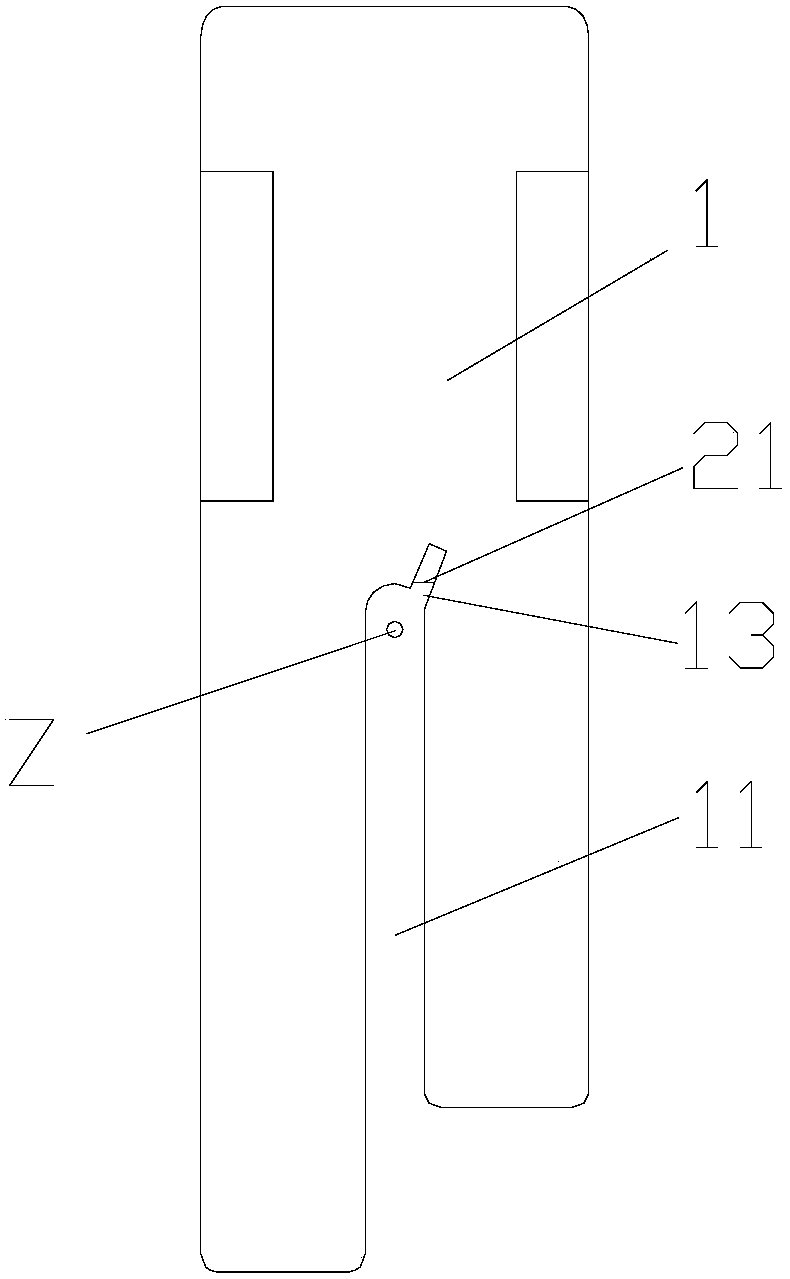

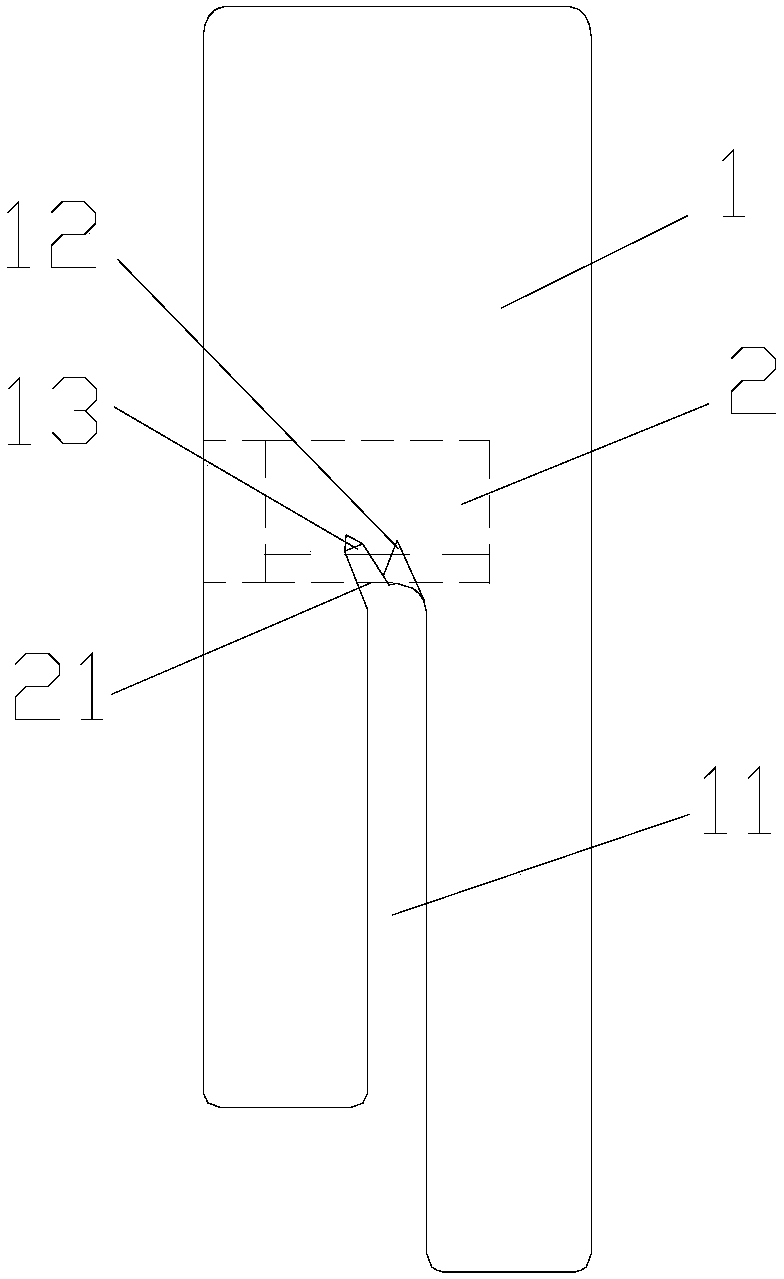

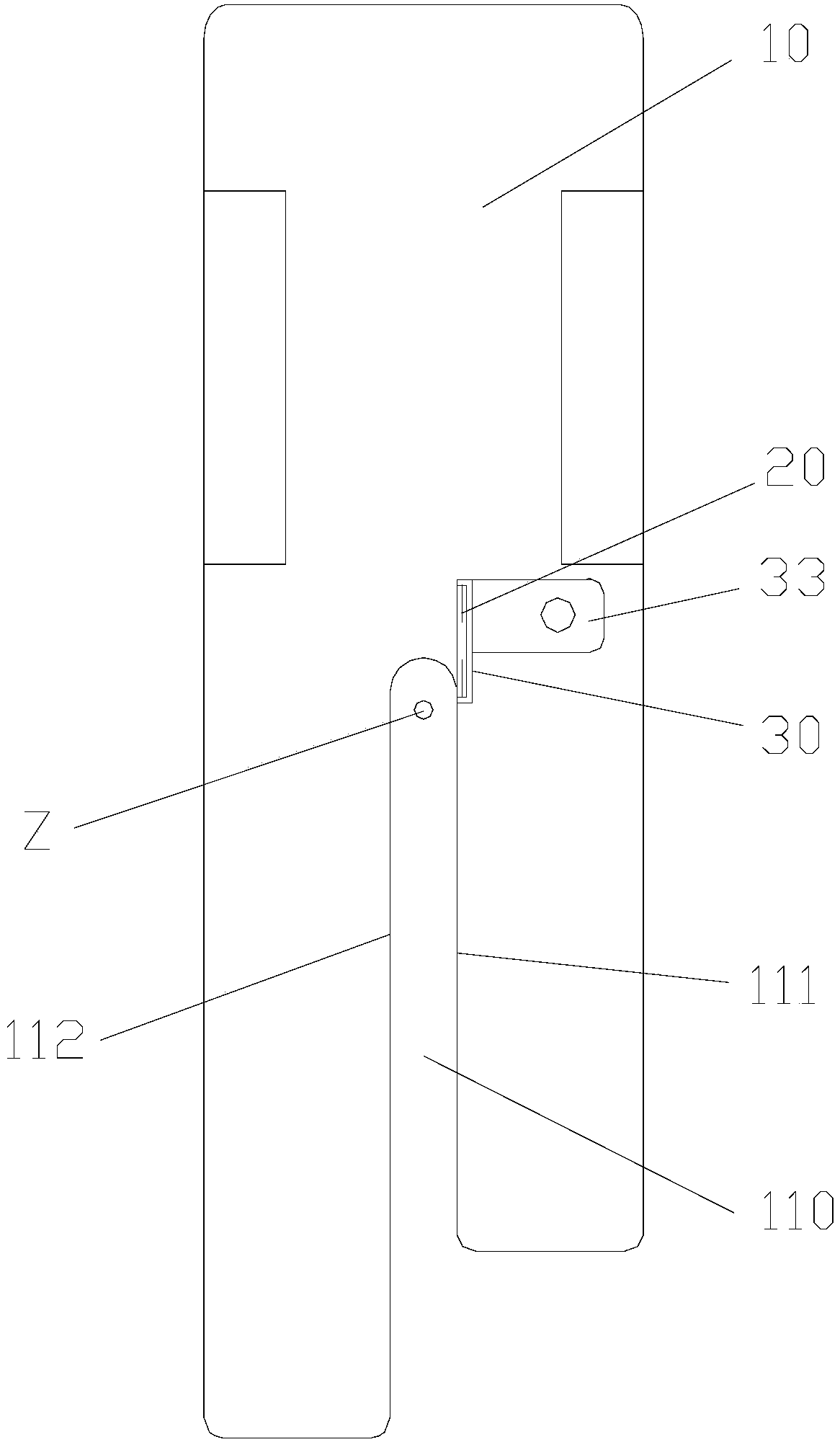

[0028] see Figures 3 to 8 , a presser foot of a single-needle sewing machine, including a presser foot plate 10, a cutter 20 and a thread protector 30.

[0029] The presser foot plate 10 is provided with a pinhole 110 that extends straight from the rear to the front edge and is open. The bottom surface of the presser foot plate 10 has a wire receiving groove 120 that extends backward from the rear end of the pinhole 110. The cutter 20 is erected and fixed on the On the surface of the presser foot plate 10, the front end of the cutting knife 20 has a blade 21, and the blade 21 extends vertically. The blade 21 is located on the left edge 112 or the right edge 111 of the pinhole 110, in this embodiment it is on the right edge 111, as figure 1 shown. The pinhole 110 is provided with an indented groove 130 on the right edge 111 of the correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com