A cold start device for an oil circuit system

An oil circuit system and cold start technology, which is applied to engine components, engine start, machine/engine, etc., can solve problems such as oil circuit cold start that cannot be completely solved in alpine regions, and achieve the effect of solving heating problems and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

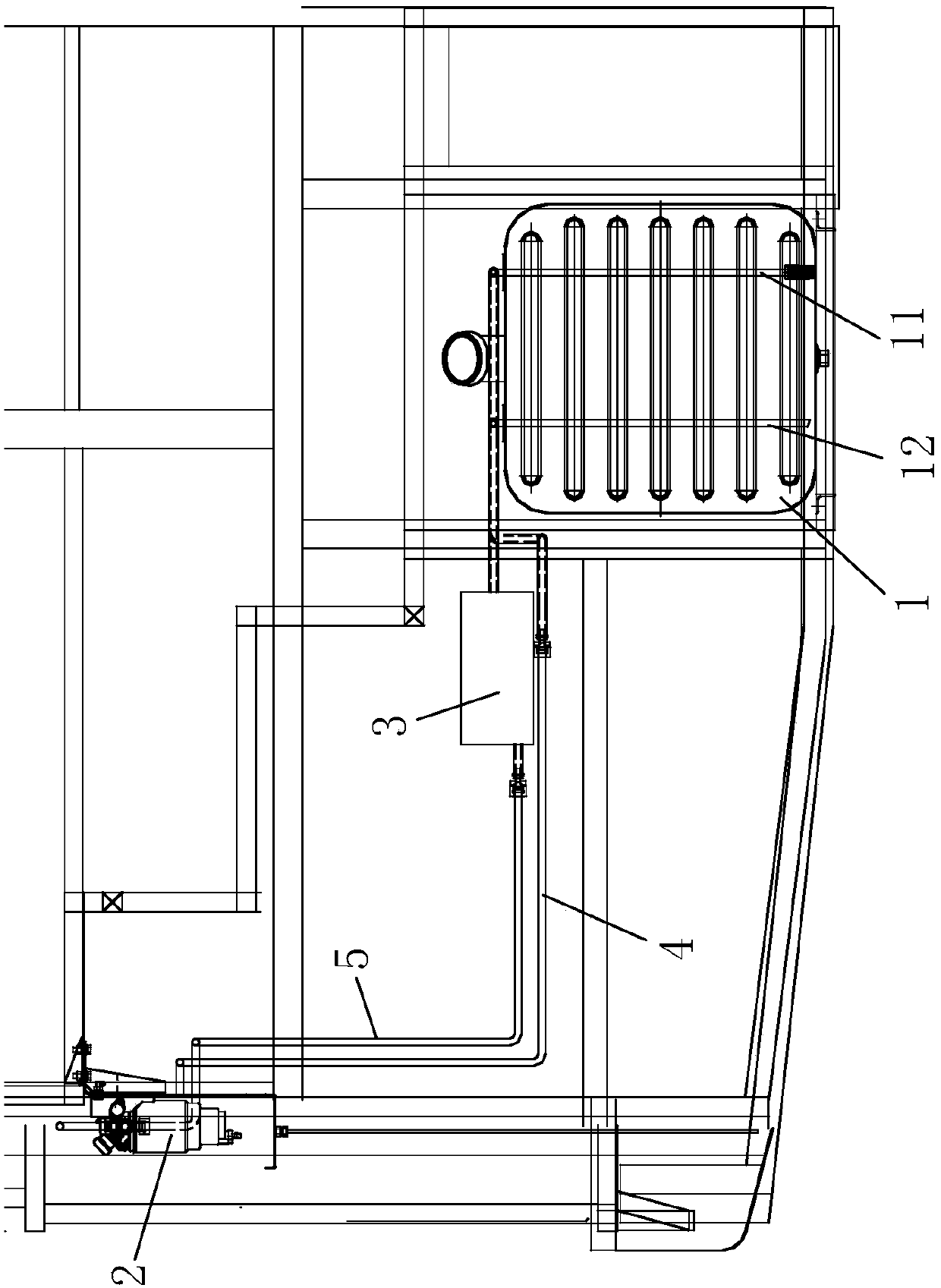

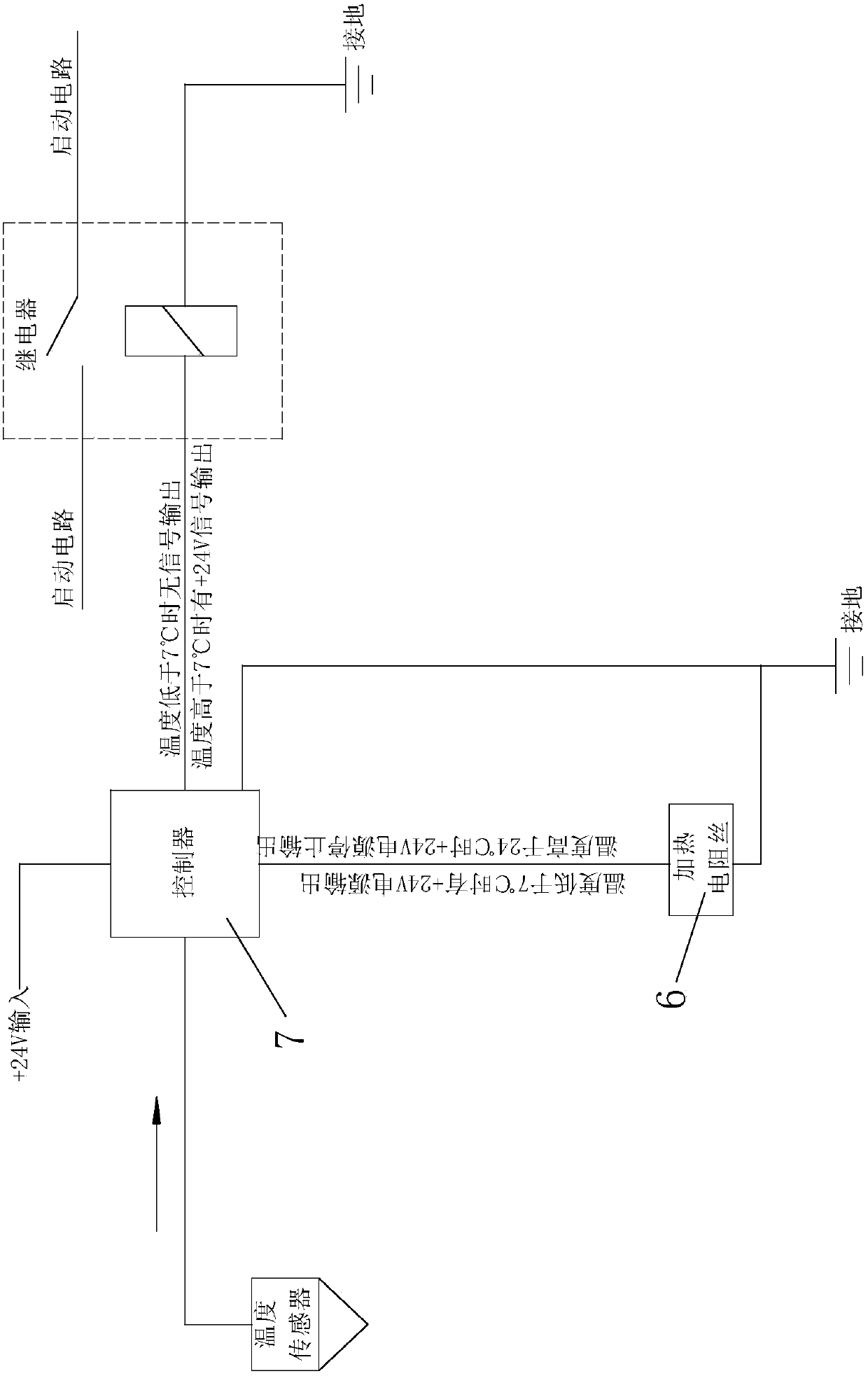

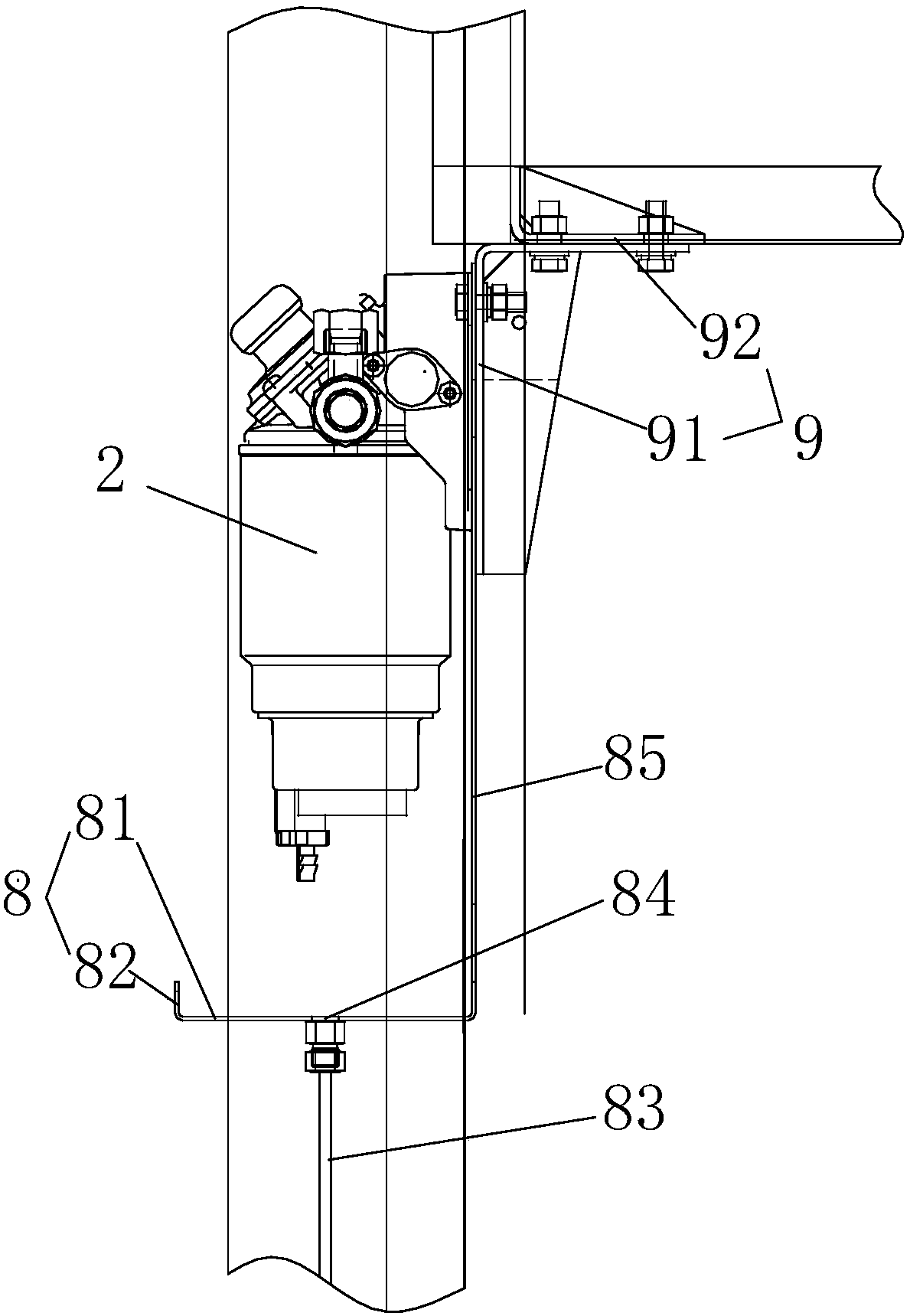

[0015] Such as figure 1 , figure 2 The cold start device of the oil circuit system shown includes a fuel tank 1, a fuel filter 2 and an engine 3, and a first fuel pipeline connecting the fuel tank 1 and the inlet of the fuel filter 2 is provided 4. There is a second fuel line 5 connecting the outlet of the fuel filter 2 and the oil inlet of the engine 3. The first fuel line 4 and the second fuel line 5 are equipped with heating resistance wires 6. A first temperature sensor and a second temperature sensor are installed in the first fuel pipeline 4 and the second fuel pipeline 5 respectively, the first temperature sensor and the second temperature sensor are connected to the controller 7, and the output terminal of the controller 7 It is connected with the heating resistance wire 6, and the controller 7 is connected with the vehicle power supply.

[0016] Further, the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com