Refrigerator and defrosting method for refrigerating chamber of refrigerator

A technology for refrigerated rooms and compartments, which can be used in defrosting, household refrigeration equipment, household appliances, etc., and can solve the problem that frost cannot be completely melted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

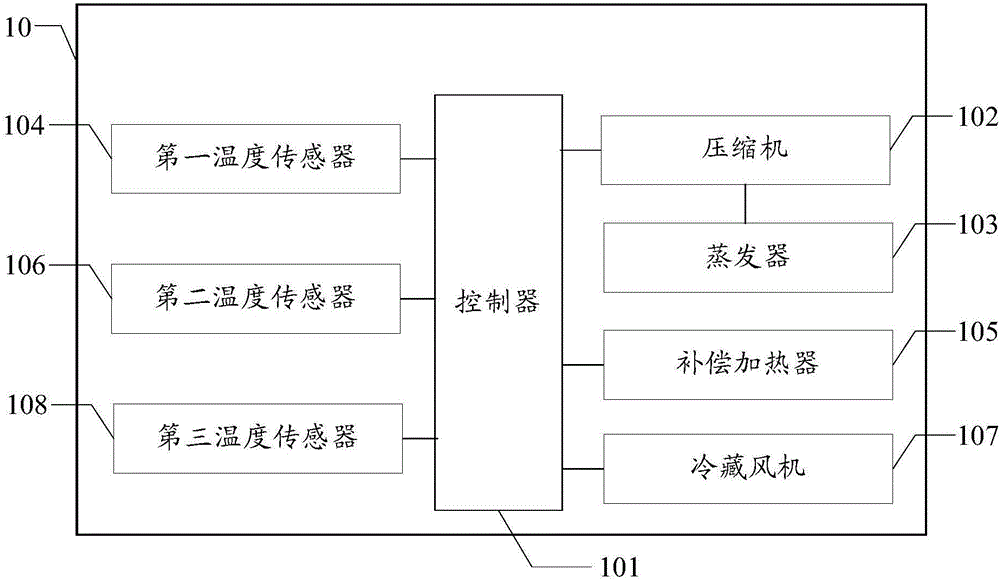

[0032] An embodiment of the present invention provides a refrigerator 10, combined with figure 1 As shown, the refrigerator 10 includes a refrigerator compartment, a freezer compartment, a controller 101 , a compressor 102 and an evaporator 103 .

[0033] A first temperature sensor 104 is installed in the freezer compartment, and the first temperature sensor 104 is used to measure the temperature value TF in the freezer compartment.

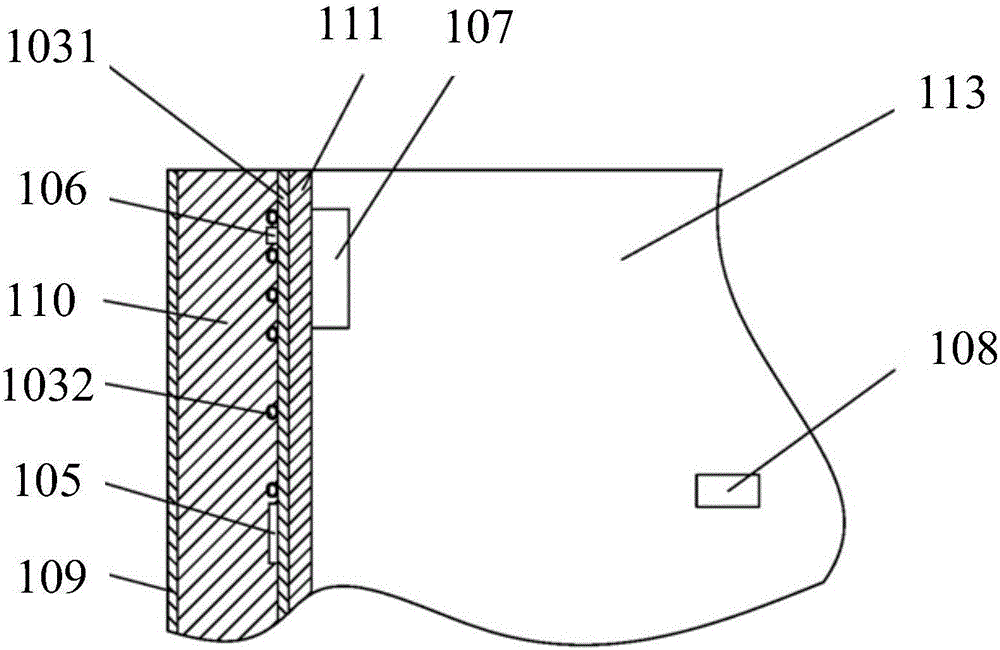

[0034] combine figure 2 In the side view of the refrigerated compartment shown, the back panel 109 of the refrigerator 10 is bonded to one side of the insulation layer 110, and the other side of the insulation layer 110 is bonded to the evaporator 103 ( figure 2 not marked). One side of the heat exchange plate 1031 of the evaporator 103 is bonded to the back liner 111 of the refrigerated compartment, and the other side is equipped with a compensation heater 105 and a second temperature sensor 106, and the compensation heater 105, the second t...

Embodiment 2

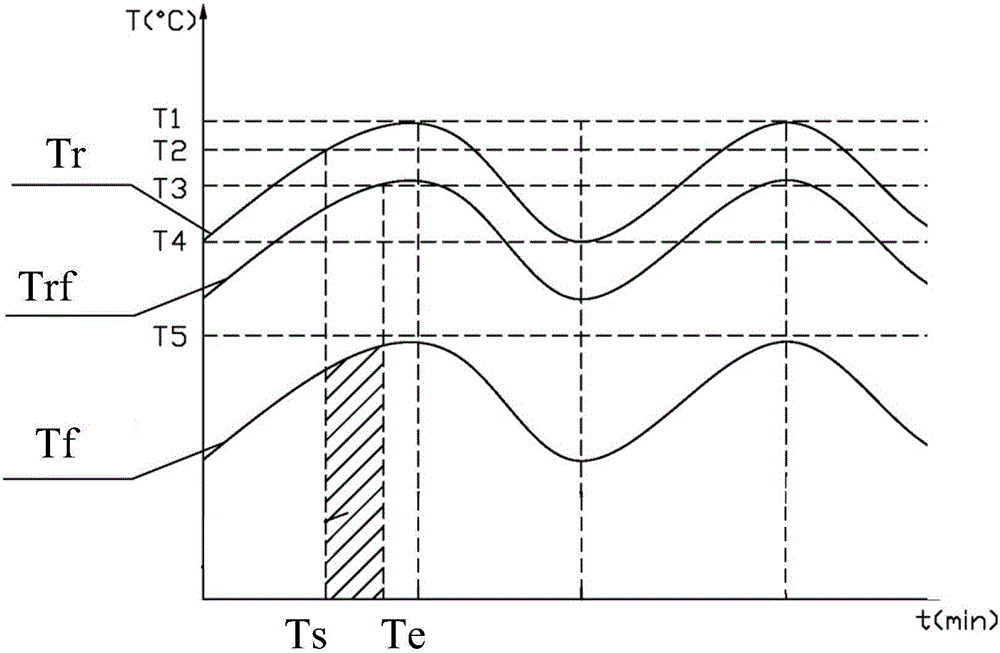

[0061] Embodiment 2 of the present invention provides a method for defrosting the refrigerated compartment of a refrigerator, which is applied to the refrigerator described in Embodiment 1. The refrigerator includes a refrigerated compartment, a frozen compartment, a compressor, and an evaporator, and the heat exchange plate of the evaporator One side is attached to the inner liner of the refrigerated room, and a compensation heater is installed on the other side. combine Figure 5 shown, including the following steps:

[0062] 501. Acquire the temperature value TF in the freezer compartment and the temperature value Trf on the surface of the heat exchange plate of the evaporator.

[0063] combine Figure 1 to Figure 4 In the corresponding embodiment, the refrigerator may measure TF through the first temperature sensor, and measure Trf through the second temperature sensor, and the temperature sensor may send the measured results to the controller of the refrigerator.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com