Experimental apparatus drying device

The technology of an experimental instrument and a drying device, which is applied in the direction of drying, drying machine, heating device, etc., can solve the problems of difficulty in keeping the drying device and experimental table clean, inconvenient users, long time, etc., and achieve fast and effective drying. The effect of drying, keeping clean and hygienic, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

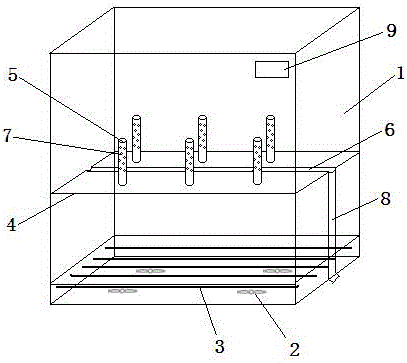

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] like figure 1 A drying device for experimental instruments shown includes a drying box 1, which is characterized in that: the bottom of the drying box 1 is provided with an upward blowing fan 2, and the upper part of the fan 2 is provided with a heating wire 3, Used to generate hot air; one or more drying plates 4 are horizontally arranged in the middle of the drying box 1, and the drying plates 4 divide the interior of the drying box 1 into upper and lower isolated spaces, and the drying plates 4 is provided with a plurality of air outlets 5 standing upright, and the air outlets 5 are a bottom-top through structure for placing experimental instruments to be dried.

[0014] Further, the drying plate 4 is provided with drainage grooves 6, and the drainage grooves 6 discharge excess water to be discharged to the outside of the drying box 1 through the pipe 8, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com