Wheel-type dry coupling ultrasonic thickness measuring probe

A dry-coupling and ultrasonic technology, which is applied in the field of wheel-type dry-coupling ultrasonic thickness measurement probes, can solve problems affecting thickness measurement accuracy, dry coupling layer detachment, dry coupling layer torsional deformation, etc., to prolong life, ensure accuracy, and reduce wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

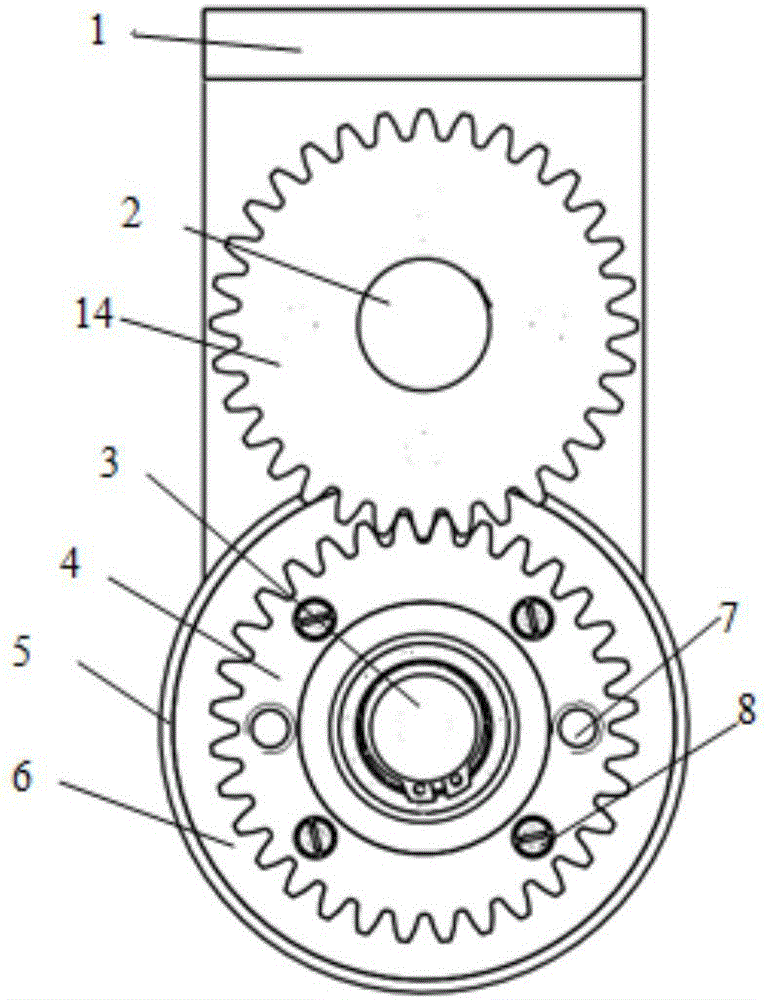

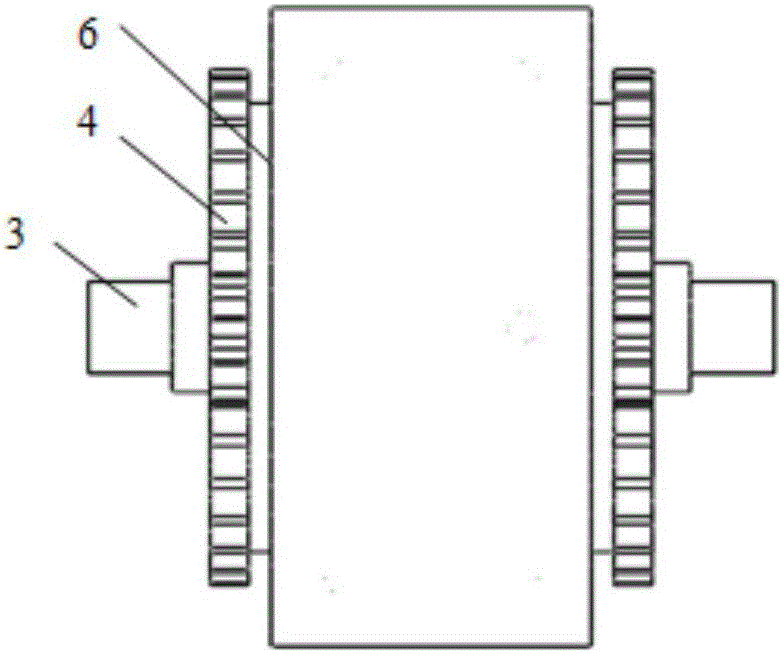

[0020] exist figure 1 Among them, the synchronization rod 2 and the axle probe frame 3 are installed on the bracket 1, two water injection holes 7 are opened on the gear 4 and the wheel plate 6, and the dry coupling layer 5 is glued on the wheel plate 6. Before testing, water is filled into the airtight space formed by the wheel plate 6 and the dry coupling layer 5 through the water injection hole 7 . Gear two 4 are installed on the wheel plate 6, fixed by four screws 8.

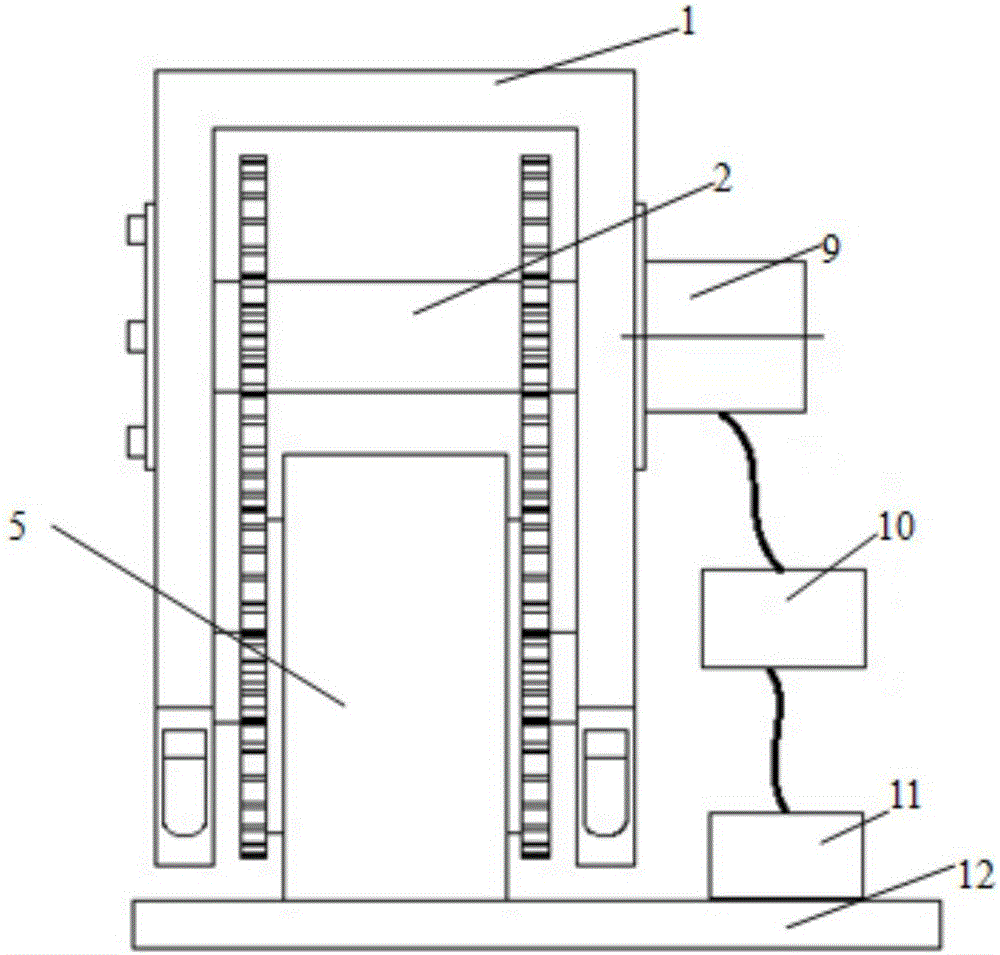

[0021] exist figure 2 Among them, the gear two 4 and the gear one 14 on the synchronous rod 2 mesh with each other, and a motor 9 is installed at one end of the synchronous rod 2 to drive it to rotate, and the relative motion speed of the metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com