Cable wear tractioned cavity cleaning device

A cavity-cleaning and cable-clearing technology, which is applied in the direction of cable installation, cable installation devices, and cable laying equipment, can solve the problems of large pulling resistance, dead angles, and low work efficiency, so as to achieve smooth and stable operation, save construction costs, clean up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

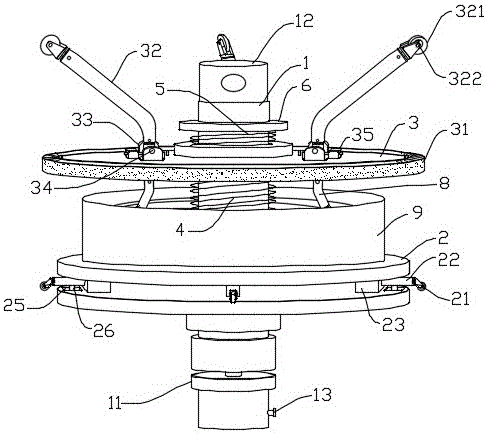

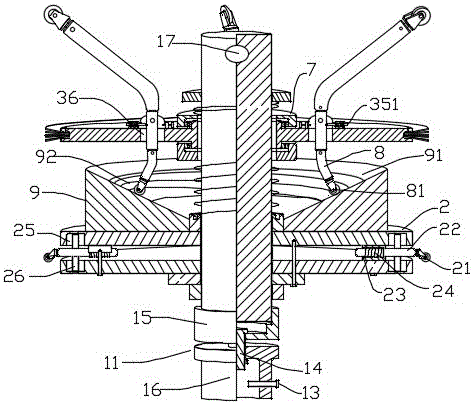

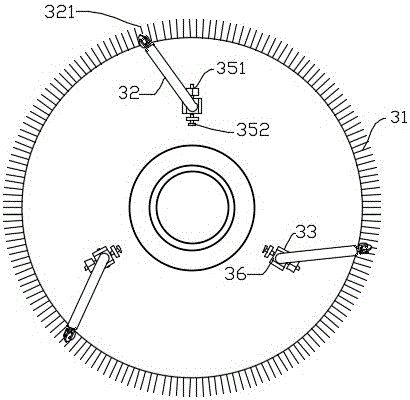

[0021] refer to figure 1 and figure 2 , the cable pipe traction cleaning device includes a main shaft made of a hard metal material with a diameter of 3 cm and a length of 20 cm. A cable connector 11 is provided at one end of the main shaft 1. The cable connector 11 shown in the figure includes a fixing bolt Head 15 and movable cap body 16; Fixed bolt head 15 plays a role of connection and fixation, and it is fastened and connected with main shaft 1 end by thread; Movable cap body 16 is movably connected with fixed bolt head 15 by connecting pin 14, and movable cap body 16 can Flexible rotation. The outer end of the movable cap body 16 is provided with a cable socket, and the movable cap body 16 is provided with a fixing bolt 13 for fixing the inserted cable. The other end of the main shaft 1 is a traction joint 12 , and a traction joint hole 17 is arranged on the traction joint 12 . The main shaft 1 is provided with a support plate 2 close to the cable connector 11 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com