Corner connector for connecting at least two frame profiles of a frame which are arranged perpendicularly relative each other

A technology of corner connectors, perpendicular to each other, applied in the frame of the substation/switchgear, connecting members, connecting rods, etc., can solve problems such as access, and achieve the effect of low manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

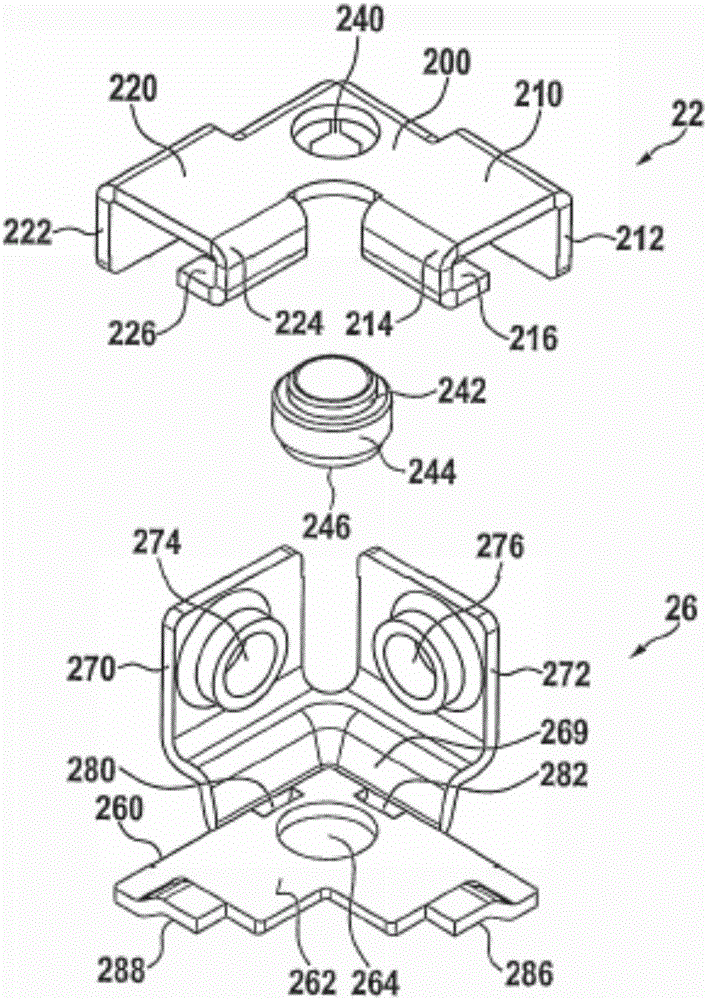

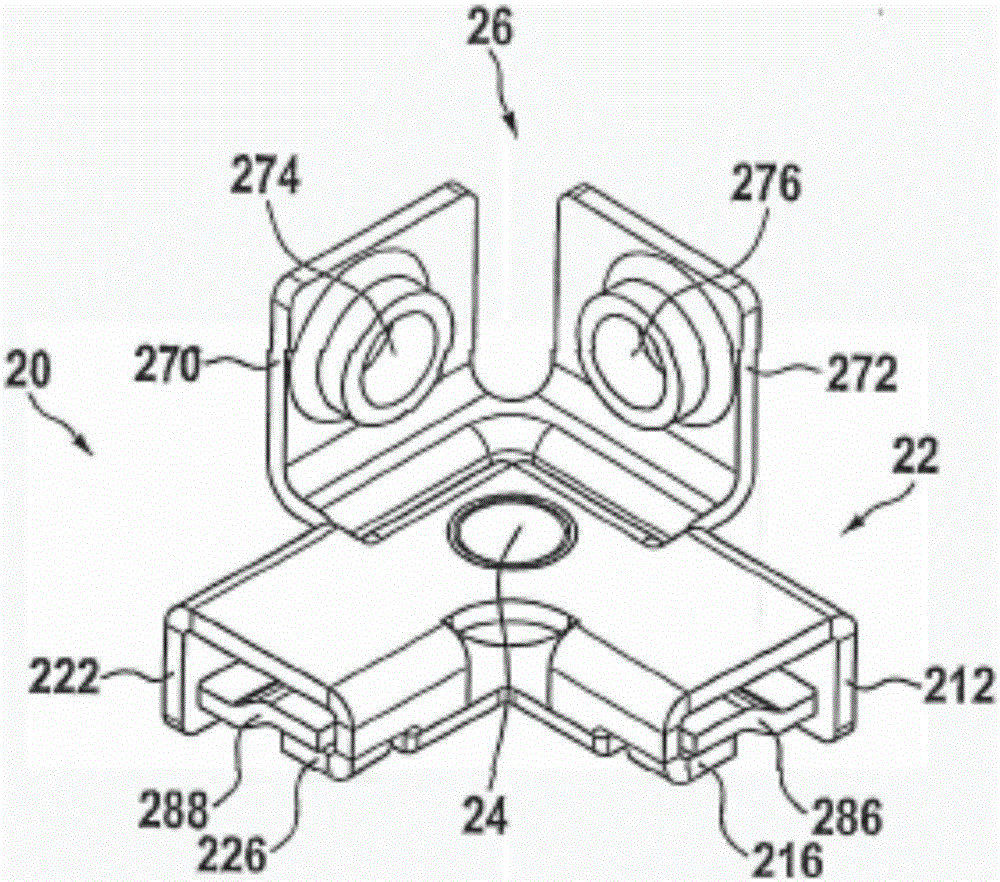

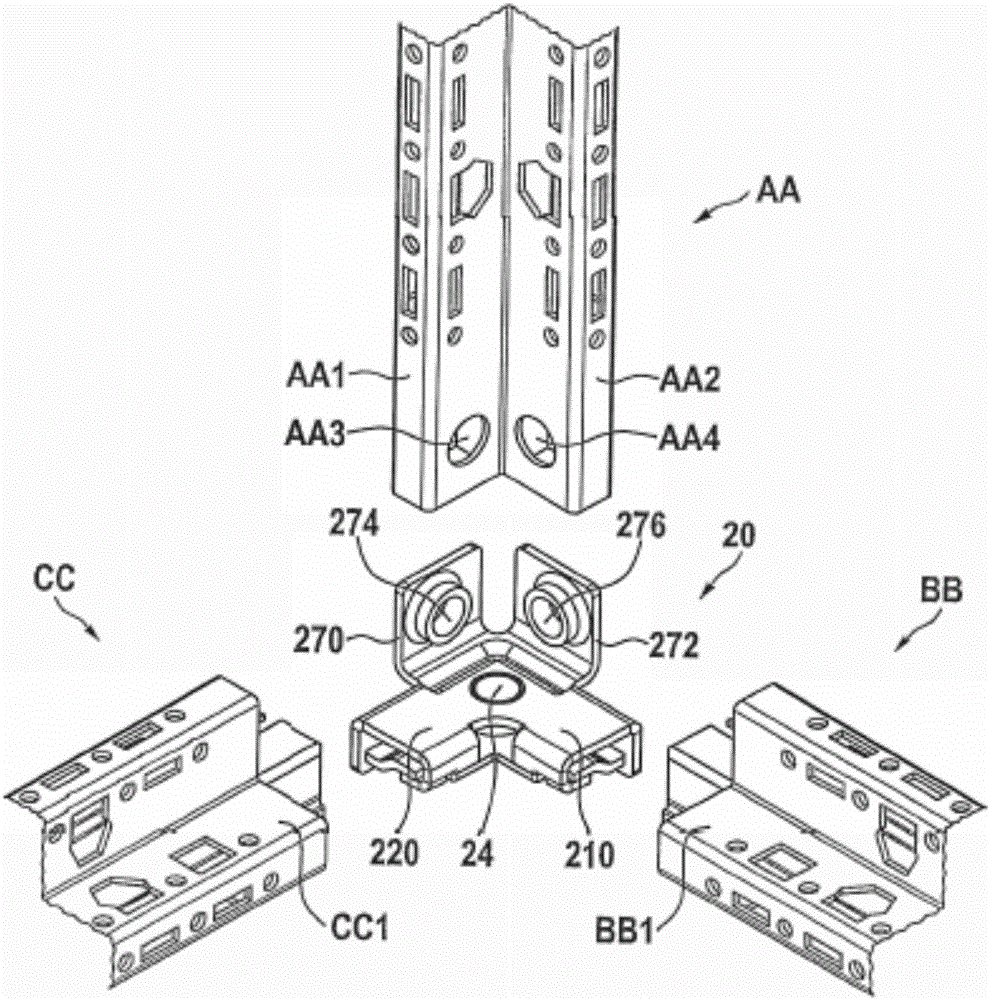

[0021] figure 1 The corner connector 20 according to the invention is shown in an exploded view. The corner connector 20 is composed of a first piece 22 , a threaded sleeve 24 and a second piece 26 . Starting from the central part 200 , the plate part 22 has two humerus parts 210 , 220 , established at an angle of 90°, the flat upper surfaces of which are aligned with the central part 200 . The respective humerus 210 , 220 is bent, wherein the bending regions 212 , 222 of the respective humerus 210 , 220 pointing away from each other protrude beyond the central part 200 at an angle of approximately 90°. The bent areas 214, 224 of the humerus 210, 220 pointing toward each other likewise protrude beyond the central part 200 at an angle of 90°, but are then bent again to form webs 216, 226, wherein the respective webs 216, 226 point oppositely. The bending areas 212, 222 are placed. In the central piece 200 there is furthermore a receiving opening 240 into which the threaded s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap