Driving mechanism of automatic soap dispenser

A driving mechanism, soap dispenser technology, applied in the direction of electromechanical devices, electric components, control mechanical energy, etc., can solve the problems of poor reliability, easy damage, complex structure, etc., to achieve the effect of increasing torque, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing and example.

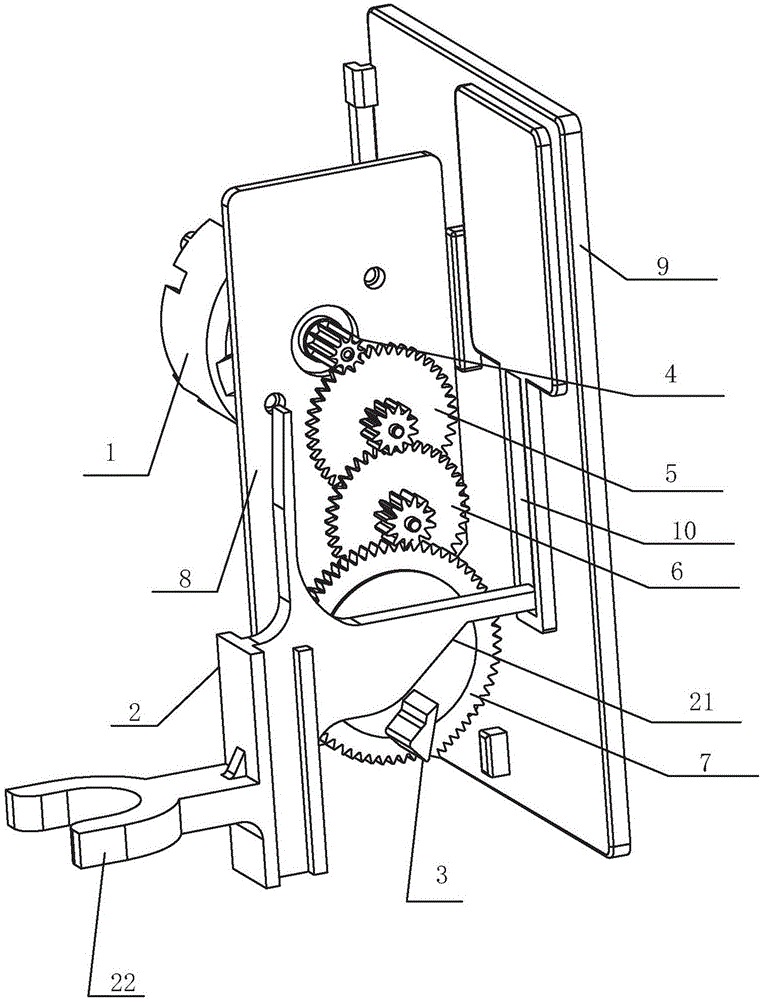

[0015] refer to figure 1 , the drive mechanism of a kind of automatic soap dispenser of the present invention, comprises motor 1, gear set, sliding support 2, control circuit, and described control circuit is connected motor to output control signal to it, and the rotating shaft of described motor 1 and The gear set is connected, and the gear set includes a plurality of transmission gears connected sequentially from top to bottom, wherein a transmission shaft 3 is arranged at the non-center of the bottom gear surface, and the transmission shaft 3 is connected with the sliding support 2 to drive The sliding support 2 moves up and down, and the sliding support 2 is fixedly connected with the pump head of the liquid outlet pump.

[0016] Described gear group comprises gear post 4, duplex gear A 5, duplex gear B 6, bull gear 7, and described gear post 4 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com