A strontium apatite bone cement and its preparation method

A technology of strontium apatite and bone cement, which is applied in the field of strontium apatite bone cement and its preparation, can solve the problems of unreported, high product crystallinity, no control and optimization of particle size, etc., and achieve easy mixing and uniform increase of specific surface area , the effect of reducing hair volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Bone cement was prepared according to the following steps:

[0037] (1) Preparation of strontium apatite

[0038] First prepare a mixed solution A of strontium nitrate and calcium nitrate of 0.05-0.5 mol / L, and prepare diammonium hydrogen phosphate solution B with the same concentration as A; in solution A, the ratio of strontium to the total molar amount of strontium and calcium is not less than 0.15, preferably strontium The ratio to the total molar amount of strontium calcium is not less than 0.4;

[0039] In a water solution at 90-95°C, according to the volume ratio A:B is 1.67, add B to A, stir and mix to obtain a cloudy precipitate suspension; add nitric acid to adjust the pH value to 2, the solution becomes clear, and stir for 0.5-1h After adding ammonia water, a white precipitate gradually precipitates out, adjust the pH value to 9-11, and react for 2 hours;

[0040] Finally, react the white precipitate in a gaseous environment with a temperature of 100-300° C...

Embodiment 1

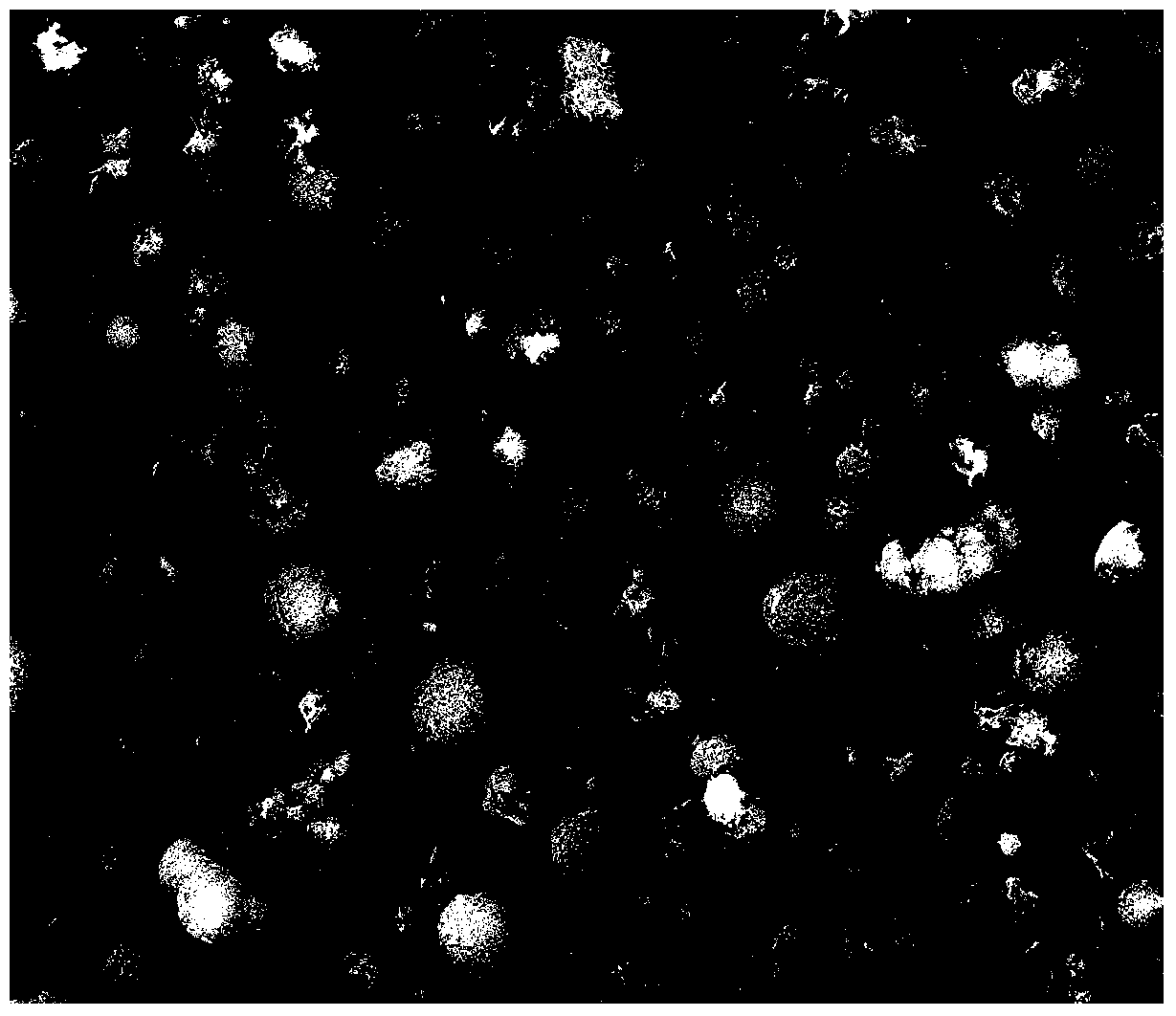

[0045] The particle size distribution range of PMMA is 53-100 μm, that of strontium apatite is 5-37 μm, and that of barium sulfate is 5-10 μm.

[0046] (1) Preparation of strontium apatite

[0047] First configure 200mL×0.05mol / L strontium nitrate and calcium nitrate mixed solution A, configure 100mL×0.05mol / L diammonium hydrogen phosphate solution B; in solution A, the ratio of strontium to the total molar amount of strontium calcium is 0.4;

[0048] In a water solution at 95°C, according to the volume ratio A:B is 1.67, add 100mL B into 167mLA, stir and mix to obtain a cloudy precipitate suspension; add nitric acid to adjust the pH value to 2, the solution becomes clear, stir for 0.5h and then Add ammonia water, a white precipitate precipitates out, adjust the pH value to 10, and react for 2 hours;

[0049] Finally, react in a gas environment with a temperature of 250°C and a pressure of 1.5 MPa for 24 hours, dry, and sieve to obtain strontium apatite;

[0050] (2) Prepara...

Embodiment 2

[0057] PMMA particle size distribution range is selected as 10-53 μm, strontium apatite is 2.5-20 μm, barium sulfate is 0.2-8 μm

[0058] (1) Preparation of strontium apatite

[0059] First configure 200mL×0.5mol / L strontium nitrate and calcium nitrate mixed solution A, configure 100mL×0.5mol / L; in solution A, the ratio of strontium to the total molar amount of strontium calcium is 0.15;

[0060] In water solution at 90°C, according to the volume ratio A:B is 1.67, add 100mL B into 167mLA, stir and mix to get a cloudy precipitate suspension; add nitric acid to adjust the pH value to 2, the solution becomes clear, stir for 1 hour before adding Ammonia, a white precipitate gradually precipitated, adjust the pH value to 11, and react for 2 hours;

[0061] Finally, react in a gas environment with a temperature of 300°C and a pressure of 2 MPa for 3 hours, dry, and sieve to obtain strontium apatite;

[0062] (2) Preparation of bone cement

[0063] Weigh 40% PMMA, 50% strontium a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com