Method and apparatus for forming heat-treated material

A heat and base technology, applied in electric heating devices, heat treatment furnaces, heat treatment equipment, etc., can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Reference throughout this specification to "one embodiment," "an embodiment," or similar language means that a particular feature, structure, or characteristic described in connection with the embodiment is included in at least one embodiment of the present disclosure. Occurrences of the phrases "in one embodiment," "in an embodiment," and similar language throughout this specification may, but not necessarily all, refer to the same embodiment . Similarly, use of the term "implementing" means an implementation having a particular feature, structure, or characteristic described in connection with one or more embodiments of the present disclosure, but, in the absence of a related expression indicating otherwise, an implementation may Associated with one or more implementations.

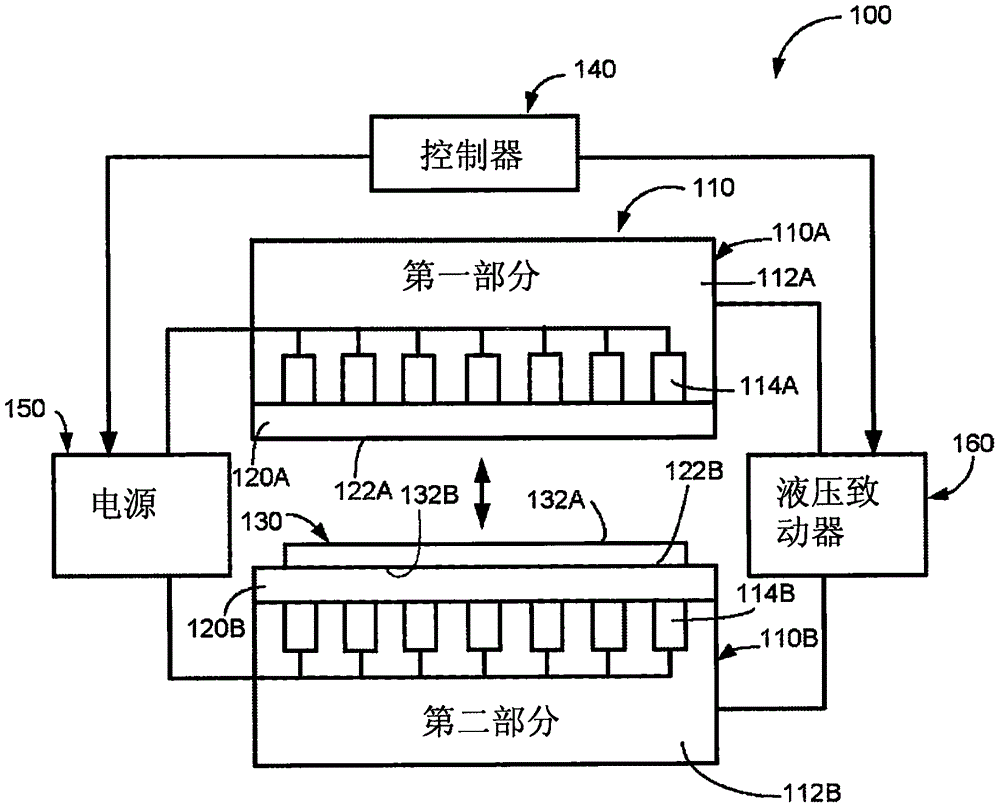

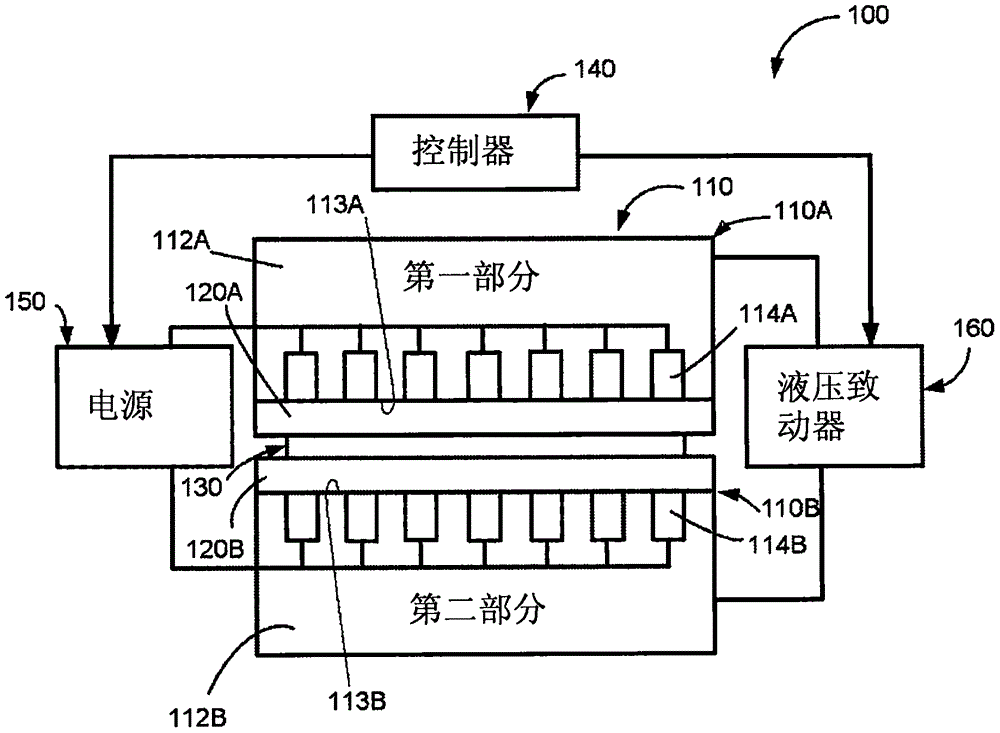

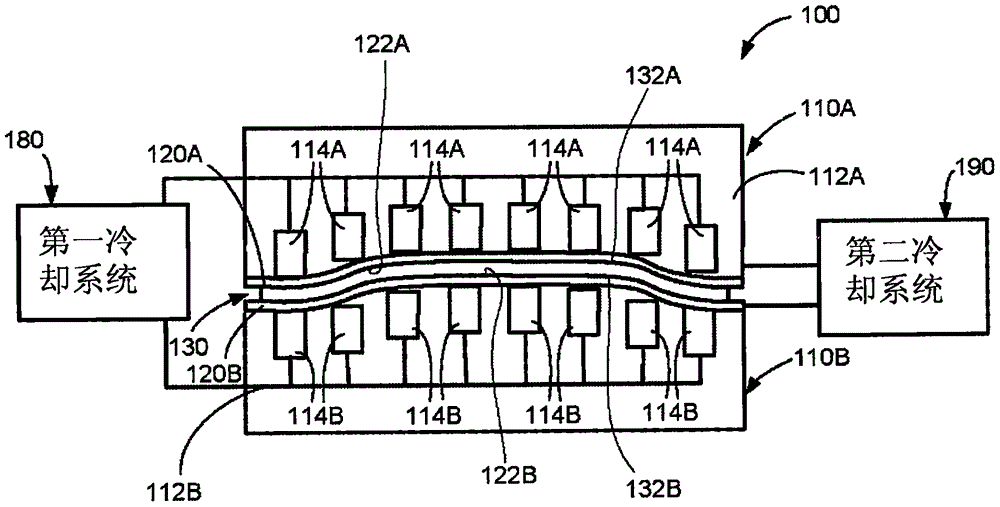

[0027] refer to figure 1 And according to one embodiment, a system 100 for shaping a heat-treated material 130 is shown. System 100 includes device 110 operably coupled to controller 140 , pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com