A marine low-speed engine valve plate bottom and its welding process

A welding process and low-speed machine technology, applied in welding equipment, lift valves, valve devices, etc., can solve problems such as unsatisfactory surfacing and poor alloy fusion, and achieve high welding efficiency, stable quality, and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Firstly, the diesel engine valve blank of SNCrW and the welding wire of solid-solution-strengthened nickel-based deformed superalloy material are selected. Among them, the composition of the center hole of the diesel engine valve disc bottom is: C: 0.25%, Si: 0.90%, Mn: 0.90%, P≤0.04%, S≤0.03%, Ni: 9.0%, Cr: 18.0%, W : 1.8%, Nb≤0.1%, B: 0.001%, N: 0.04%, and the balance is Fe; the welding wire is Inconel625 material with molybdenum and niobium as the main strengthening elements, and its diameter is 1.0mm. And choose the mixed gas of Ar / 15He as the welding shielding gas, the mixing ratio of the shielding gas is 85% Ar, 15% He.

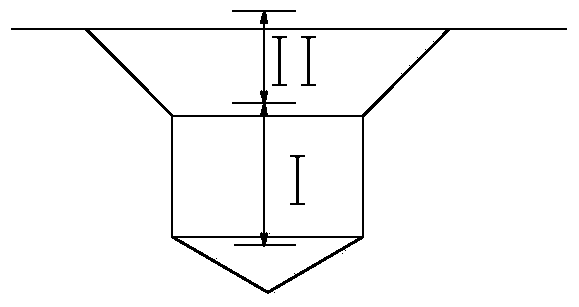

[0021] According to the shape of the center hole at the bottom of the valve disc, it is divided into a straight hole section and an inclined hole section. like figure 1 As shown, in the straight hole section, d1=11mm, h1=7mm, in the inclined hole section, d2=21mm, h2=12mm.

[0022] Secondly, because in a high-temperature environment, nickel is...

Embodiment 2

[0030] Firstly, the diesel engine valve blank of SNCrW and the welding wire of solid-solution-strengthened nickel-based deformed superalloy material are selected. Among them, the composition of the center hole of the diesel engine valve plate bottom is: C: 0.28%, Si: 0.95%, Mn: 0.95%, P≤0.04%, S≤0.03%, Ni: 10.0%, Cr: 19.0%, W : 2.0%, Nb≤0.1%, B: 0.0015%, N: 0.06%, and the balance is Fe; the welding wire is Inconel625 material with molybdenum and niobium as the main strengthening elements, its diameter is 1.1mm, and Ar / The mixed gas of 15He is used as the welding shielding gas, and the mixing ratio of the shielding gas is 85% Ar, 15% He.

[0031] According to the shape of the center hole at the bottom of the valve disc, it is divided into a straight hole section and an inclined hole section. like figure 1 As shown, in the straight hole section, d1=11mm, h1=7mm, in the inclined hole section, d2=21mm, h2=12mm.

[0032]Secondly, because in a high-temperature environment, nicke...

Embodiment 3

[0040] Firstly, the diesel engine valve blank of SNCrW and the welding wire of solid-solution-strengthened nickel-based deformed superalloy material are selected. Among them, the composition of the center hole of the diesel engine valve plate bottom is: C: 0.27%, Si: 0.95%, Mn: 0.95%, P≤0.04%, S≤0.03%, Ni: 9.5%, Cr: 20.0%, W : 2.1%, Nb≤0.1%, B: 0.002%, N: 0.075%, and the balance is Fe; the welding wire is Inconel625 material with molybdenum and niobium as the main strengthening elements, its diameter is 1.2mm, and Ar / The mixed gas of 15He is used as the welding shielding gas, and the mixing ratio of the shielding gas is 85% Ar, 15% He.

[0041] According to the shape of the center hole at the bottom of the valve disc, it is divided into a straight hole section and an inclined hole section. like figure 1 As shown, in the straight hole section, d1=11mm, h1=7mm, in the inclined hole section, d2=21mm, h2=12mm.

[0042] Secondly, because in a high-temperature environment, nicke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com