Device for automatically detecting starting point and ending point of lap seam welding of metal part

A technology of automatic detection and metal parts, applied in the direction of welding power supply, welding equipment, roller electrode welding, etc., can solve the problems of shortening welding time, long welding process time, and inability to ensure full welding, etc., to shorten the welding process time and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the specific drawings and embodiments.

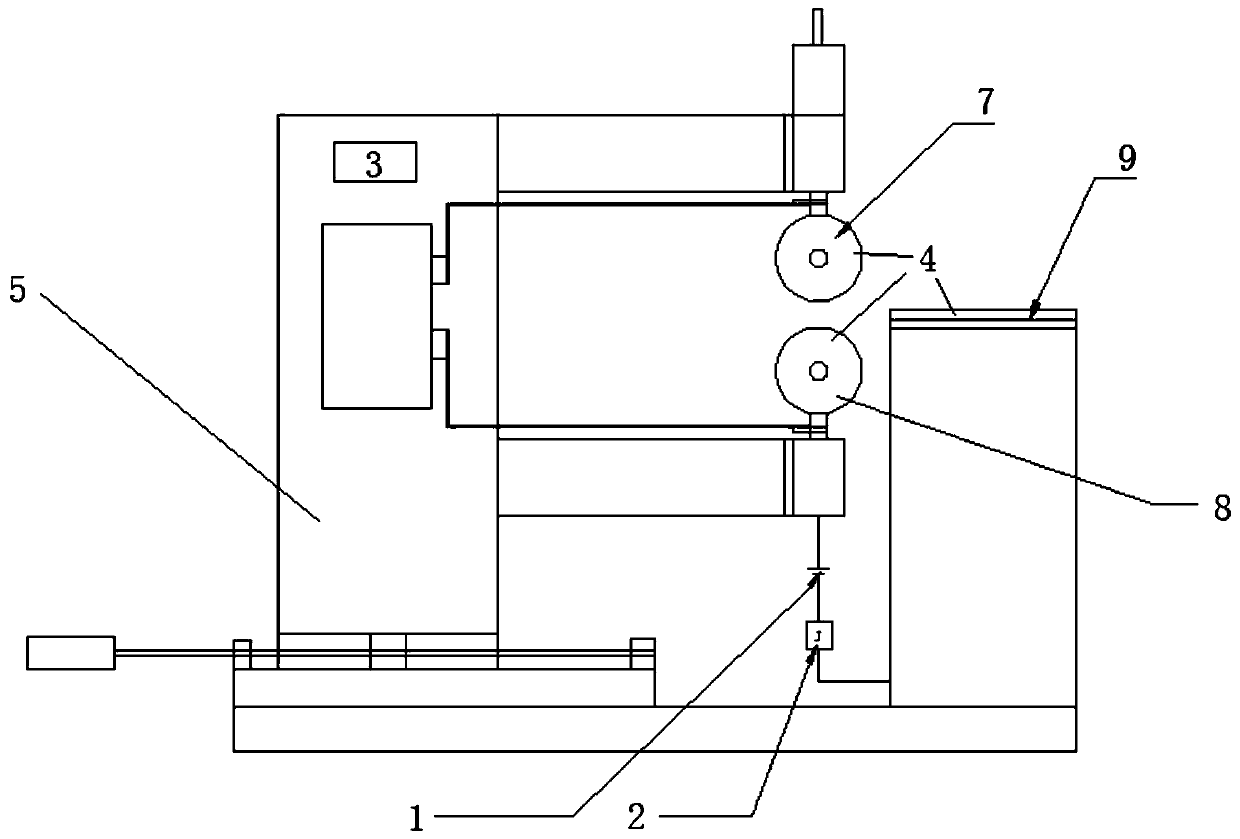

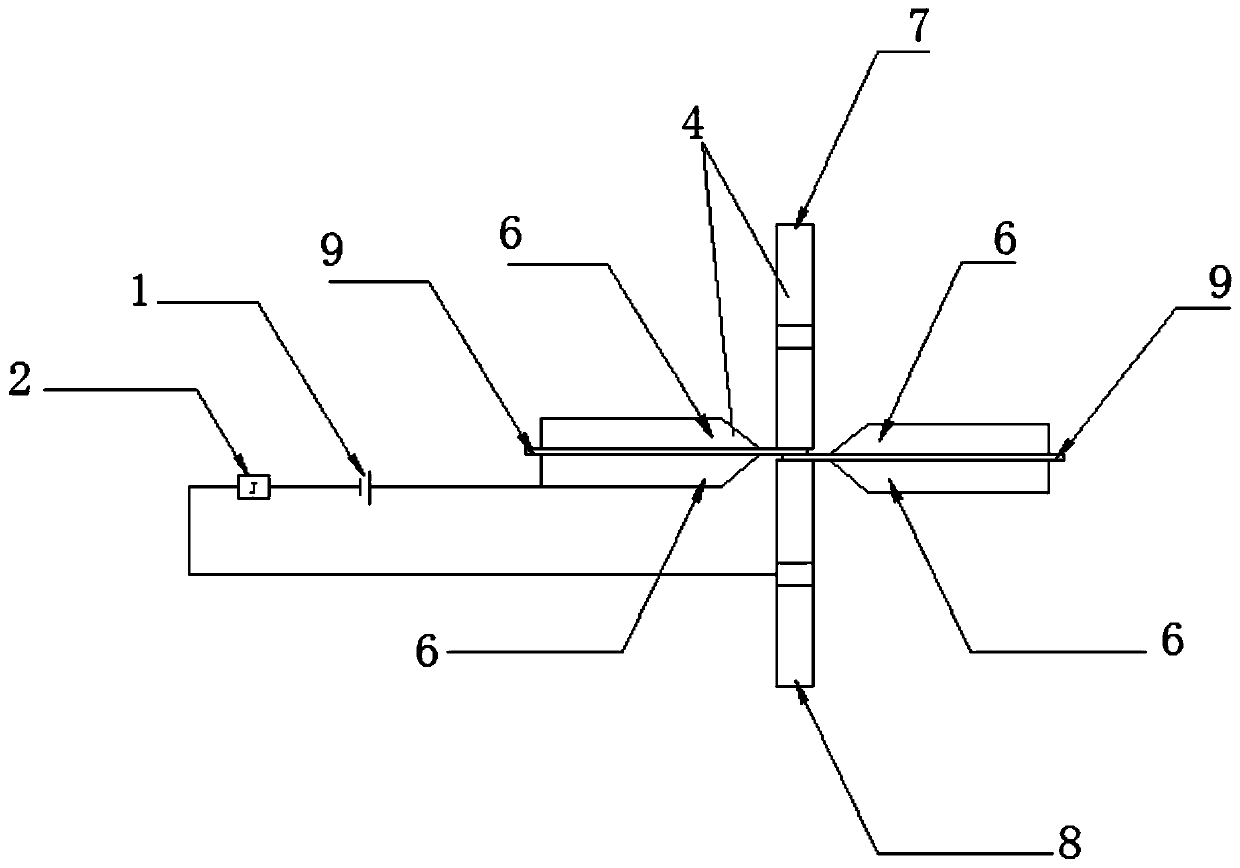

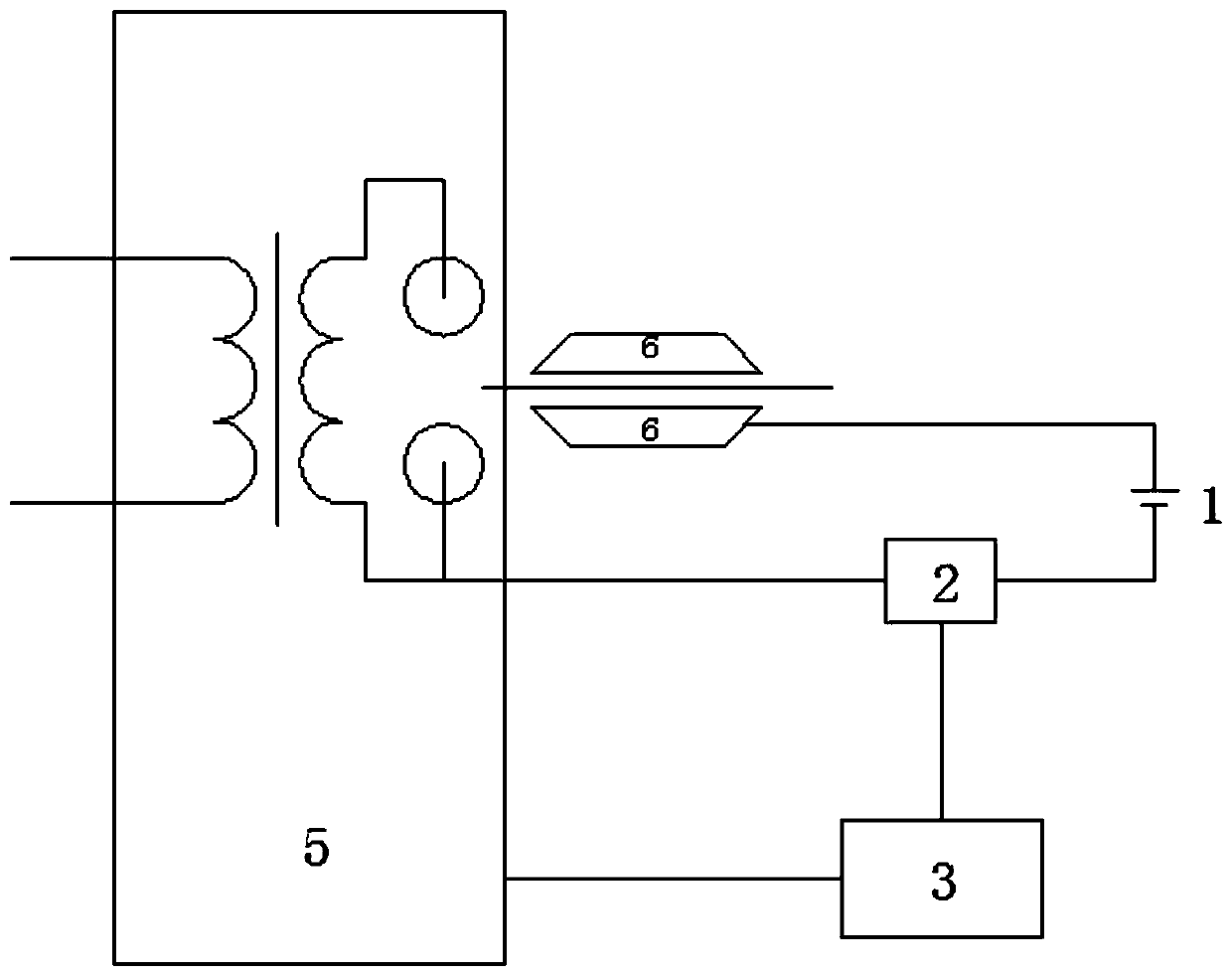

[0019] like figure 1 , figure 2 , image 3 As shown, the embodiment of the present invention proposes a device for automatically detecting the starting point and end point of lap welding welding of metal parts, including: an auxiliary power supply 1, a relay 2, and a PLC controller 3; wherein the auxiliary power supply 1, the relay 2, the welding part 4. The workpiece 9 forms a small loop, the relay 2, the PLC controller 3, and the welding machine main body 5 form a large loop, and the PLC controller 3 can control the welding machine main body 5 to perform actions.

[0020] The PLC controller 3 can collect the signal that the relay 2 is closed or disconnected, so as to control the main body 5 of the welding machine to walk and perform welding.

[0021] Auxiliary power supply 1 is a regulated DC power supply that can be 12V, 24V, and 36V, with low power co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com