Biomass sawing device

A biomass and sawing technology, used in circular saws, grain processing, sawing equipment, etc., can solve the problems of increased production costs, low crushing efficiency, and high requirements for drying biomass raw materials, and achieves high sawing speed, High crushing efficiency and the effect of reducing drying costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

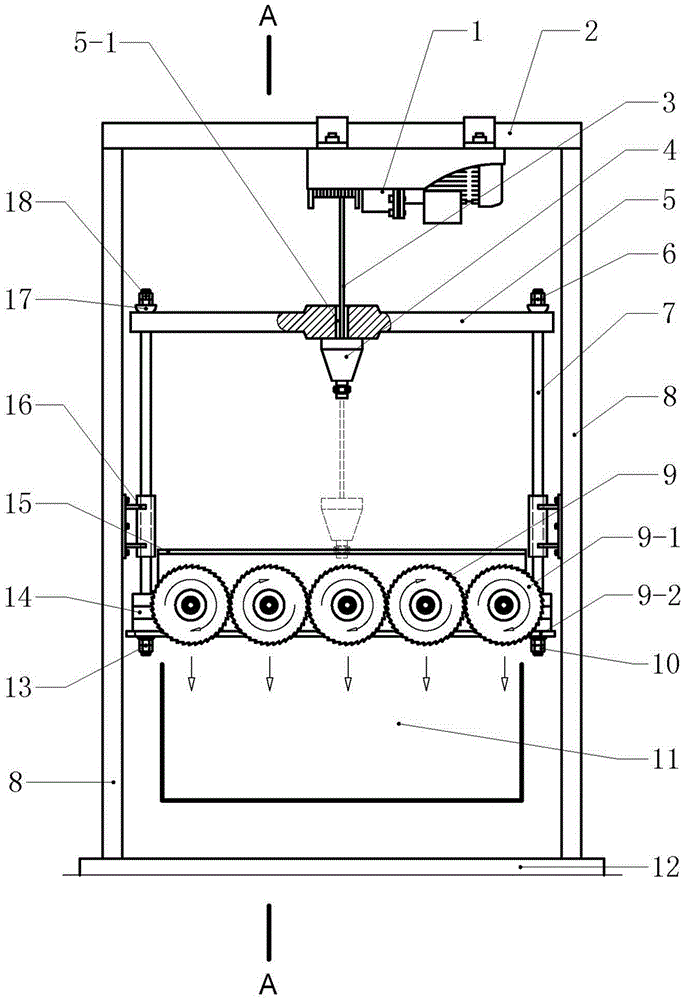

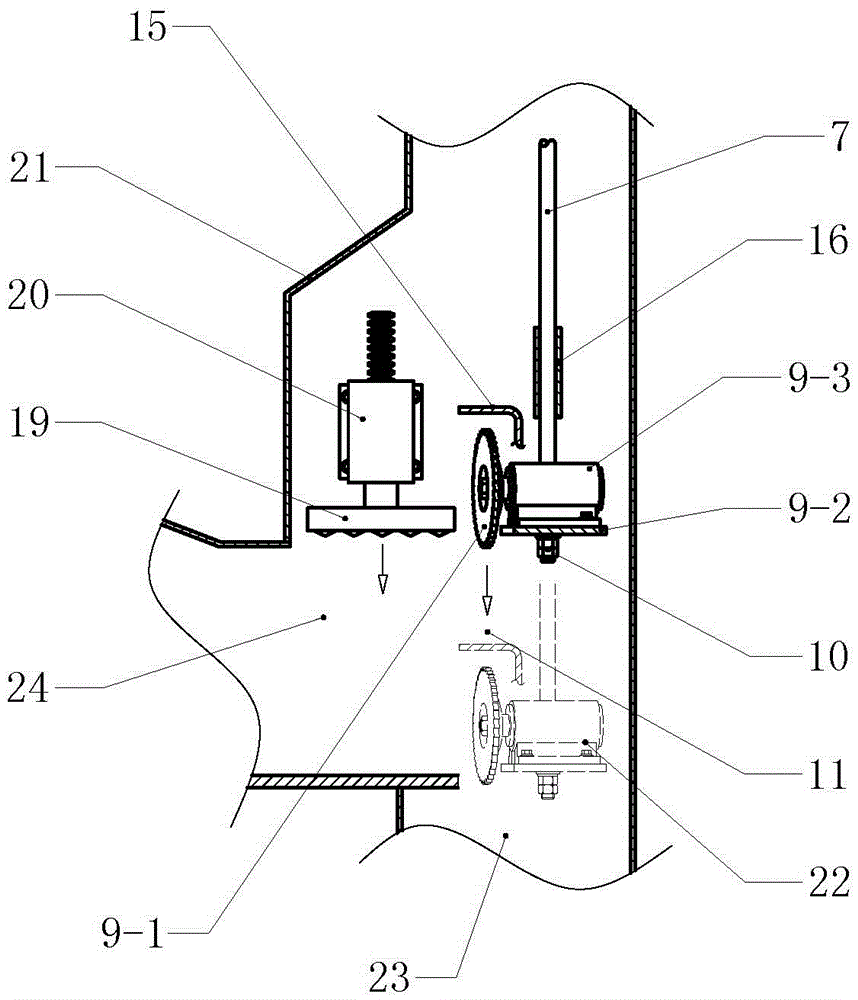

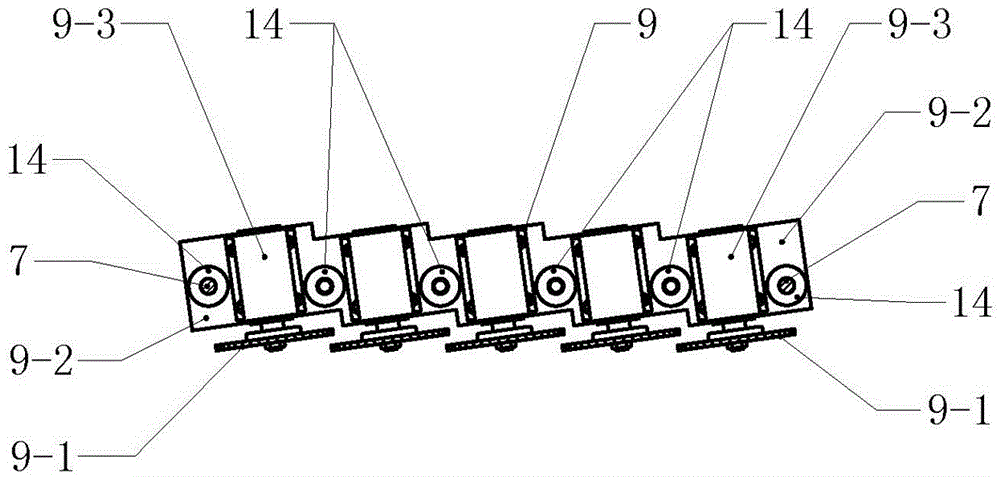

[0015] Example Figure 1-3 In the illustrated embodiment, the biomass sawing device is mainly composed of an electric hoist 1, a frame 8, a movable saw row assembly 9, a tubular guide 16, a lifting rod 7, a beam 5 and an enclosure 21, and the electric hoist 1 and The frame 8 is arranged in the enclosure 21, and the electric hoist 1 is installed on the top beam of the frame 8. The movable saw blade assembly 9 is composed of a movable chassis 9-2, a small high-speed motor and multiple circular saw blades. Small high-speed motors are arranged on the movable chassis 9-2, and circular saw blades are installed on the shaft of each small high-speed motor. The circular saw blades are arranged horizontally in a straight line, and the sawing direction of the circular saw blades is vertically downward. There is a horizontal angle between the axial normal of the small high-speed motor and the circular saw blade on the saw blade assembly 9 and the vertical line of the front plane of the dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com