Automobile rear protective wire harness

A technology for automobiles and wiring harnesses, applied in vehicle components, circuits or fluid pipelines, transportation and packaging, etc., can solve the problems of unstable signal transmission, single function, hidden safety hazards, etc., to improve reliability and anti-interference ability, structure The effect of simple differentiation and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following describes the implementation of the present invention in detail with reference to the drawings, but it does not constitute a limitation to the present invention, and is only an example. At the same time, through the description, the advantages of the present invention will become clearer and easier to understand.

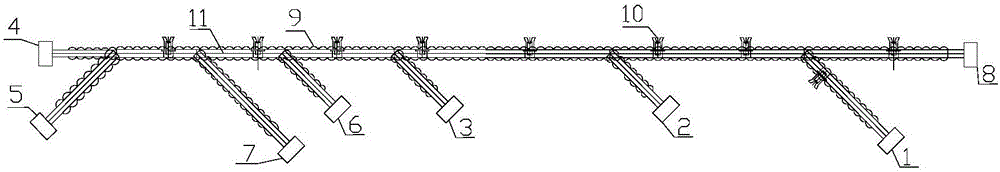

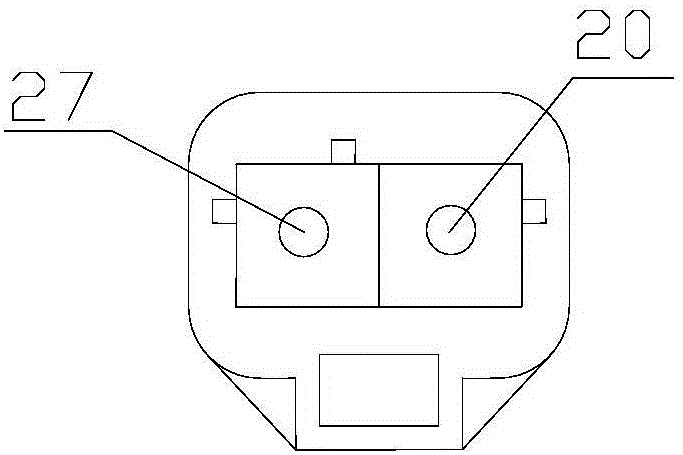

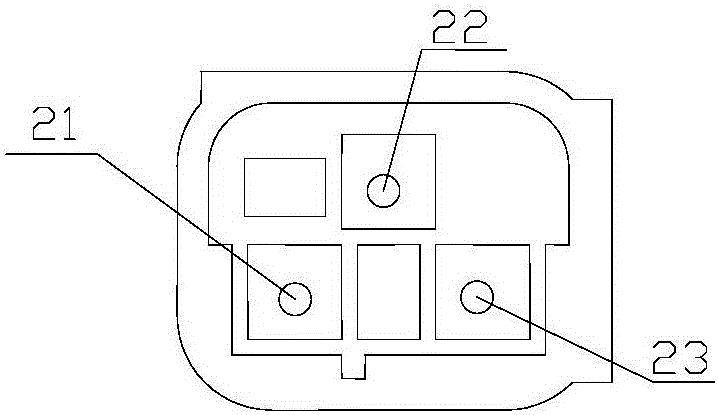

[0023] Such as figure 1 As shown, an automobile rear protection wiring harness (a wiring harness installed in the rear bumper of an automobile) includes a signal transmission cable 11 and a plurality of ports, characterized in that: the signal transmission cable 11 includes a first wire 20 and a second wire 21. The third wire 22, the fourth wire 23, the fifth wire 24, the sixth wire 25, the seventh wire 26, and the eighth wire 27. The multiple ports include the reversing light docking port 1, the first distance sensor docking port 2 , The second distance sensor docking port 3, the first cockpit wiring harness docking port 4, the second cockpit wiri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com