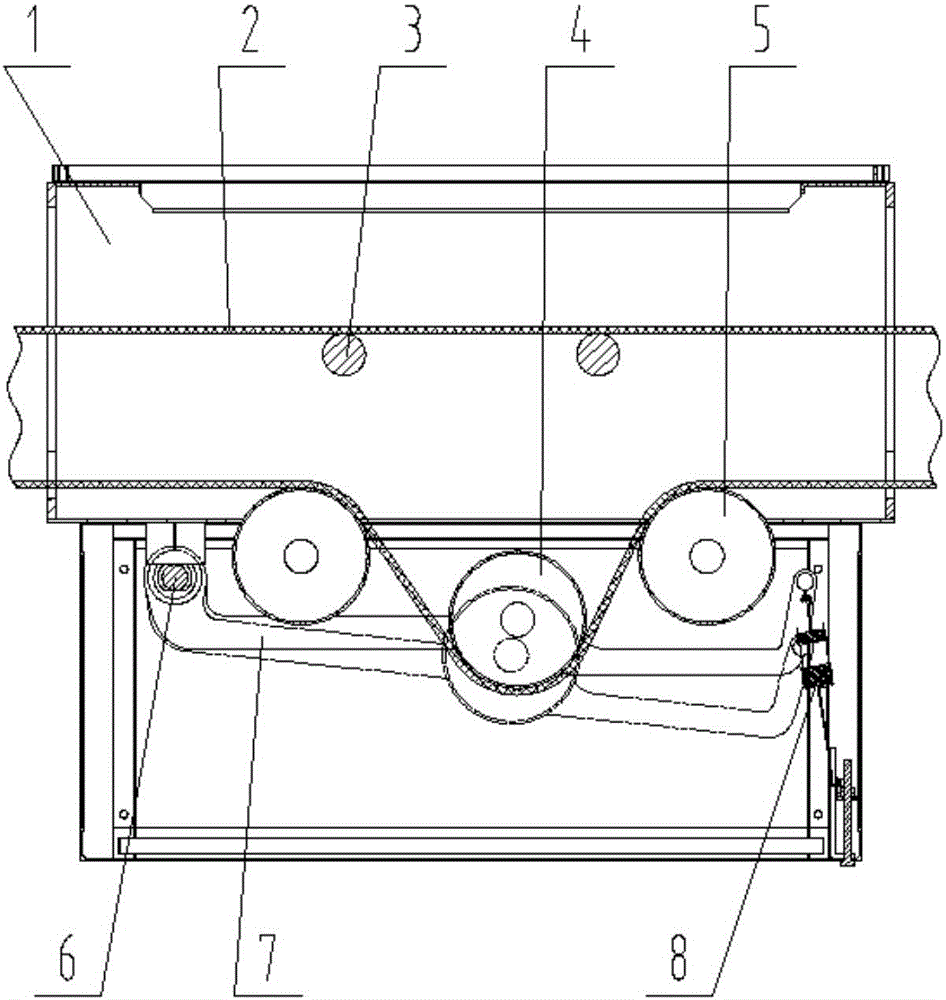

Belt conveyor and belt tensioning device thereof

A belt conveyor and tensioning device technology, applied in the direction of conveyor, transportation and packaging, can solve the problems of heavy weight, inconvenient transportation and high cost, and achieve the goal of reducing overall weight, improving convenience, and increasing spring force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] As mentioned in the background art section, the current belt tensioning device is heavy, inconvenient to install and maintain, and high in cost.

[0020] Based on the above research, the embodiment of the present invention provides a belt tensioning device, which can press the tension roller on the upper part of the lower belt through the gravity and spring force of the tension roller itself, and at the same time pass through and two transition rollers The mutual cooperation can achieve the purpose of belt tensioning, so the tension can be ensured, while reducing the gravity of the tensioning roller, and increasing the spring force, thereby reducing the overall weight of the belt conveyor and improving the convenience of installation and maintenance sex.

[0021] In order to make the above objects, features and advantages of the present invention more comprehensible, the specific implementation manners of the present invention will be described in detail below in conjun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com