Speed-regulating type conveying equipment

A technology of conveying equipment and speed regulation, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of complex structure of buffer unit, inconvenient adjustment and operation, etc., and achieve the effect of convenient conveying speed, simple structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

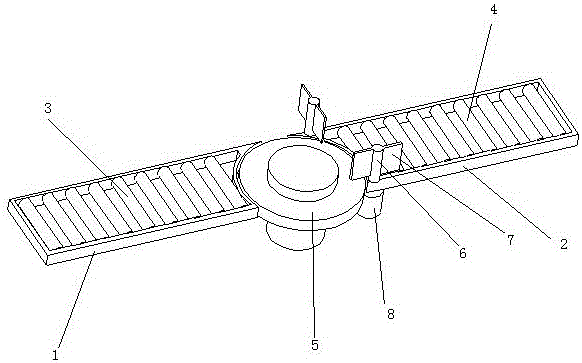

[0011] Such as figure 1 As shown, the present invention provides a speed-adjustable conveying device, comprising a first conveying frame 1, a second conveying frame 2 and a turntable 5, a plurality of first conveying rollers 3 are arranged at intervals on the first conveying frame 1, and the second conveying A plurality of second transmission rollers 4 are arranged at intervals on the frame 2, and the turntable 5 is positioned between the first transmission frame 1 and the second transmission frame 2, and the turntable 5 is driven by a first motor (not shown) to rotate, and the first transmission frame The edge facing the turntable 5 on 1 and the edge facing the turntable 5 on the second transfer frame 2 are both arc-shaped edges adapted to the edge of the turntable 5, and the first transfer frame 1, the turntable 5 and the second transfer frame 2 are jointly spliced into one overall;

[0012] The centerline of the first transmission frame 1 is on the same straight line as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com