Transmission device for glass drilling machine and glass drilling machine thereof

A conveying device and drilling machine technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of difficult to guarantee processing accuracy, prone to steering offset, short transmission distance, etc., to reduce the transmission speed, The effect of facilitating precise drilling processing and speeding up the conveying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered.

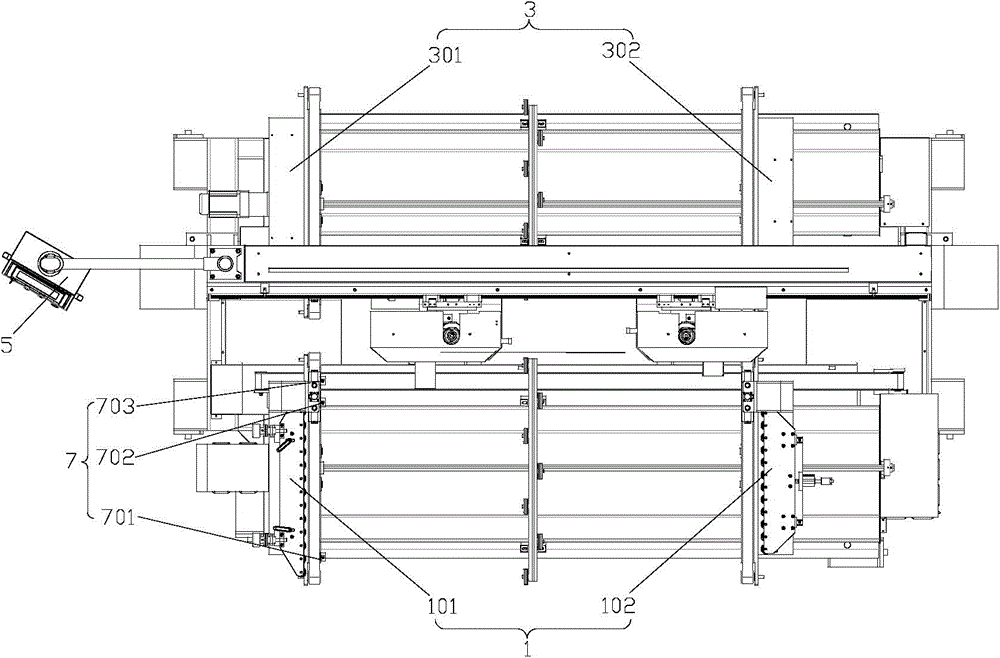

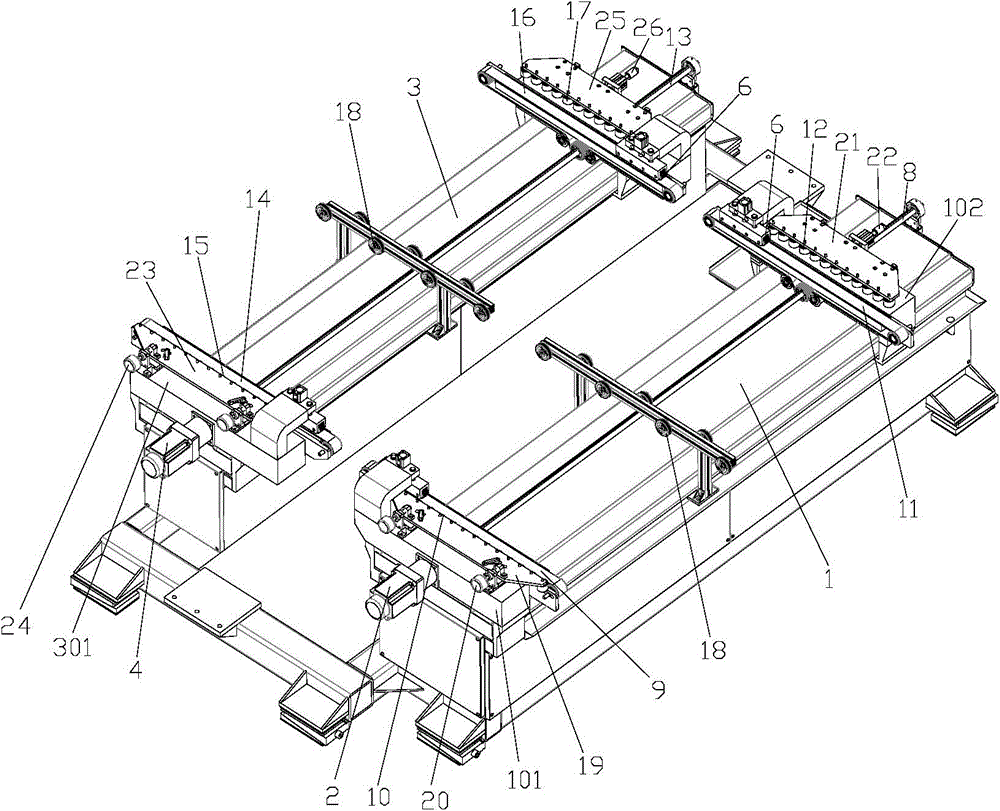

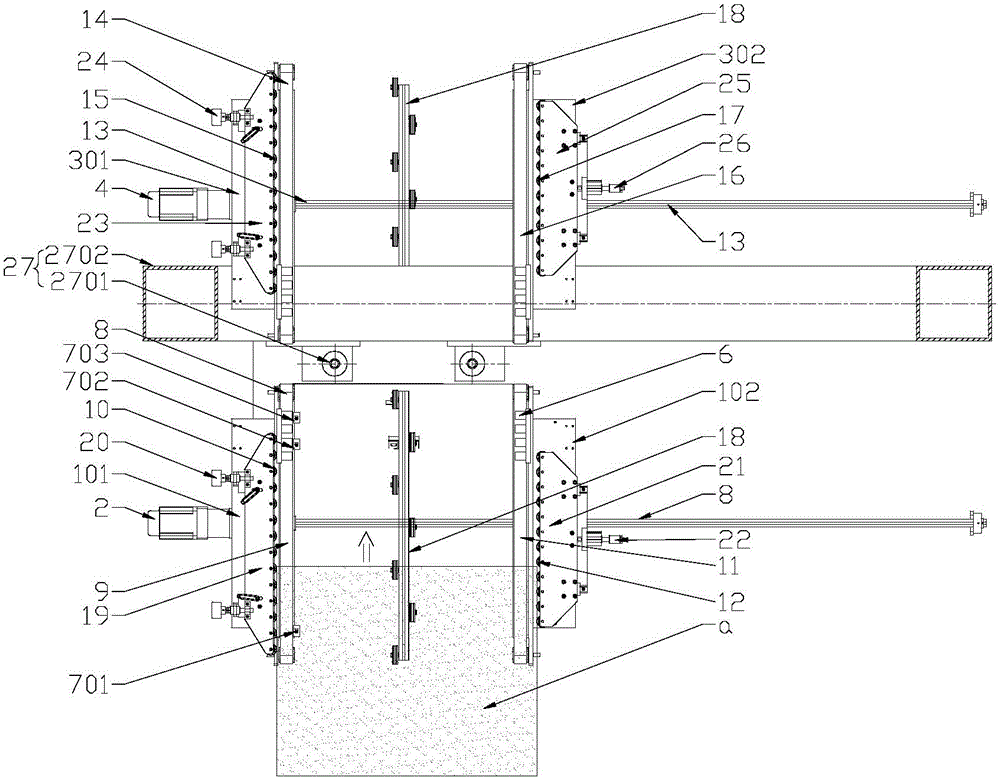

[0024] figure 1 It is one of the structural schematic diagrams of the conveyor device for the glass drilling machine in the preferred embodiment of the present invention; figure 2 It is the second structural schematic diagram of the conveyor device for the glass drilling machine in the preferred embodiment of the present invention; image 3 It is a structural schematic diagram of a glass drilling machine in a preferred embodiment of the present invention.

[0025] Such as figure 1 and figure 2As shown, the conveying device for glass drilling machine in this embodiment includes a first conveying mechanism 1 for passing the glass a to be processed into the conveying device, and a first servo motor 2 for driving the first conveying mechanism 1 for conveying , the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com