Non-bridgehead-conical-slope cast-in-situ baffle foam concrete light embankment structure and construction method

A foam concrete and cast-in-place technology, which is applied in roads, roads, buildings, etc., can solve the problems of increasing the length of bridges, occupying the space under the bridge, and many lands, so as to suppress settlement and lateral movement, increase the space under the bridge, The effect of reducing the length of the bridge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In this embodiment, the steel structure welding process, bolt connection construction process, formwork setting process, etc. will not be repeated in this embodiment, and the embodiment of the structure related to the present invention will be focused on.

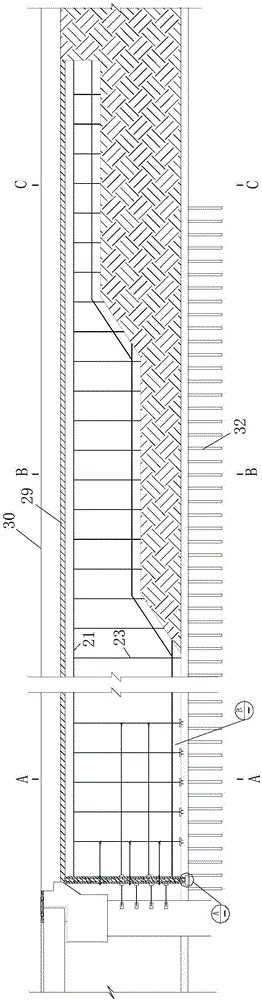

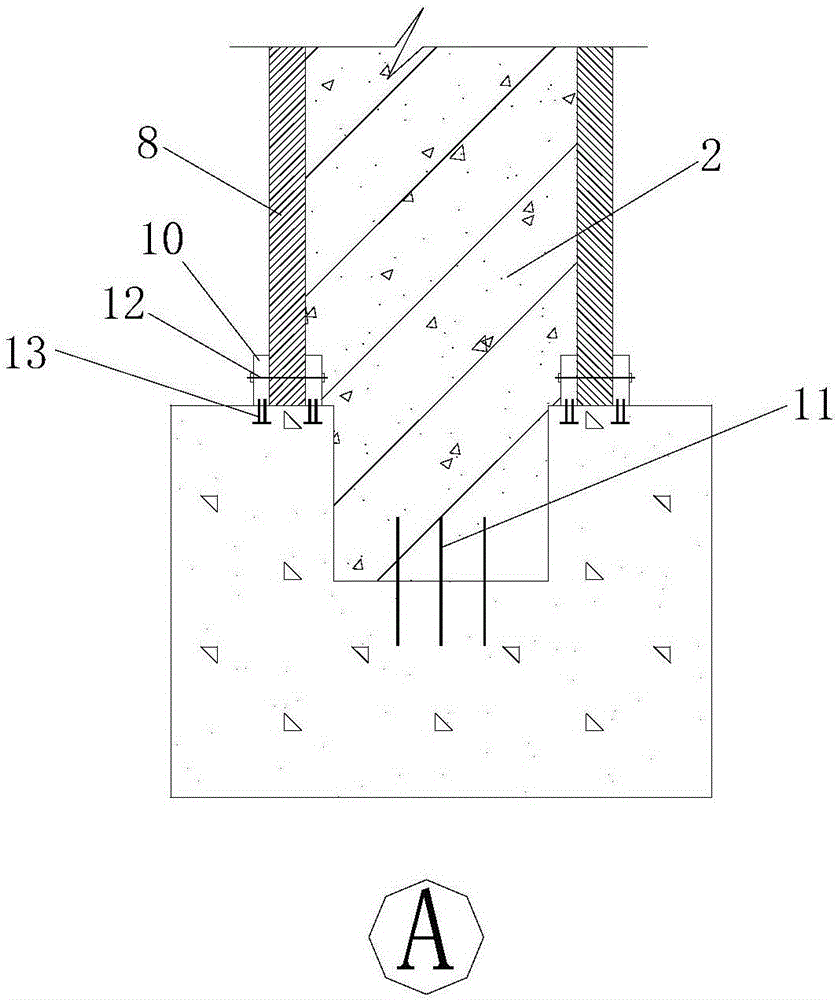

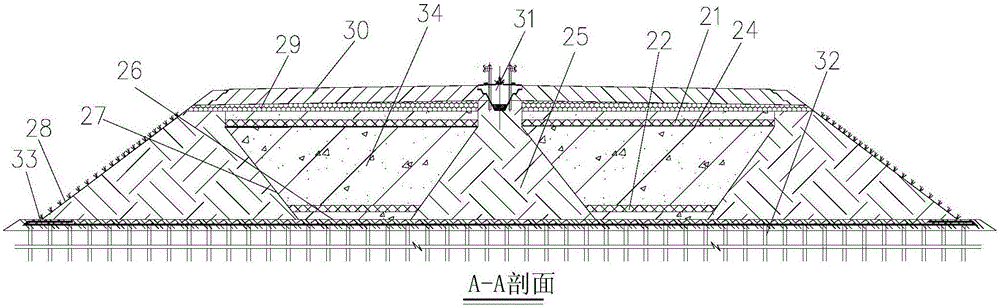

[0033] The lightweight embankment structure of cast-in-place foam concrete baffle without bridge head cone slope, including: column 1, cast-in-place concrete baffle 2, baffle foundation 3, cover beam 4, pre-embedded threaded sleeve 5, formwork brace 6, formwork guide Fixing plate 7, side formwork 8, pull screw 9, formwork fixing plate 10, baffle connecting reinforcement 11, formwork fixing screw 12, connecting key 13, fastening nut 14, transverse connecting rib 15, transverse connecting rib end plate 16 , shear reinforcement 17, vertical connection reinforcement 18, reinforcement fixing plate 19, V-shaped tie piece 20, upper reinforcement mesh 21, lower reinforcement mesh 22, vertical erection reinforcement 23, horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com