Construction method for filling foam light soil foundation pit of railroad bed in soft soil area

A technology of foam lightweight soil and railway subgrade, which is applied in filling, roads, construction, etc., can solve the problems of high project cost, long construction period, and difficulty in entering construction machinery and materials, so as to reduce project cost and reduce Effect of filling load and reducing additional stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

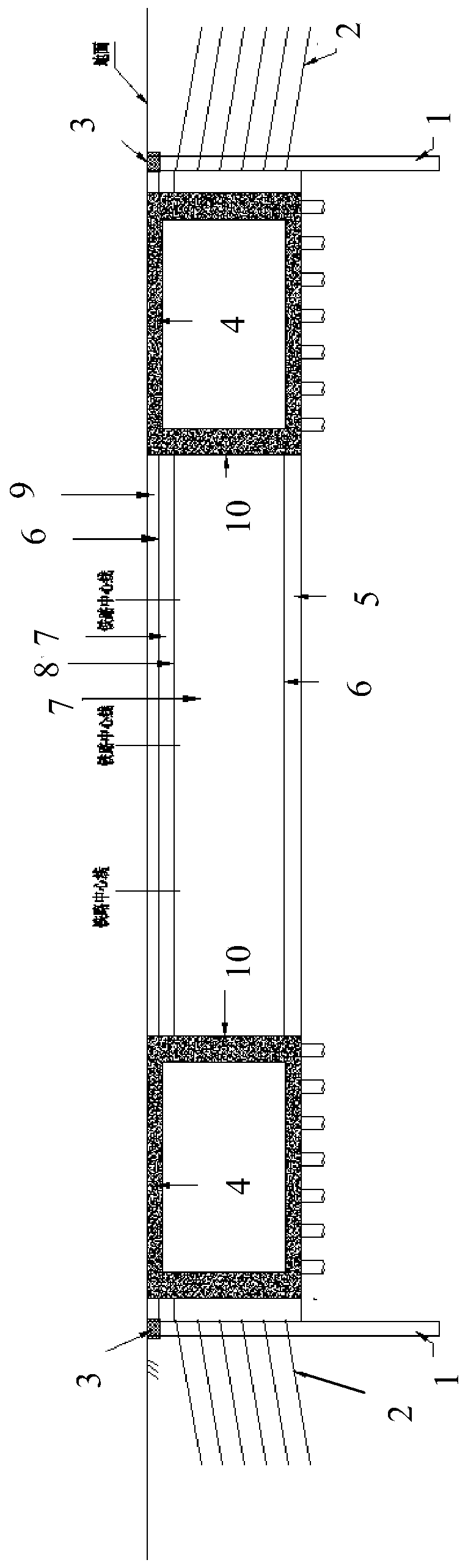

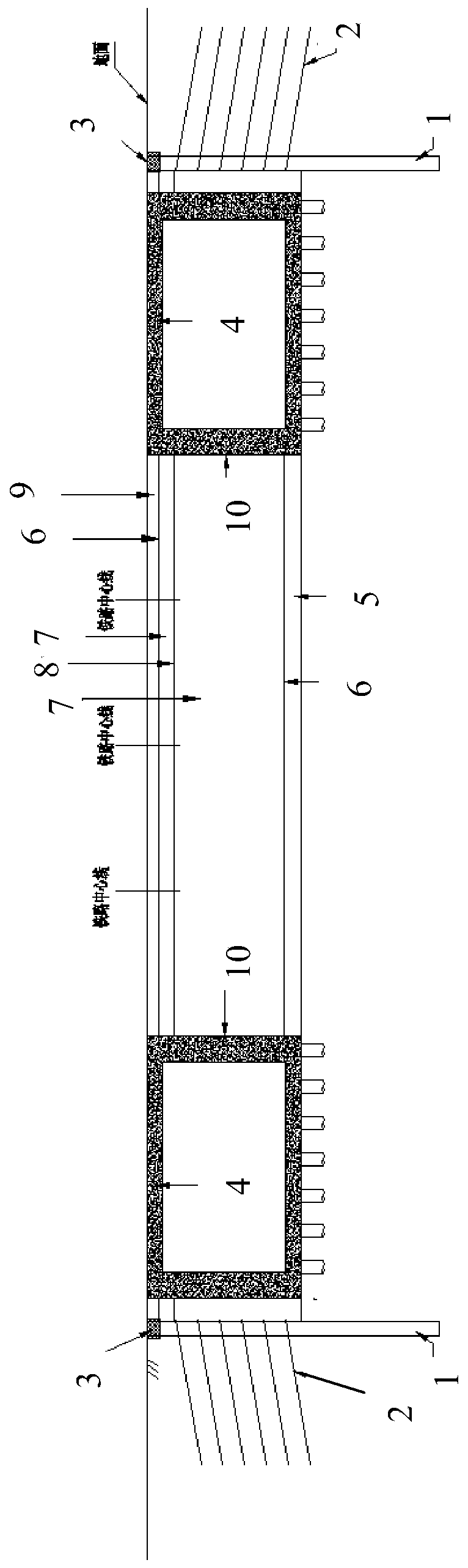

[0017] In order to better understand the purpose, structure and function of the present invention, below in conjunction with accompanying drawing, a kind of construction method of foam lightweight soil foundation pit filling of railway embankment in soft soil area of the present invention is described in further detail.

[0018] Such as figure 1 Shown, it is shown as the construction method of a kind of soft soil area railway embankment foam lightweight soil foundation pit filling of the present invention, comprises the following steps:

[0019] Step 1: Subgrade construction (leveling construction) is carried out on the original ground, and the construction is carried out under the construction conditions of four connections and one leveling.

[0020] Specifically, in step 1, the work of "four connections and one leveling" before subgrade construction on the original ground includes water supply, electricity supply, road access, telecommunications, and site leveling to prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com