Lightweight partition walls with integrated wiring

A technology of integrated wiring and lightweight partition boards, applied in the direction of walls, electrical components, building components, etc., can solve the problems of weakened strength, maintainable, replaceable, and retrofitted partitions, convenience limitations, and increased costs. Achieve the effect of improving the transformation and reuse, facilitating maintenance and repairing, and avoiding repeated wiring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

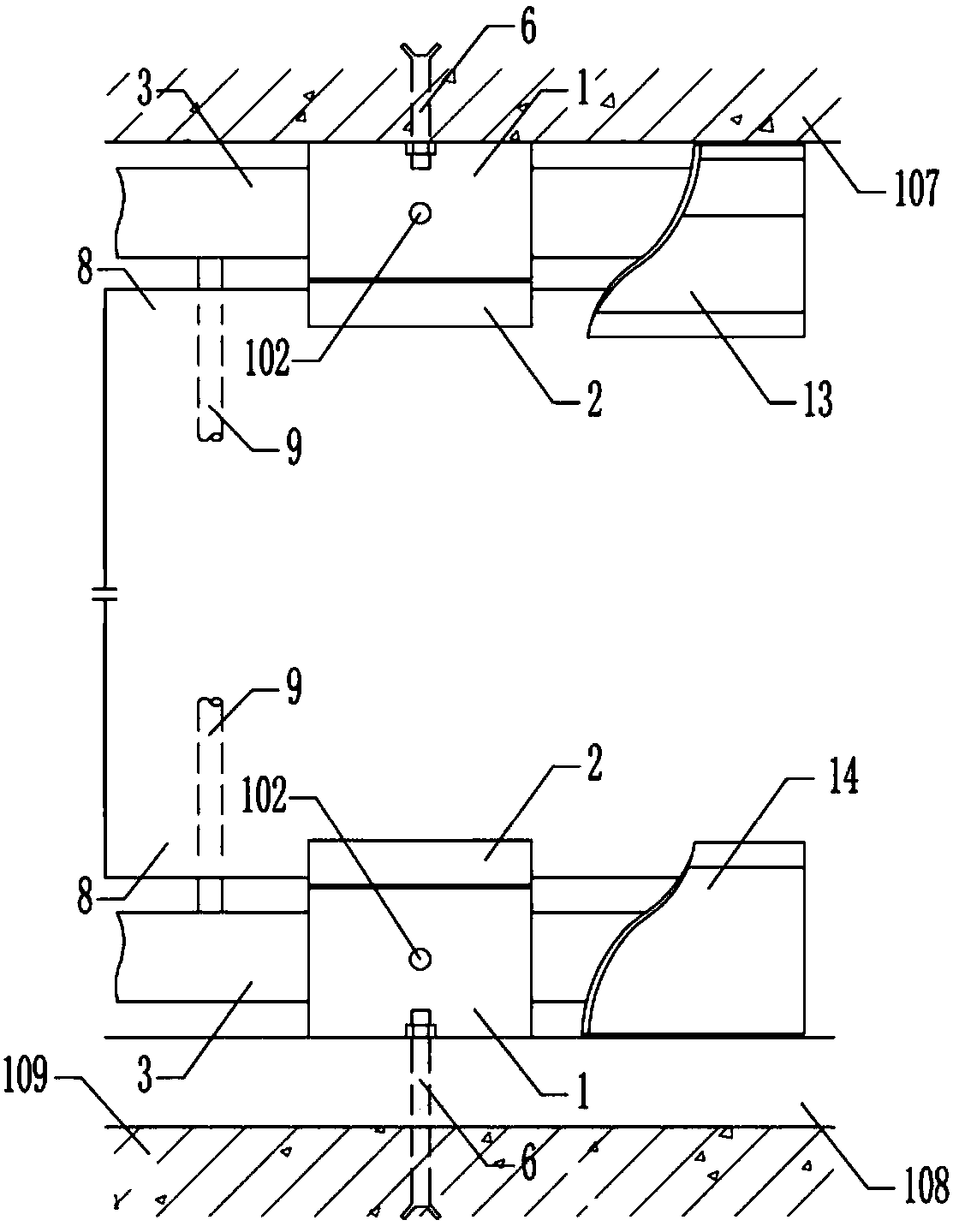

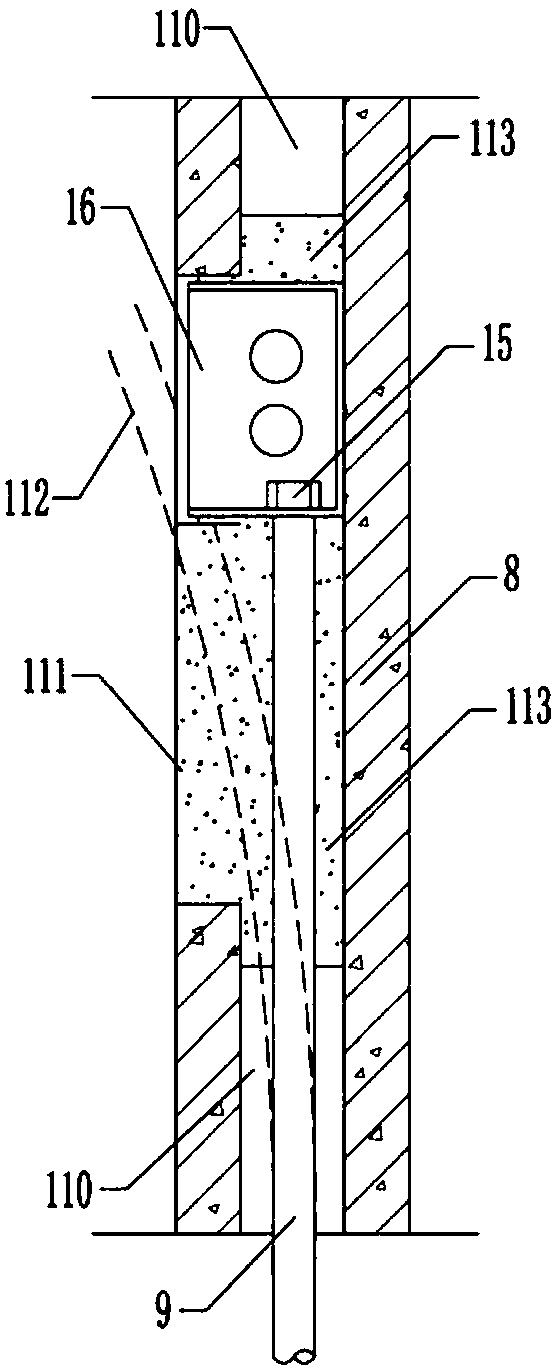

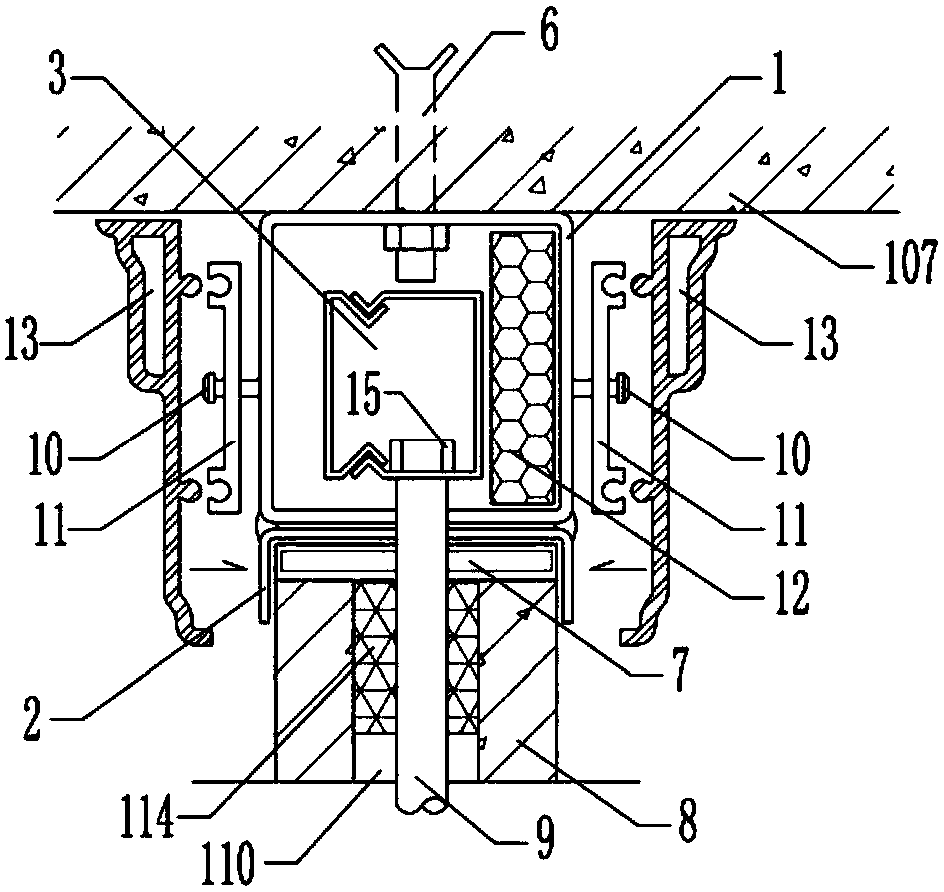

[0037] see Figure 1 to Figure 5 , the embodiment in the illustration is a preferred implementation of the present invention, and the top and bottom ends of the lightweight partition board 8 constituting the partition wall are respectively provided with a top support 201 and a bottom support 202, and the lightweight partition board 8 The spliced partition walls are respectively fixed to the floor and the floor through several top supports 201 and bottom supports 202 . The top support 201 and the bottom support 202 in this embodiment include square steel pipes 1 welded with U-shaped steel channels 2, a prefabricated spacer 4 is set under the bottom support 202, and a triangular wedge is set between the prefabricated spacer 4 and the floor. Block 5, the square steel pipe 1 that passes through the top support and the bottom support is provided with a transverse wire groove 3 and a thermal insulation board 12, and the top support 201 and the bottom support 202 are fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com