Semi-active crown block heave compensation system for deep water drilling operation

A deep-water drilling, semi-active technology, applied in the direction of drilling equipment, drill pipe, drill pipe, etc., can solve the problems of swaying, low reliability of the mechanism, and no locking function of the hydraulic support system, so as to ensure effective work, The effect of lightening the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

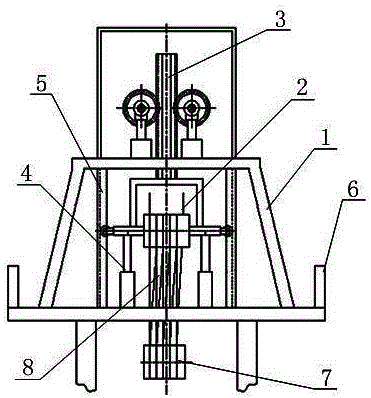

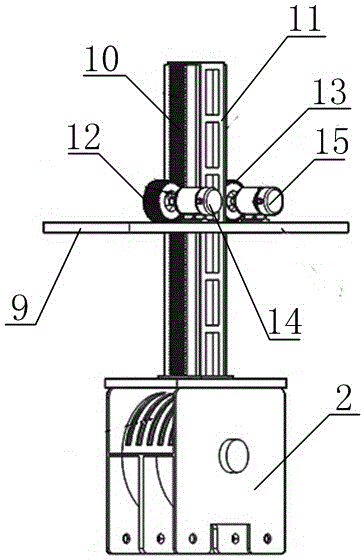

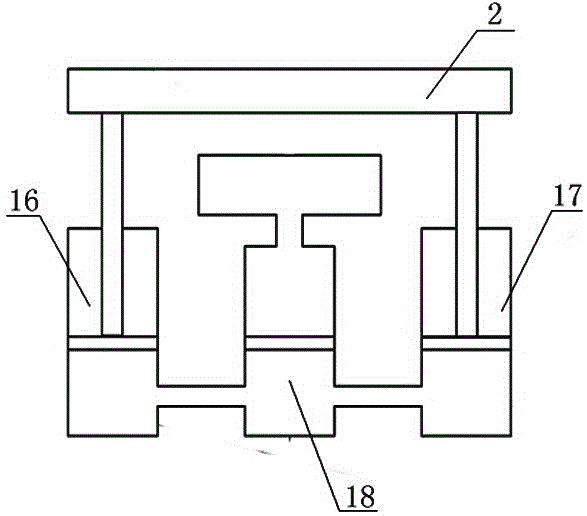

[0038] Such as figure 1 As shown, a semi-active crane heave compensation system for deepwater drilling operations, including a derrick frame 1, a rack and pinion drive compensation mechanism 3, a hydraulic support locking mechanism 4, a guide device 5, and a passive compensation system with passive compensation function. Compensation steel wire rope 8 rocker mechanism 6, floating crane 2 and traveling block 7, said rack and pinion drive compensation mechanism 3 is fixedly installed on the top of the derrick frame 1, guide device 5 is installed in the derrick frame 1, and the floating crane 2 slides Installed on the guide device 5, and can float up and down along the guide device 5, the hydraulic support locking mechanism 4 is installed on the bottom of the derrick frame 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com