Pipeline blow-down pump

A sewage pump and pipeline technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of increasing maintenance costs, affecting the speed of sewage discharge, blockage, etc., to achieve significant energy-saving effects, ensuring stability, and ensuring the effect of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

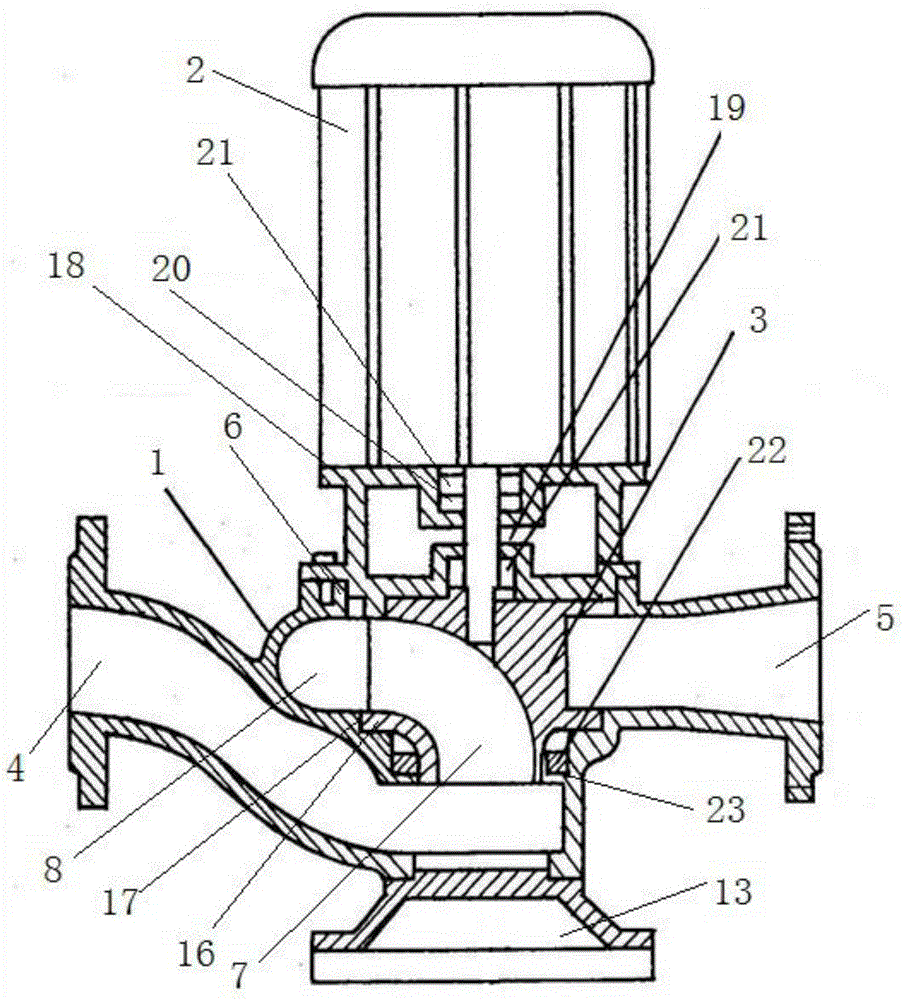

[0025] figure 1 A specific embodiment of the present invention is shown: a pipeline sewage pump, comprising a pump body 1, a motor 2 and an impeller 3, one side of the pump body 1 is a water inlet 4, and the other side of the pump body 1 is a water outlet 5, the There is a motor installation groove 6 above the pump body 1, the motor 2 is arranged in the motor installation groove 6, the impeller 3 is arranged at the end of the output shaft of the motor 2, the impeller 3 is located in the pump body 1, the impeller 3 is a cavity structure, and the cavity The body is provided with a 90° elbow 7, the two ends of the elbow 7 communicate with the cavity, the pump body 1 is provided with an inner cavity 8 opposite the water outlet 5, the bottom end of the elbow 7 communicates with the water inlet 4, and the elbow 7 The top of the water outlet 5 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com