A hydraulic system with good sealing performance and reduced leakage

A sealing performance and hydraulic system technology, which is applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, servo motors, etc., to achieve good control of the hydraulic system, improve oil leakage, and optimize the effect of the cylinder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

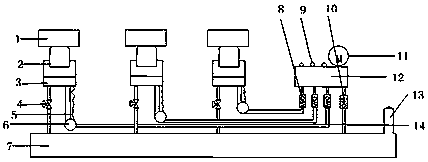

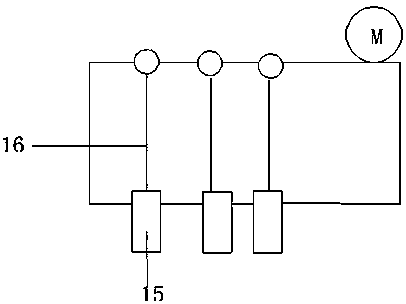

[0021] Such as figure 1 As shown, a hydraulic system with good sealing performance and reduced leakage in the present invention includes a main hydraulic cylinder 12 and a connected motor 11, and three push switches 9 drive three connecting shafts 16 to control three oil pipe interfaces 15. The sub-hydraulic cylinder 3, the oil pipe 14, the diameter of the oil pipe is 10CM, the oil tank 7 and the pump head 2 inside the sub-hydraulic cylinder 3, the pump head 2 supports the heavy object 1, and the oil pipe 14 connecting the main hydraulic cylinder 12 and the sub-hydraulic cylinder 3 is set An oil outlet check valve 8, an oil suction check valve 10 is arranged on the oil pipe 14 connecting the main hydraulic cylinder 12 and the fuel tank 7, a cut-off valve 4 is set on the oil pipe 14 connecting the sub-hydraulic cylinder 3 and the fuel tank 7 and the cut-off valve 4 and the oil tank 7 A pressure gauge is connected between them, a cavity 6 and an air-permeable layer 5 are set on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com