An armored vehicle closed oil tank ventilation device

A ventilation device, oil tank technology, applied in crankcase ventilation, mechanical equipment, engine components and other directions, can solve the problems of diesel engine damage, oil leakage, oil tank deformation, etc., to improve work reliability and safety, solve deformation and The effect of cracking and improving oil leakage problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

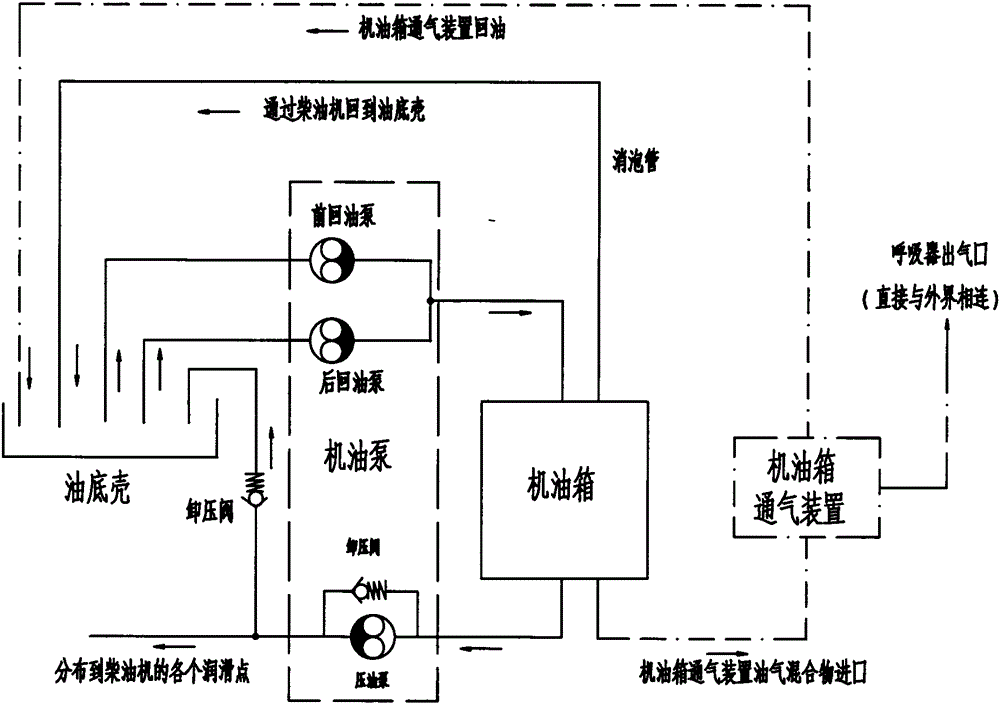

[0012] For the connection method between the oil tank breather and the diesel engine, see figure 1 shown. Add a venting device at the oil tank to transport the oil-air mixture produced by the high pressure of the exhaust gas in the oil tank to the venting device. After the defoaming treatment of the venting device, the lubricating oil returns to the interior of the diesel engine through the oil return port, and the exhaust gas comes from the outlet. The air port is excluded, thereby reducing the gas pressure in the oil tank and ensuring the reliability of the vehicle.

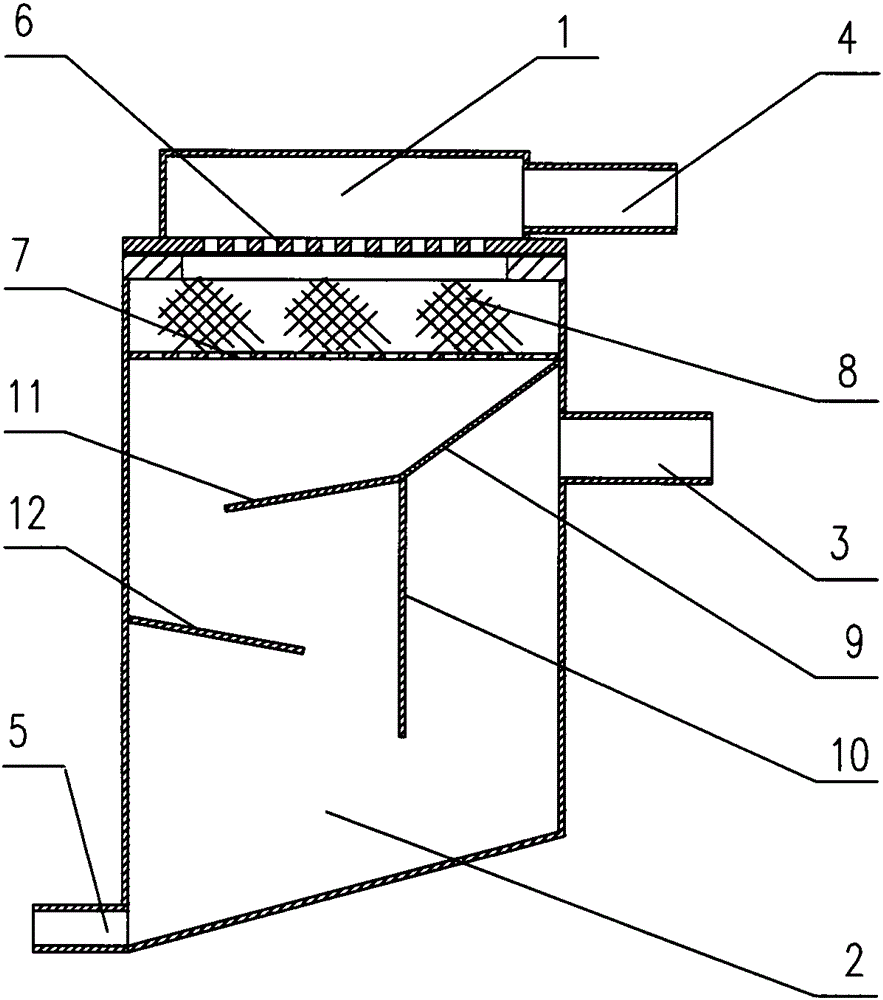

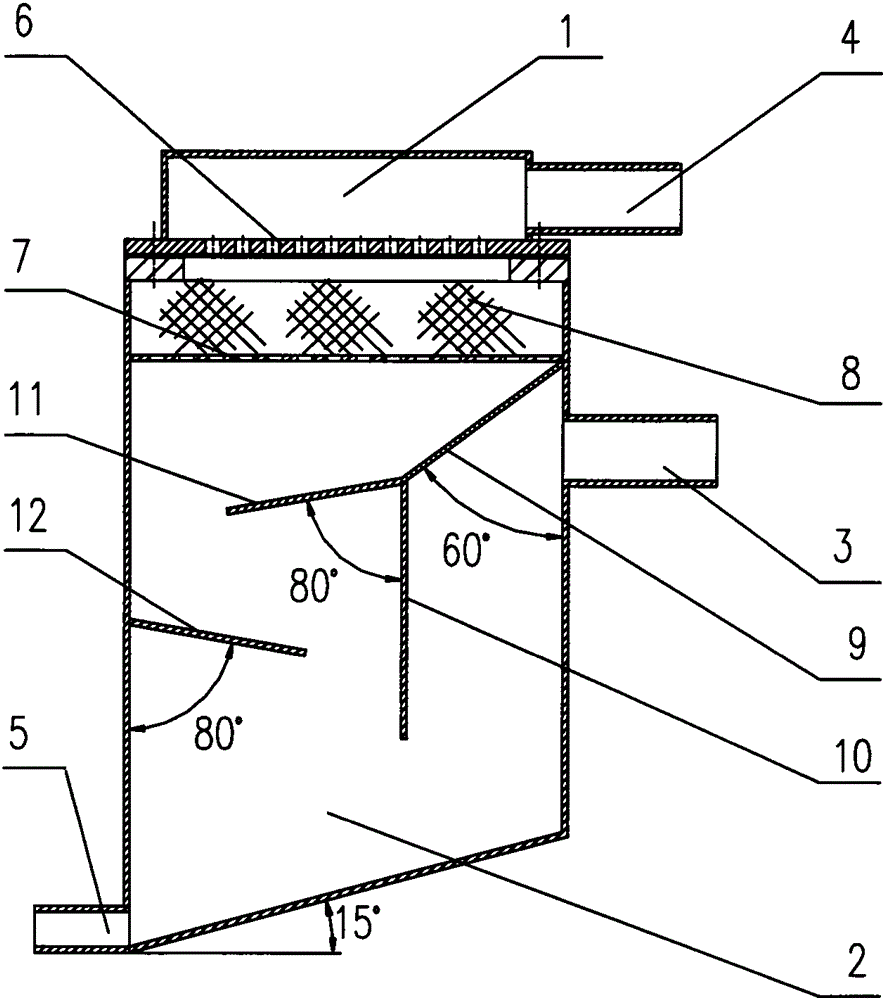

[0013] Attached below figure 2 Specific embodiments of the present invention will be described in detail.

[0014] After the internal pressure of the oil tank increases, the oil-air mixture in the oil tank enters the oil tank ventilator through the oil-air mixture inlet 3 at a certain pressure and flow rate, and first collides with the upper inclined horizontal partition 9 and the upper vertical horizontal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com