Socket type pipe fitting structure

A technology of socket and pipe fittings, which is applied in the direction of pipe/pipe joint/pipe fitting, passing element, sleeve/socket connection, etc., which can solve the problems of increasing construction difficulty, detachment of pipe fittings, and unsatisfactory anti-slip effect of sealing rings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0025] The present invention will be described in detail below with reference to the accompanying drawings and examples.

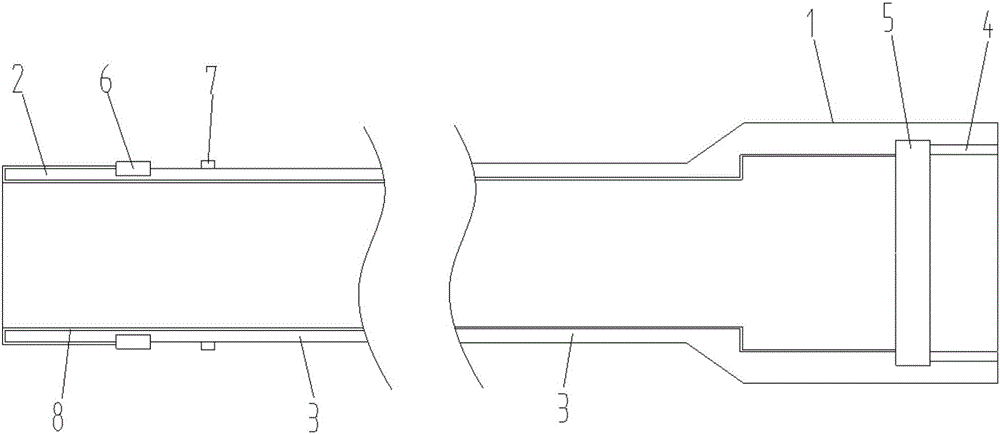

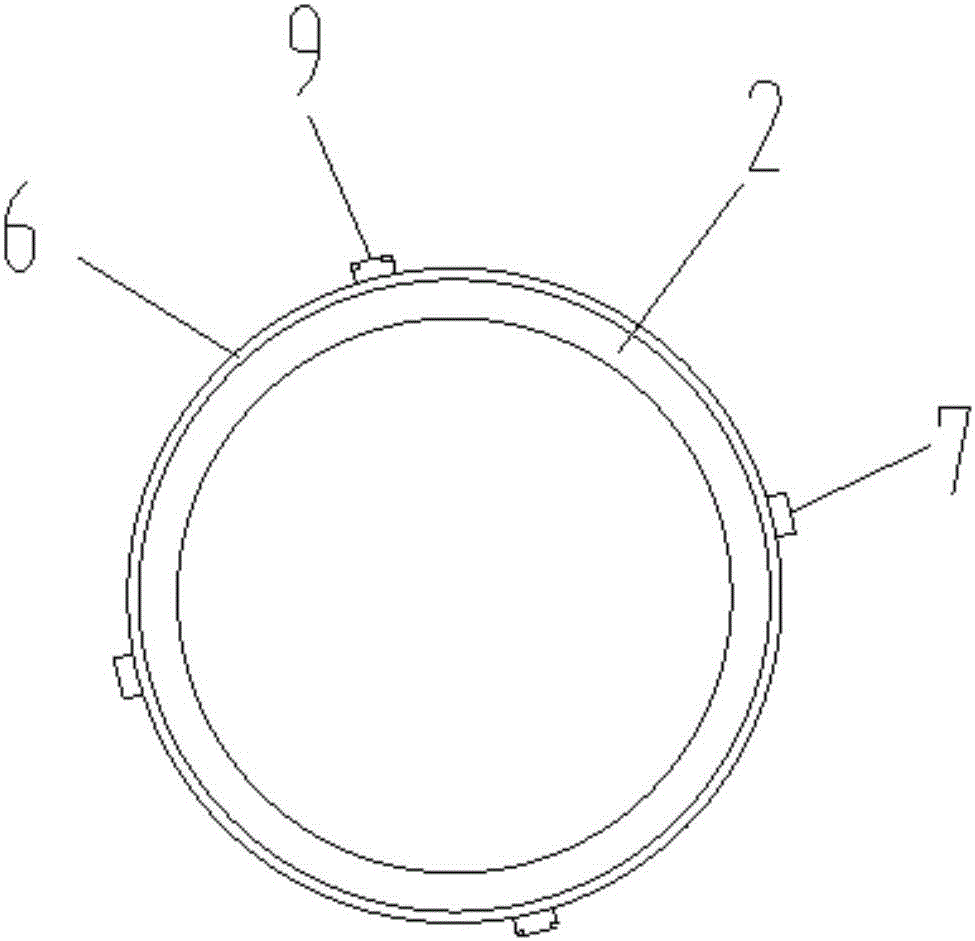

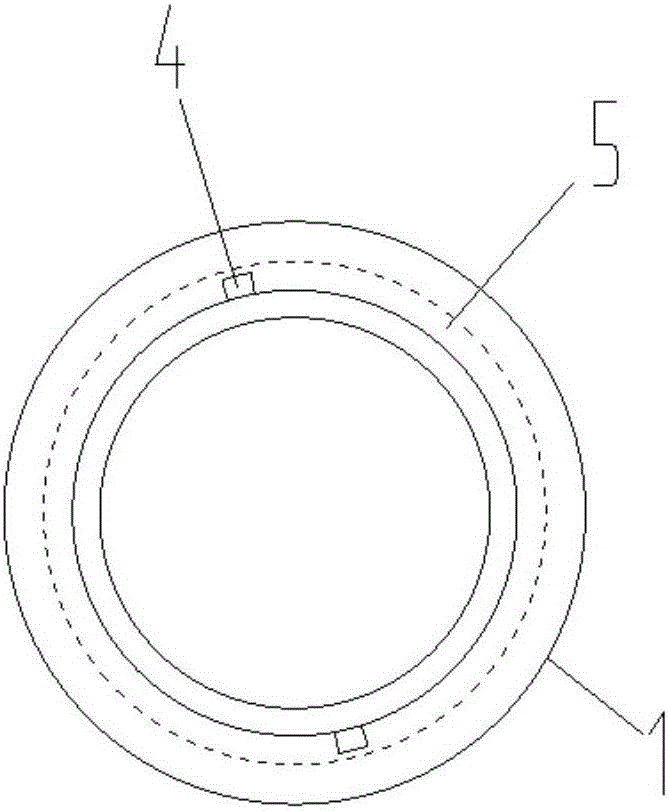

[0026] The socket-type pipe fitting structure of the present invention, as shown in the figure, includes a pipe body 3, and a socket 1 and a socket 2 located at both ends of the pipe body 3 respectively. The central hole is connected with the chute 4, the inner wall of the socket 1 at the end of the chute 4 is radially provided with an inner groove 5, and the outer wall of the socket 2 is sequentially fixed with an anti-off block 7 and a limit block that match the chute 4 9. The distance between the anti-off block 7 and the end face of the socket 2 is smaller than the distance between the limit block 9 and the end face of the socket 2, along the direction of the socket 2 pointing to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com