Dual-light-source system integrated LED vehicle lamp

An LED car light, integrated technology, applied in the field of dual light source system integrated LED car lights, can solve the problems of complex structure, poor installation accuracy, increased cost, etc., and achieve the effect of high light intensity and high heat dissipation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

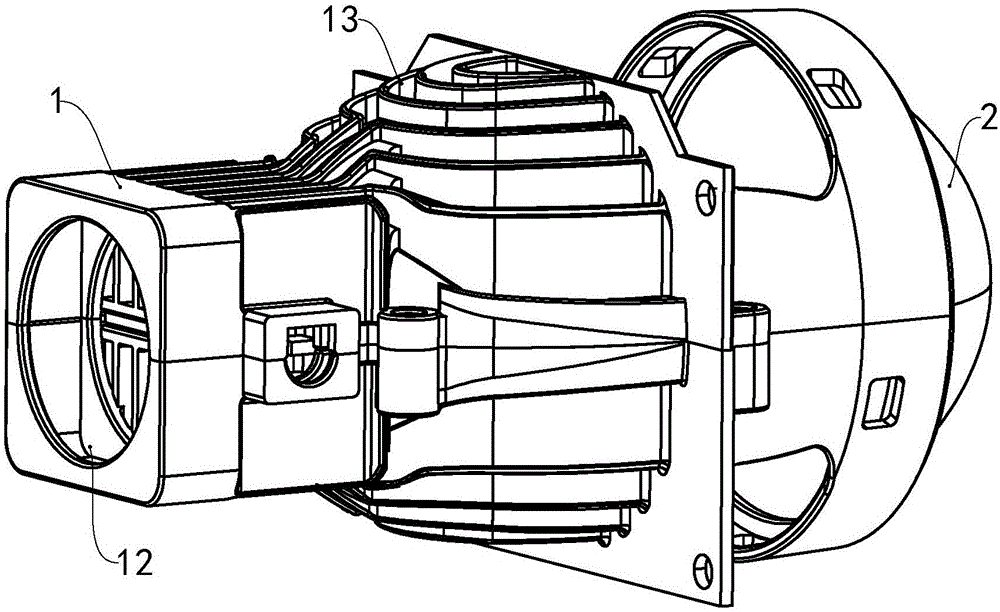

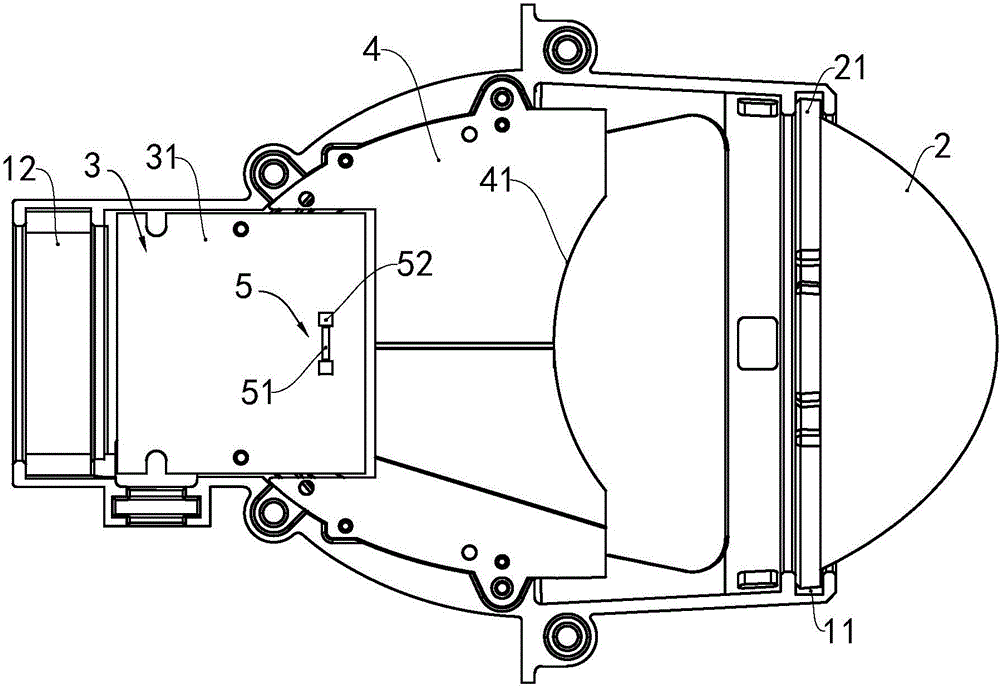

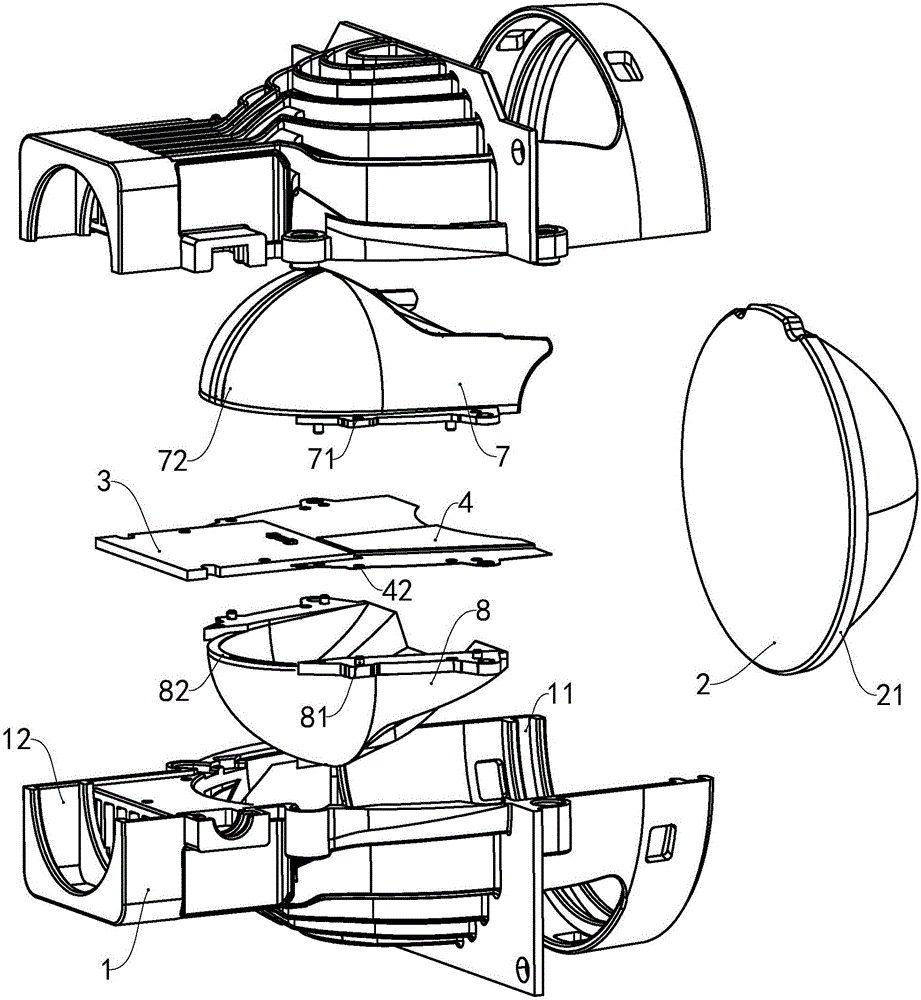

[0034] see figure 1 and figure 2 , this embodiment provides an integrated LED vehicle light with dual light source system, including a heat dissipation bracket 1 and a lens 2, the interior of the heat dissipation bracket 1 forms an accommodation cavity, the lens 2 is installed on one end of the heat dissipation bracket 1, and the first end of the heat dissipation bracket 1 A first installation groove 11 is opened, and a boss 21 matching with the first installation groove 11 is provided on the circumference of the lens 2 , and the boss 21 is clamped in the first installation groove 11 . The second end of the heat dissipation bracket 1 is provided with a second installation slot 12, and a cooling fan (not shown) is installed in the second installation slot 12, and the cooling fan blows the formed horizontal airflow to the direction of the cooling bracket 1 and the installation plate 3, for The heat dissipation bracket 1 and the mounting plate 3 dissipate heat. The heat dissi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com