A sealed chassis with multi-module independent cooling air ducts

A heat dissipation air duct and multi-module technology, applied in the field of machinery and circuits, can solve problems such as large air pressure and flow, low heat transfer efficiency, and large noise, and achieve the goals of solving heat dissipation problems, good environmental adaptability and electromagnetic compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

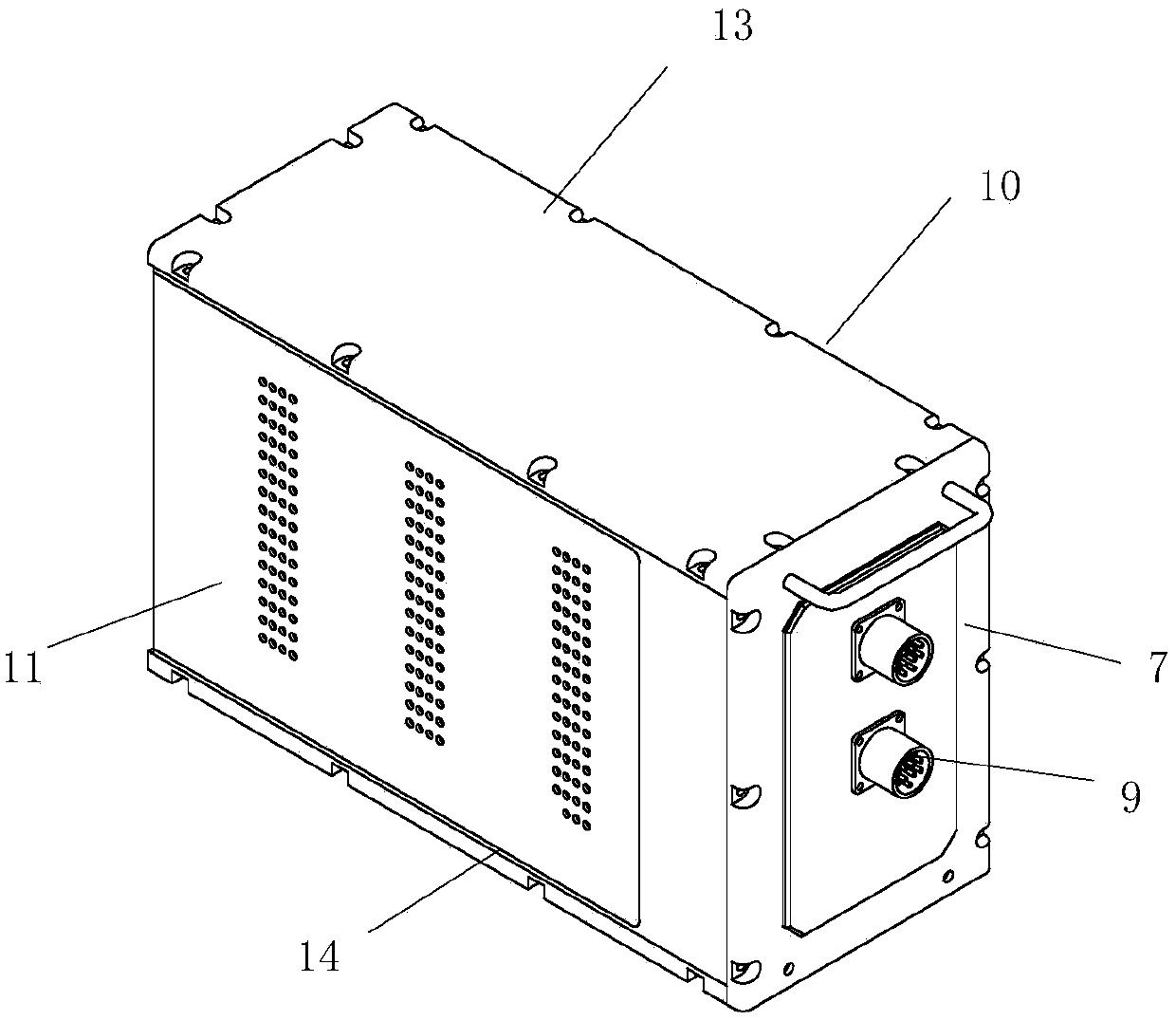

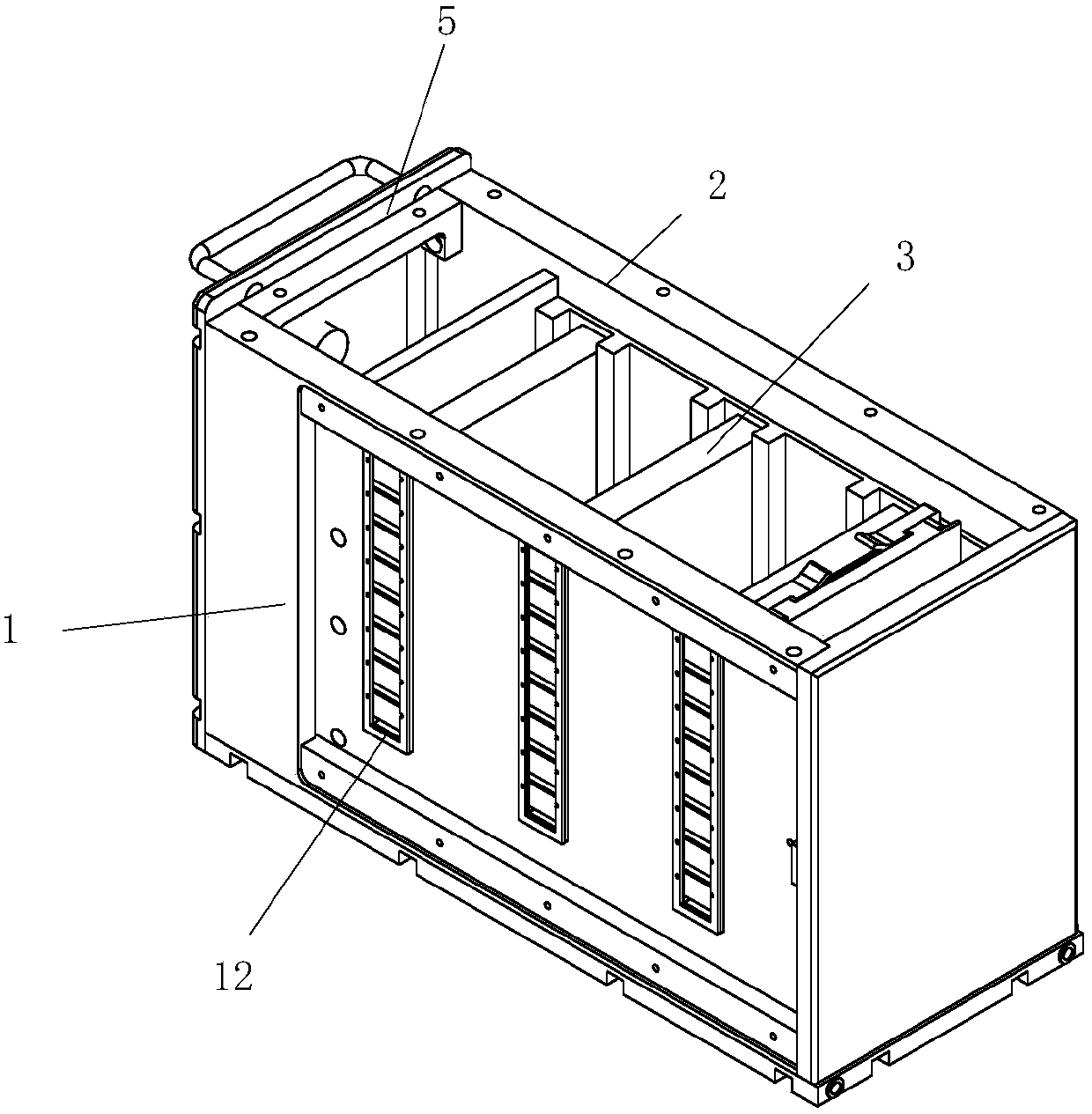

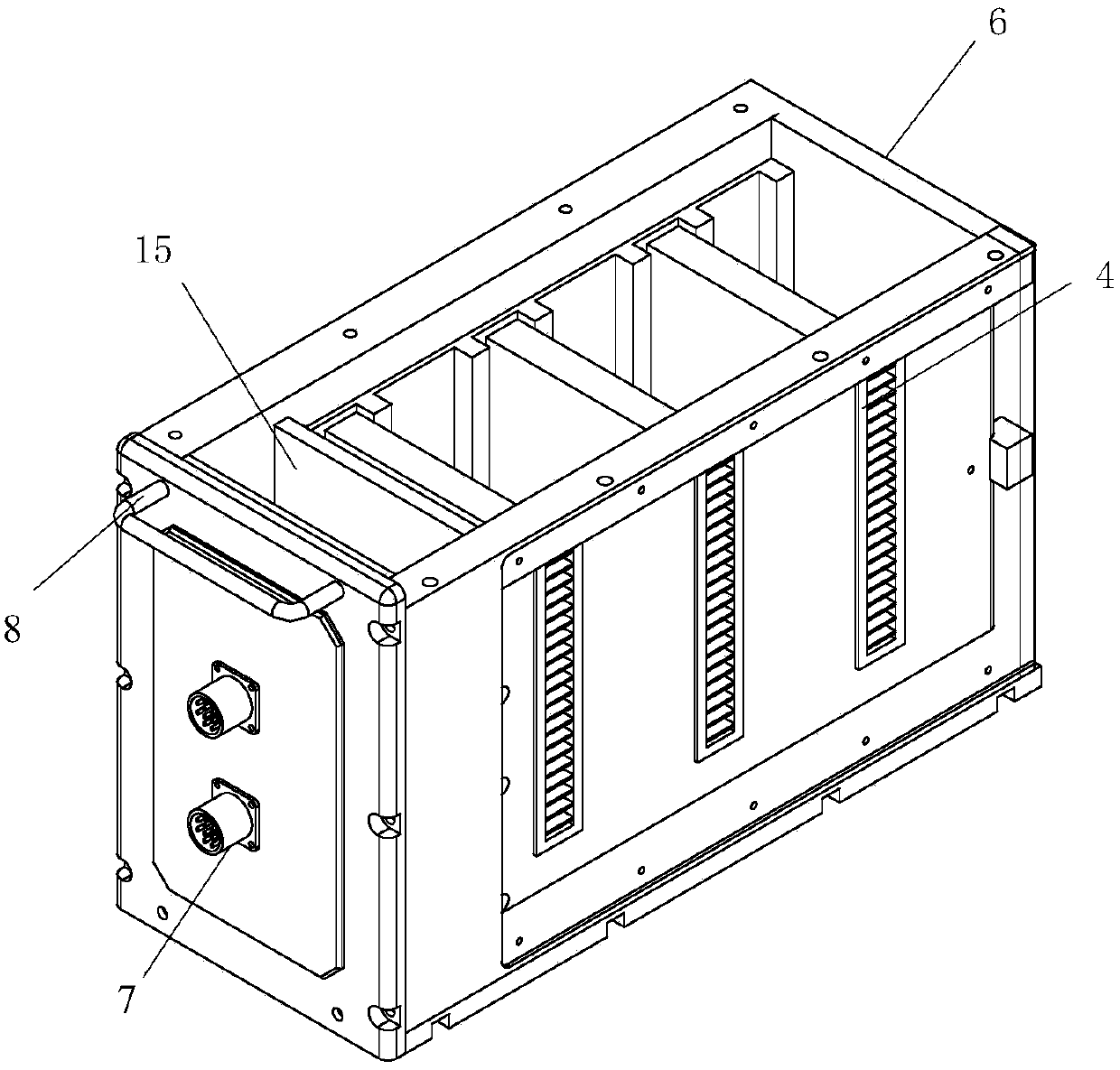

[0022] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0023] The innovation of the chassis design lies in the realization of the structure of multiple independent sealed air ducts and the uniform heat exchange requirements of multiple air ducts.

[0024] The structural form of the chassis is the same as that of the traditional ATR chassis, and the common standard motherboard is installed on the bottom of the chassis. After each CPCI / VPX plug-in is plugged into the motherboard, it is installed and fixed on the locking surface of each slot on the side wall of the chassis by means of a wedge locker by friction. In the traditional ATR case design, the side plate is the core part of heat exchange, the left and right side walls of the case are made of soft aluminum material, the inner wall is milled into standard slots to lock the end faces, and the outer wall is brazed with stacked cooling fins. The fins are made of alu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com