Phase change heat storage type heating system used for new energy automobile

A new energy vehicle, phase change heat storage technology, applied to vehicle components, heating/cooling equipment, air handling equipment, etc., to achieve high thermal efficiency, high thermal density, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

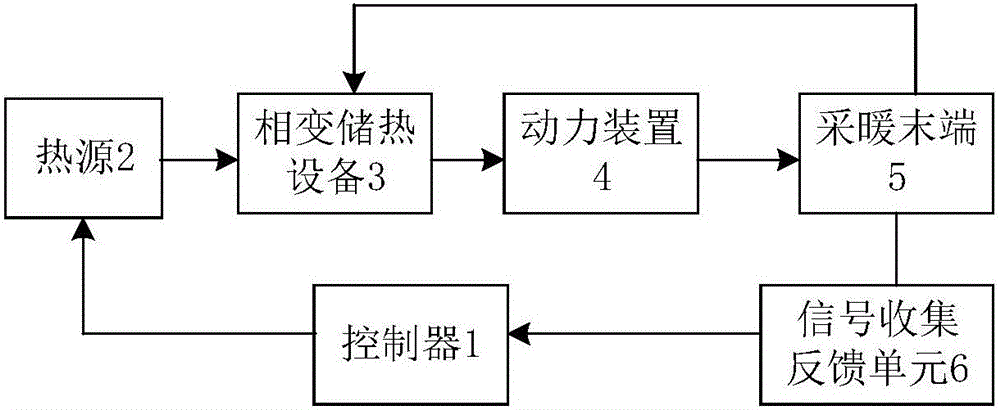

[0028] Such as figure 1 As shown, a phase change heat storage heating system for new energy vehicles is installed in the new energy vehicles to provide heating for the new energy vehicles. The system includes phase change heat storage equipment 3, a power unit 4 and Heating end 5. The circulating medium in the phase change heat storage device 3 is sent to the heating terminal 5 by the power unit 4 , and the circulating medium after heat exchange is returned to the phase change heat storage device 3 .

[0029] The heat storage material in the phase change heat storage device 3 is an inorganic nano phase change heat storage material. Under the same volume, the heat storage of the phase change material is equivalent to the heat converted from the stored electricity of the lithium battery, and the cost is lower than that of the lithium battery.

[0030] The phase change heat storage device 3 itself has an electric heating system, and the phase change heat storage device 3 can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com