Novel range hood

A range hood, a new type of technology, applied in the direction of removing oil fume, household heating, lighting and heating equipment, etc., can solve the problems of splashing oil and water, unable to collect and gather smoke, escape, etc., and achieve the effect of good smoke exhaust effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

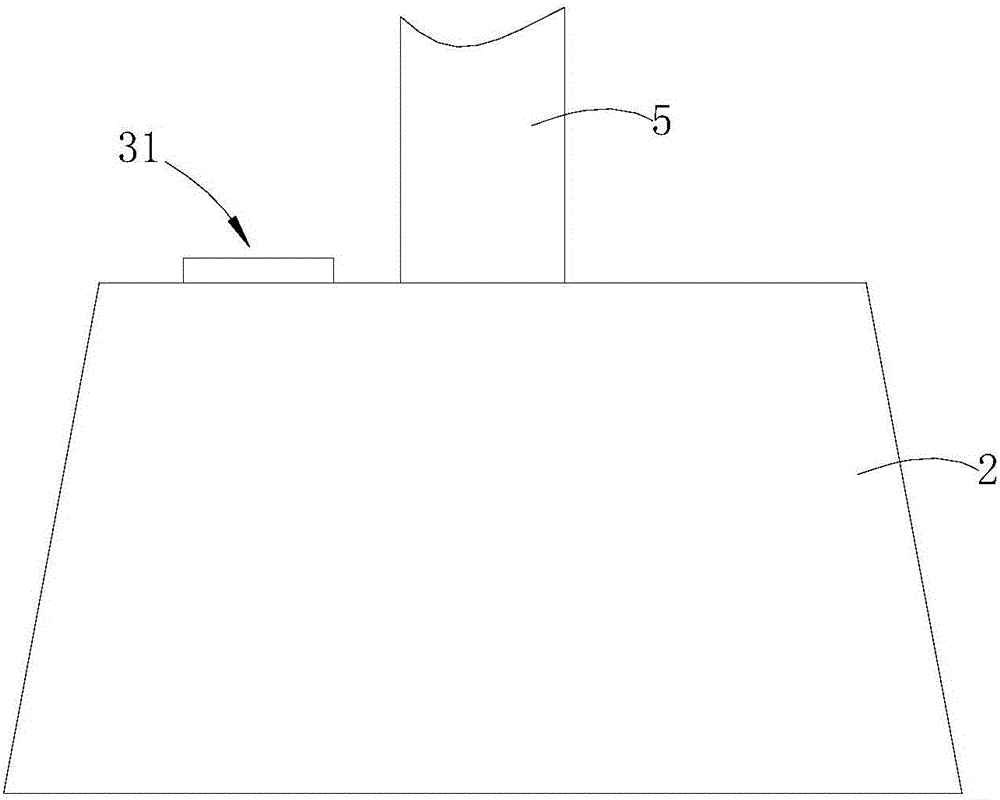

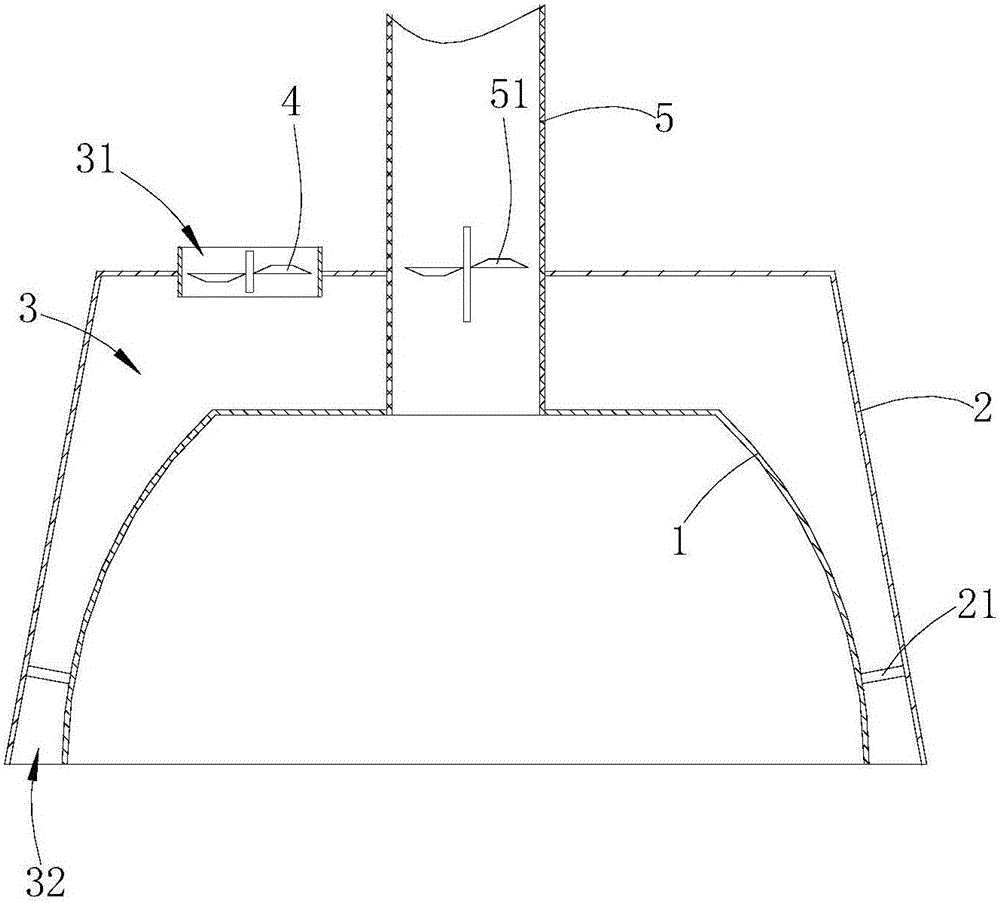

[0014] Such as Figures 1 to 3 shown

[0015] The novel range hood comprises a guide cover 1 , a smoke exhauster 51 , a smoke exhaust pipe 5 , an outer casing 2 and an air intake fan 4 .

[0016] The shroud 1 is roughly in the shape of an inverted funnel, the opening of the shroud 1 is downward, the outer shell 2 is arranged outside the shroud 1, and the outer shell 2 and the shroud 1 are fixed by several connecting columns 21, and the guide The space between the flow cover 1 and the outer casing 2 forms a distribution chamber 3, and the rear end surface of the outer casing 2 is provided with an air inlet 31 communicating with the outside, and the air inlet 4 is arranged at the air inlet 31, and the lower side of the outer casing 2 is connected to the air guide There is a gap between the front side, left side and right side of the cover 1, and the gap forms a concave air outlet 32 on the lower end surface of the distribution cavity 3, and the air outlet 32 is distributed ...

Embodiment 2

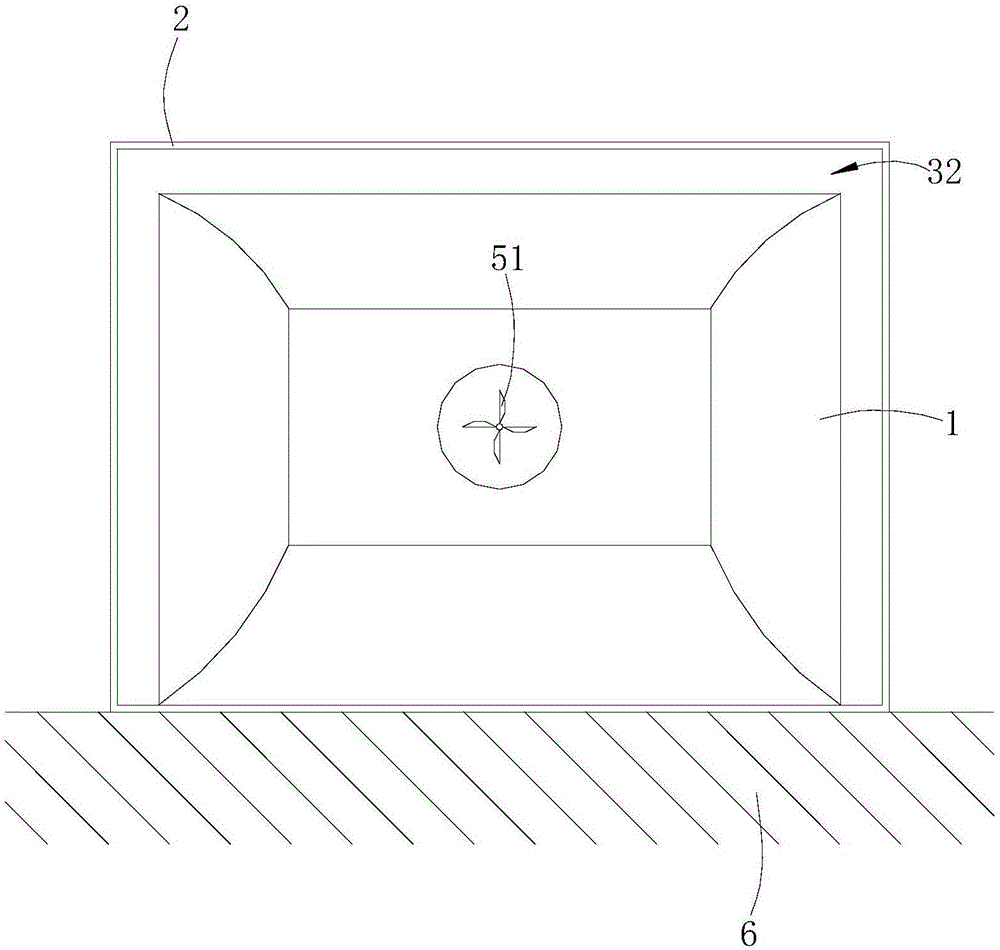

[0022] Such as Figure 4 shown

[0023] The difference between this embodiment and Embodiment 1 is that there are gaps between the lower side of the outer casing 2a and the front side, rear side, left side and right side of the shroud 1a, and the gap forms a square ring on the lower end surface of the shunt cavity. The air outlet 32a, when the novel range hood of this embodiment is installed on the top of the wall, when the side wall of the housing is not in contact with the wall, the annular air outlet 32a can form an air curtain to the four sides of the oil fume source.

[0024] In addition, if the side wall of the new range hood of this embodiment is installed on the wall 6a, a baffle 7a can be set to cover any side of the annular air outlet 32a, so that the original square annular air outlet becomes concave. tuyere.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com