Electric direct drive wind power pitch device

A direct-drive, wind power technology, applied in the direction of engine, wind power generation, wind turbine, etc., can solve the problem of difficulty in replacing the timing belt, and achieve the effect of high transmission efficiency, simple mechanical connection structure and fast speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

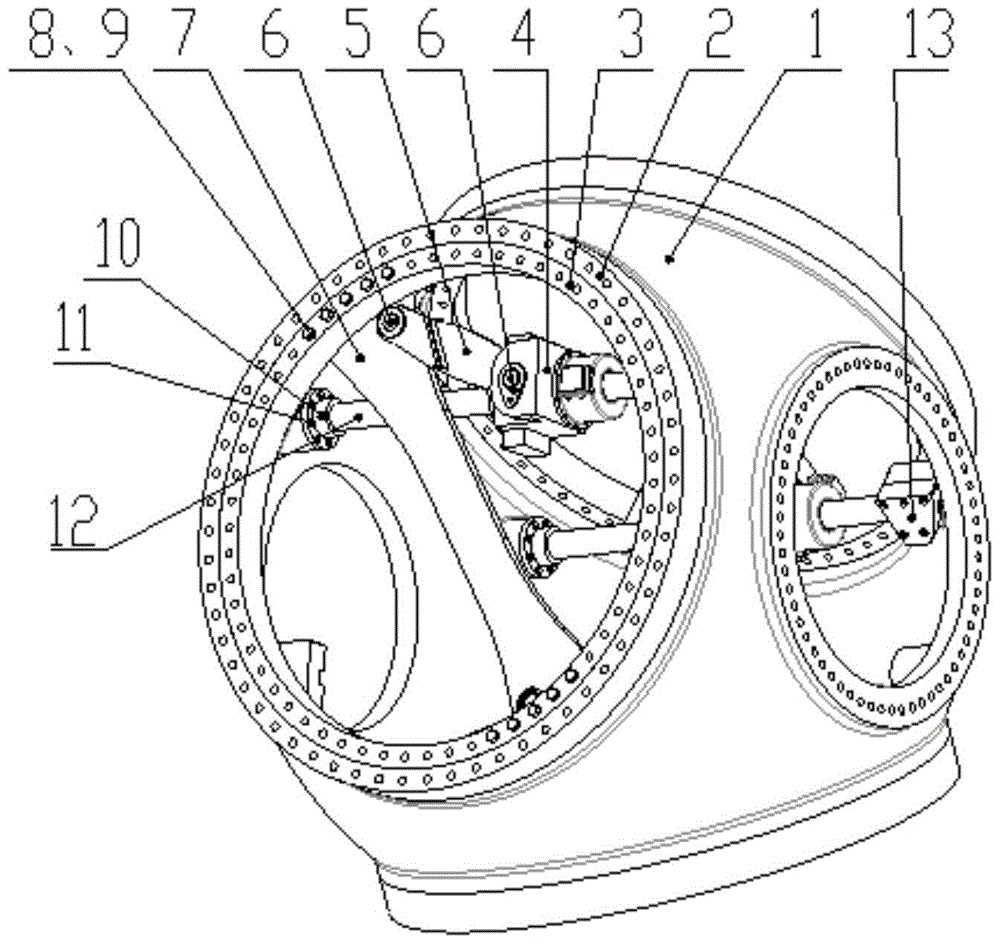

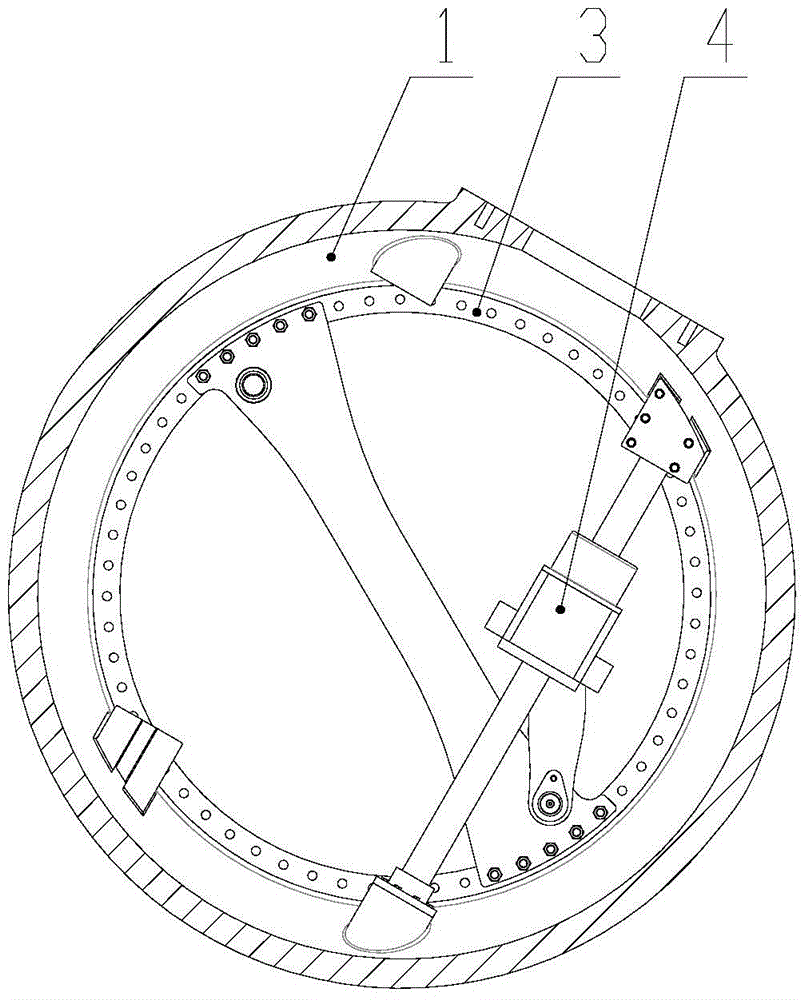

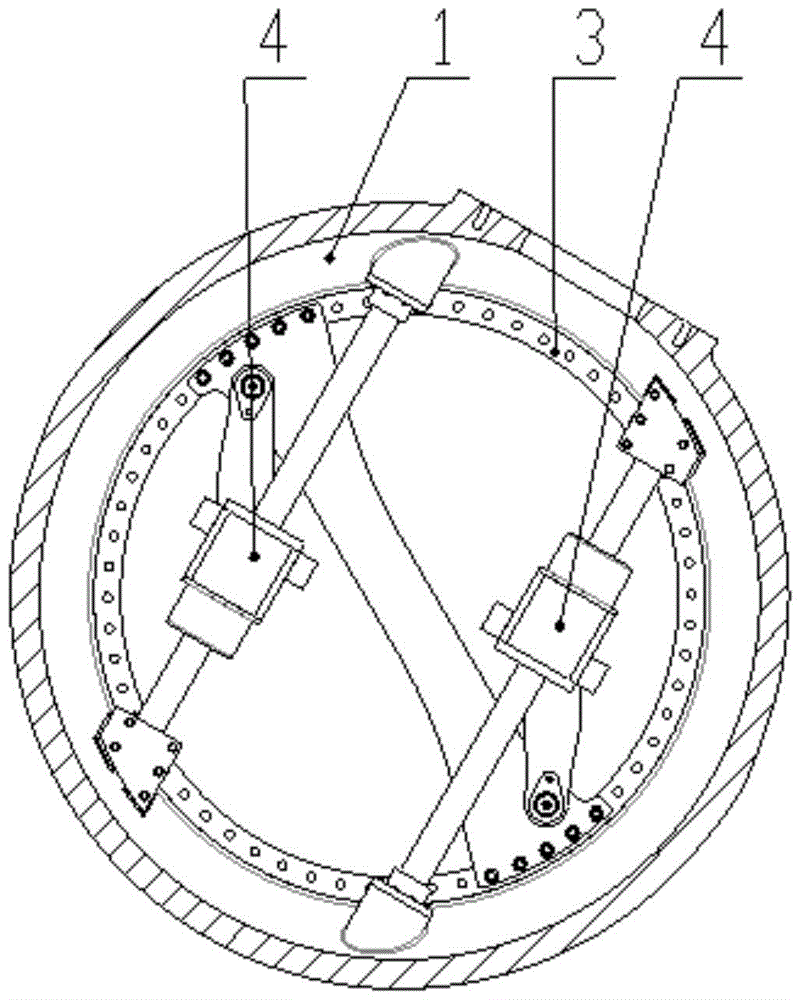

[0025] The present invention will be further described below in conjunction with the drawings.

[0026] There are three blades of the wind turbine. A complete set of pitch system requires three electric direct-drive wind power pitch devices of the present invention (hereinafter referred to as the pitch drive system), and each pitch drive system of the present invention drives one blade. And the three electric pitch drive systems are evenly arranged in the hub at 120 degrees. In order to make the description concise, only a single pitch drive system is introduced, and the linkage of the three can be controlled by the central controller.

[0027] The present invention includes a linear drive mechanism 4, a connecting rod 5, a mounting frame 7, a hub 1, a pitch bearing outer ring 2 and a pitch bearing inner ring 3. The pitch bearing outer ring 3 is fixed on the hub 1, and the pitch bearing inner ring 3 and the pitch bearing outer ring 2 are in a rotational fit. The two ends of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com