Focusing assembly for track lamp and track lamp using focusing assembly

A track light and focusing technology, which is applied to semiconductor devices of light-emitting elements, parts of lighting devices, cooling/heating devices of lighting devices, etc. Assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

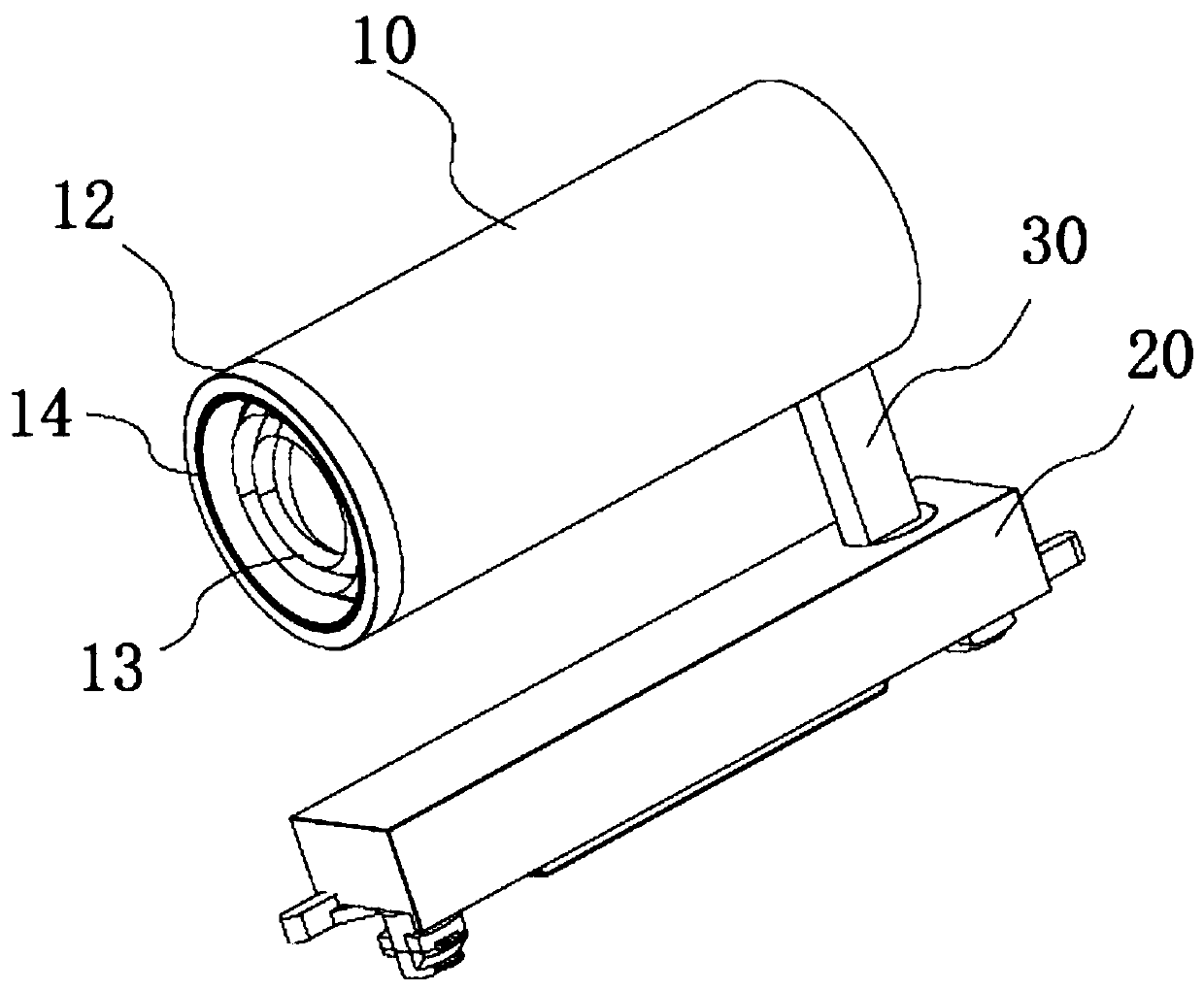

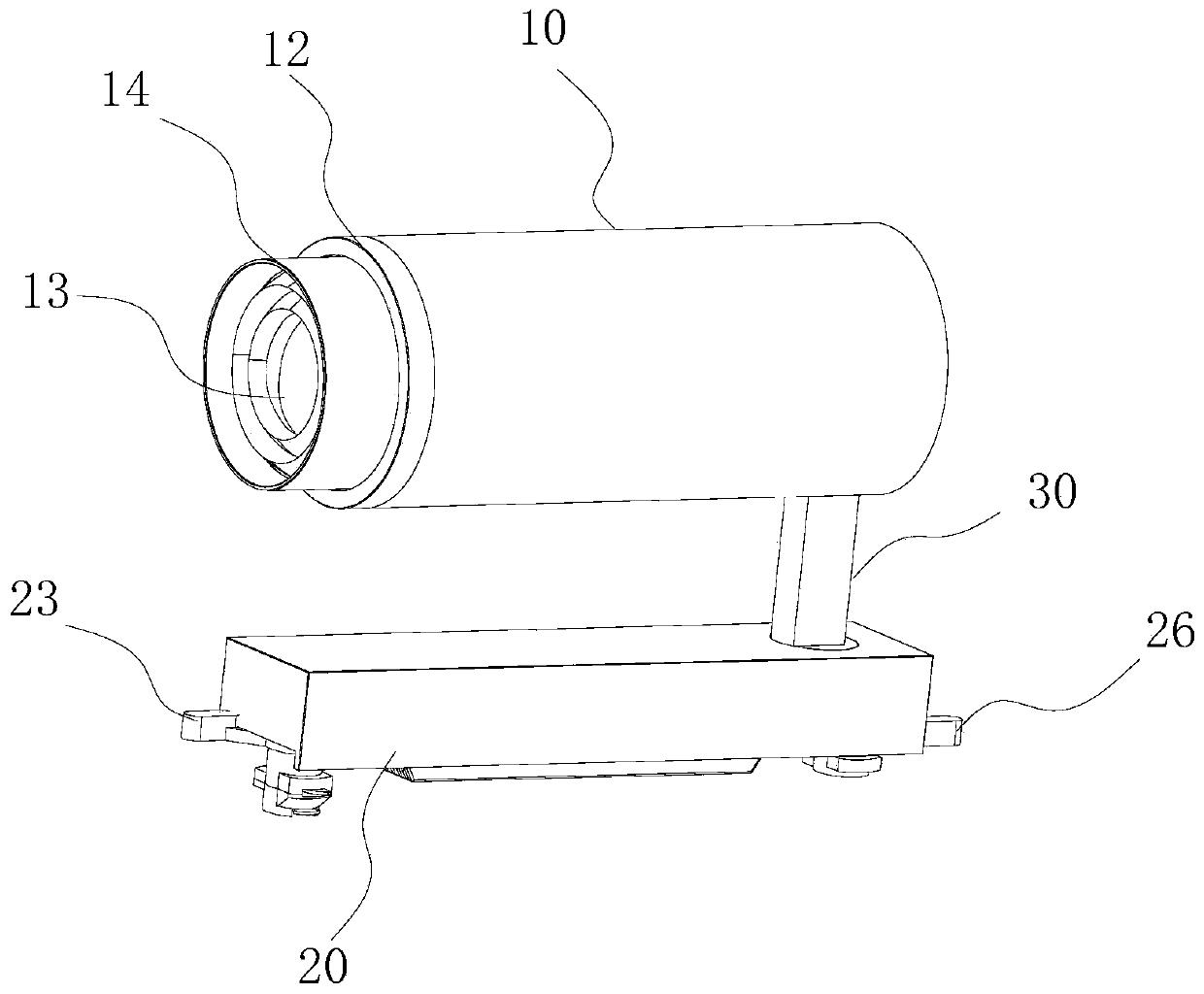

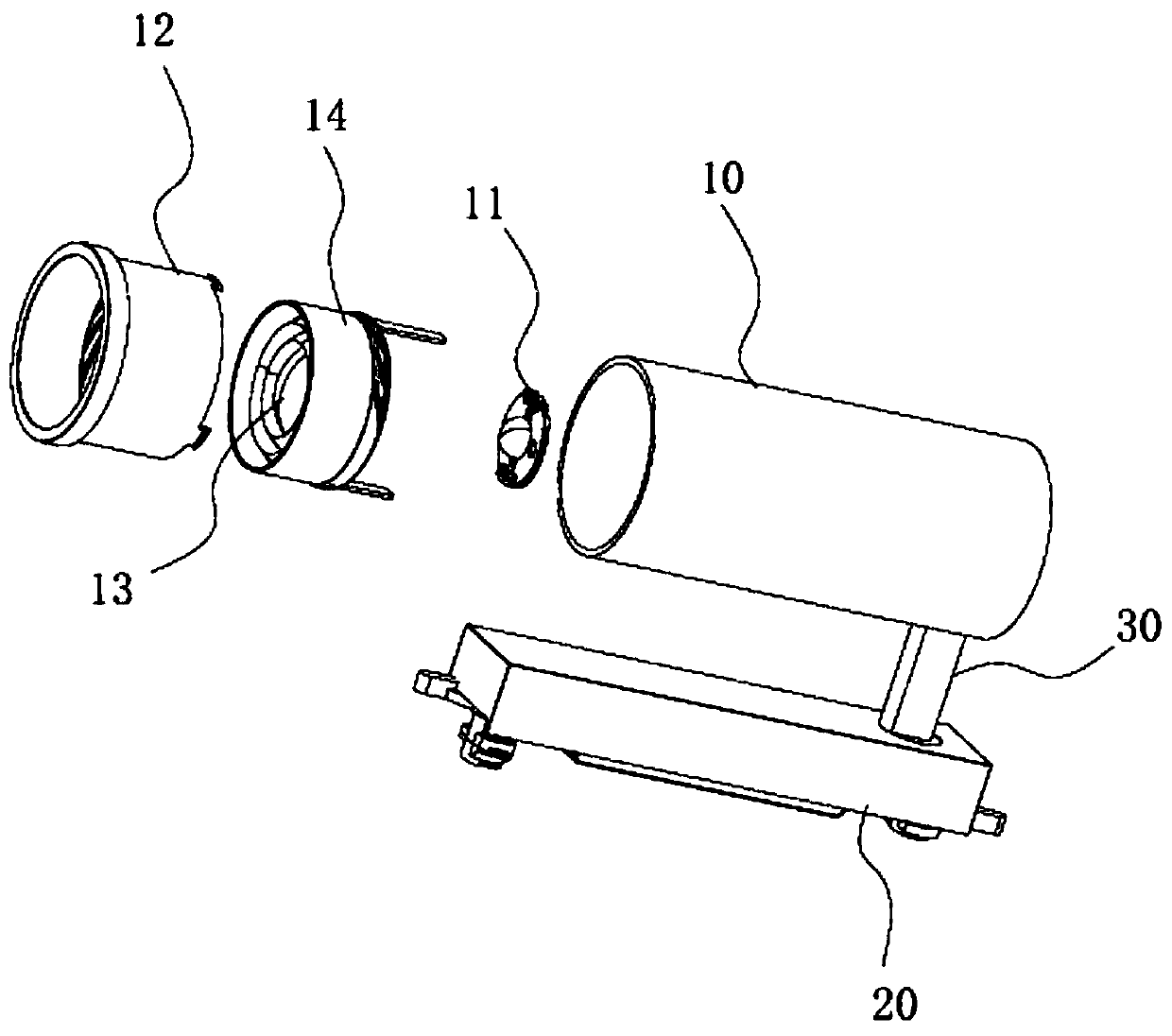

[0041] Such as figure 1 with image 3 As shown, the focusing assembly for track lights of this embodiment includes a coaxially arranged lamp tube 10, a light source, a condenser 11, a zoom lens 13, and a rotating sleeve 12 and a translation sleeve 14, and a condenser 11 Consists of an integrally formed concave-convex lens 111 and a disc 112, such as Figure 4 with Picture 10 The lamp tube 10 shown includes a lamp tube body 101 and a lamp tube rear cover. A heat dissipation base 102 is provided in the middle of the lamp tube body 101. The heat dissipation base 102 includes an integrally formed base center column and a plurality of heat dissipation fins 104. , The heat dissipation fins 104 are arranged radially outwardly along the center post of the base, one end of each heat dissipation fin 104 is connected with the center post of the base, and the other end is connected with the inner wall of the lamp tube body 101.

[0042] A light source, a meniscus lens 111, and a zoom lens 13...

Embodiment 2

[0054] On the basis of embodiment 1, the focusing assembly for track lights of this embodiment has the following deformations:

[0055] Such as Figure 13 As shown, the front end of the rotating sleeve 12 is no longer provided with a scale ring 124, or a scale value is directly set on the end surface of the front end of the rotating sleeve 12. The rotating sleeve 12 is placed in the lamp tube 10 during assembly, and the front end of the rotating sleeve 12 It is arranged flush with the front end of the lamp tube 10, or the front end of the rotating sleeve 12 is slightly lower than the front end of the lamp tube 10 so that the rotating sleeve 12 is completely placed in the lamp tube 10, and the front end of the rotating sleeve 12 is away from the lamp tube The front end of 10 should not be too far away, subject to the user’s finger touch. An internal thread is provided on the inner wall of the front end of the rotating sleeve body. The translation sleeve 14 includes a translation sl...

Embodiment 3

[0057] On the basis of Embodiment 2, the focusing assembly for track lights of this embodiment has the following deformations:

[0058] The zoomable track light also includes a honeycomb panel 50 adapted to the translation sleeve 14, such as Figure 14 with Figure 15 As shown, the honeycomb plate 50 is a circular thin plate whose diameter is adapted to the inner diameter of the translation sleeve 14, so that the honeycomb plate 50 can be fixedly arranged in the translation sleeve 14, and the translation sleeve 14 and the rotation sleeve 12 are placed In the lamp tube 10, and the honeycomb panel 50 is arranged in front of the zoom lens 13, while not affecting the light transmission, it can prevent the light projected by the zoom lens 13 from generating glare and realize the anti-glare function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com