Differential Pressure Driven Expanders for Cryogenic Refrigerators

A low-temperature refrigerator and differential pressure drive technology, which is applied in the field of expanders, can solve problems such as obstruction of the reciprocating motion of the ejector, large loss of high-pressure helium, and reduced energy utilization rate, so as to improve the utilization rate of work and increase the cooling capacity , the effect of exquisite equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

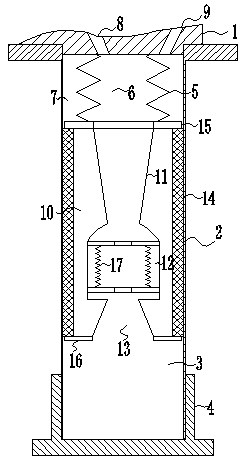

[0014] Such as figure 1 As shown, the differential pressure driven expander of the present invention includes a motor, a gas distribution structure, an intake and exhaust seat 1, a cylinder assembly 2, a piston assembly, a cold chamber 3 and a cold head heat exchanger 4, and the intake and exhaust A wave spring 5 is fixedly connected between the seat and the piston assembly, and the wave spring divides the space between the intake and exhaust seat and the piston assembly into an inner cavity 6 and an outer cavity 7, and the piston assembly separates the inner cavity from the cold cavity and The cold cavity communicates with the outer cavity, the intake and exhaust seat is provided with a main intake and exhaust port 8 in the inner cavity, and the auxiliary intake and exhaust port 9 is provided with the intake and exhaust seat in the outer cavity.

[0015] The method o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com