Automatic mechanical arm device

A manipulator and automatic technology, applied in metal processing and other directions, can solve the problems of alarming labor waste, high labor intensity and high labor cost, and achieve the effect of neatly receiving materials and improving work utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

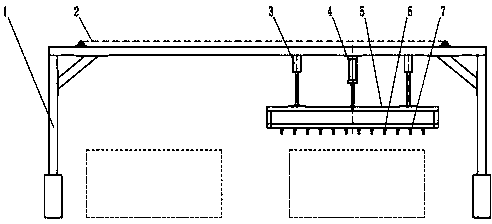

[0009] As shown in the figure, an automatic manipulator device is composed of a gantry frame, a synchronous belt transmission mechanism, a guide rod, a main cylinder, a fixed frame, a connecting seat, and a pneumatic suction cup. The gantry frame is welded by square pipes, and the gantry frame is rectangular. Structure, the upper part is equipped with a synchronous belt transmission mechanism, the middle is installed with a guide rod and a main cylinder, the main cylinder is connected to the fixed frame, the fixed lower part is equipped with a connecting seat, and the lower end of the connecting seat is equipped with N pneumatic suction cups, and the suction cup absorbs the finished material and then the timing belt The transmission mechanism moves to the finished product table to improve work efficiency.

[0010] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com