Paperboard dividing and cutting machine

A technology of slitting machine and cardboard, which is applied in the direction of metal processing, etc., can solve the problems of high price units of automatic die-cutting machines, large size and specification errors of finished products, and inability to meet mass production, so as to avoid die-cutting efficiency Low cost, improved cutting efficiency, and reduced auxiliary adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

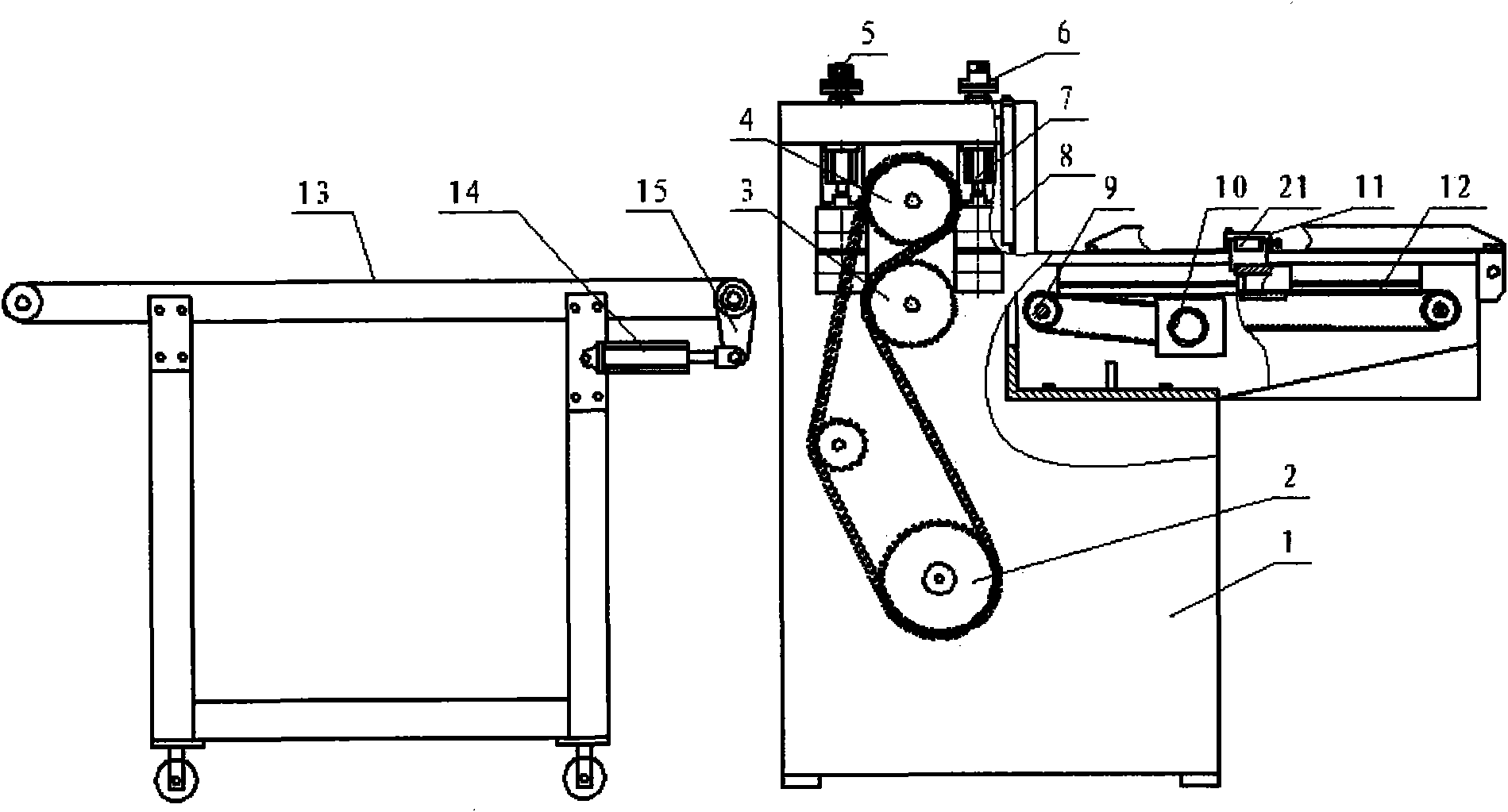

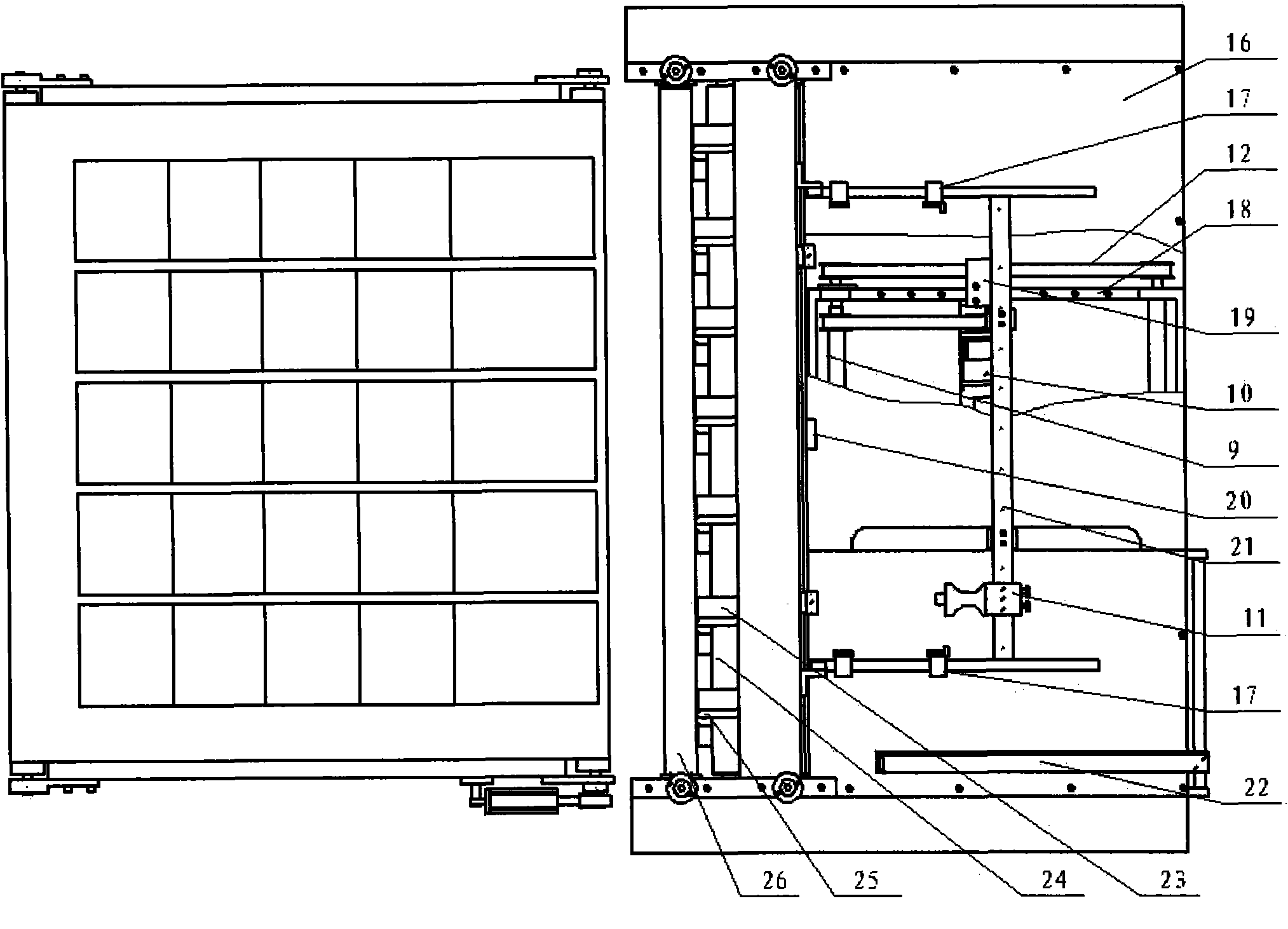

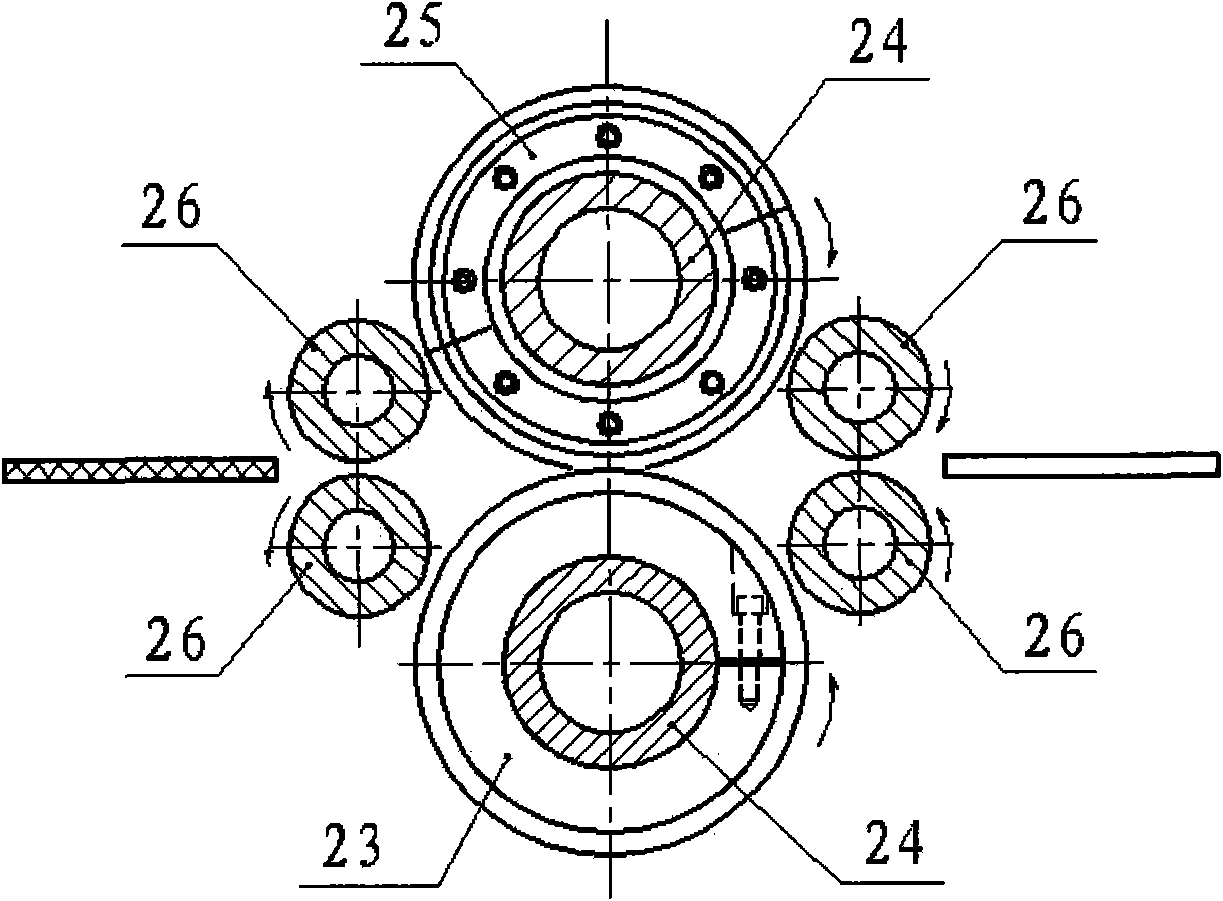

[0027] Next, the cardboard slitting machine of the present invention will be described in detail below with reference to the accompanying drawings.

[0028] The cardboard slitting machine of the present invention comprises a frame, a paper guide mechanism on the frame, and a paper cutting mechanism, the paper cutting mechanism is on one side of the paper guiding mechanism in the horizontal direction, and the paper cutting mechanism is arranged behind There is a paper delivery mechanism, and the paper guide mechanism sends the paper to be cut into the paper cutting mechanism for cutting, and finally the paper delivery mechanism gathers the cut paper. A thickness adjusting device is also arranged above the paper cutting mechanism. The thickness adjustment device includes a thickness adjustment cylinder, a thickness adjustment locking screw, and a thickness adjustment pad. The thickness adjustment cylinder drives the thickness adjustment locking screw and the thickness adjustment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com