Device for treating organic solvent in chemical exhaust gas

A technology of organic solvents and chemical tail gas, applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve problems such as easy leakage of activated carbon particles in activated carbon adsorbers, damage to expander rotors, increase operating costs, etc., to achieve reduction Effect of exhaust gas separator, reduction of cooling loss, and reduction of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

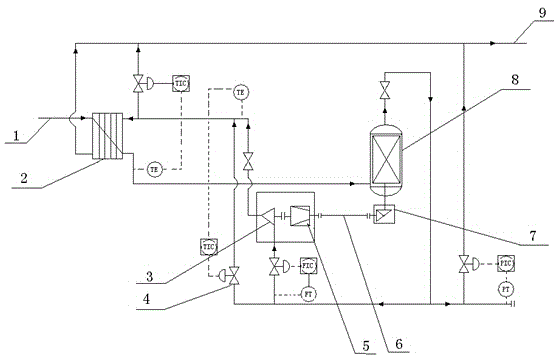

[0018] Such as figure 1 As shown, a device for treating organic solvents in chemical tail gas includes a condenser 2 and a turbo expander 3, and the outlet end of the condenser 2 is connected with a strengthened separator 8, and the strengthened separator 8 includes a shell body, the housing has a built-in high-efficiency separation packing bed, and the drive shaft of the high-efficiency separation packing bed is connected to the output shaft of the second reduction box 7; the input shaft of the second reduction box 7 is connected to the first reduction box 5 through the transmission shaft 6 The output shaft of the first reduction box 5 is connected with the rotor of the turbo expander 3; the gas outlet of the reinforced separator 8 is connected with the intake end of the turbo expander 3, and the turbo expander The gas outlet of 3 is connected with condenser 2.

[0019] Further, the turboexpander 3 and the first reduction box 5 are arranged coaxially, and the second reductio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com