Refrigerator middle beam assembly and refrigerator

A technology of beam components and refrigerators, which is applied in the direction of household refrigerators, coolers, lighting and heating equipment, etc. It can solve the problems of complex assembly process of center beam structure and anti-condensation pipe, and the installation of anti-condensation pipe is not firm, so as to achieve simple assembly convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

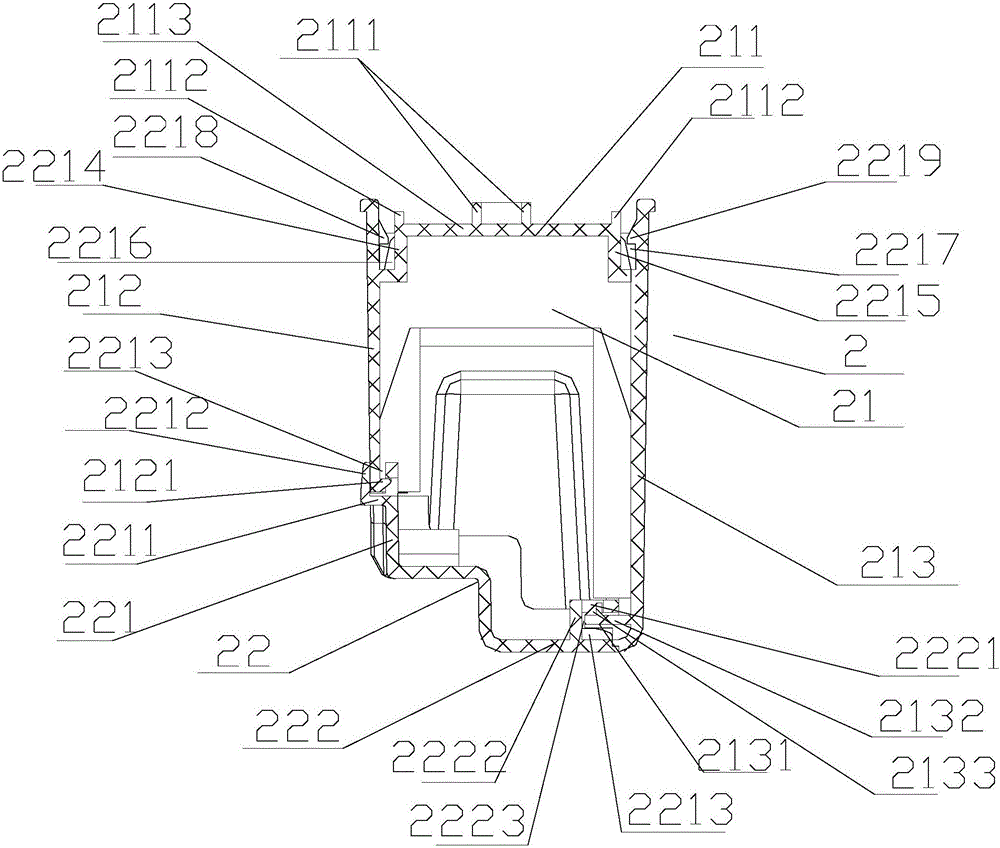

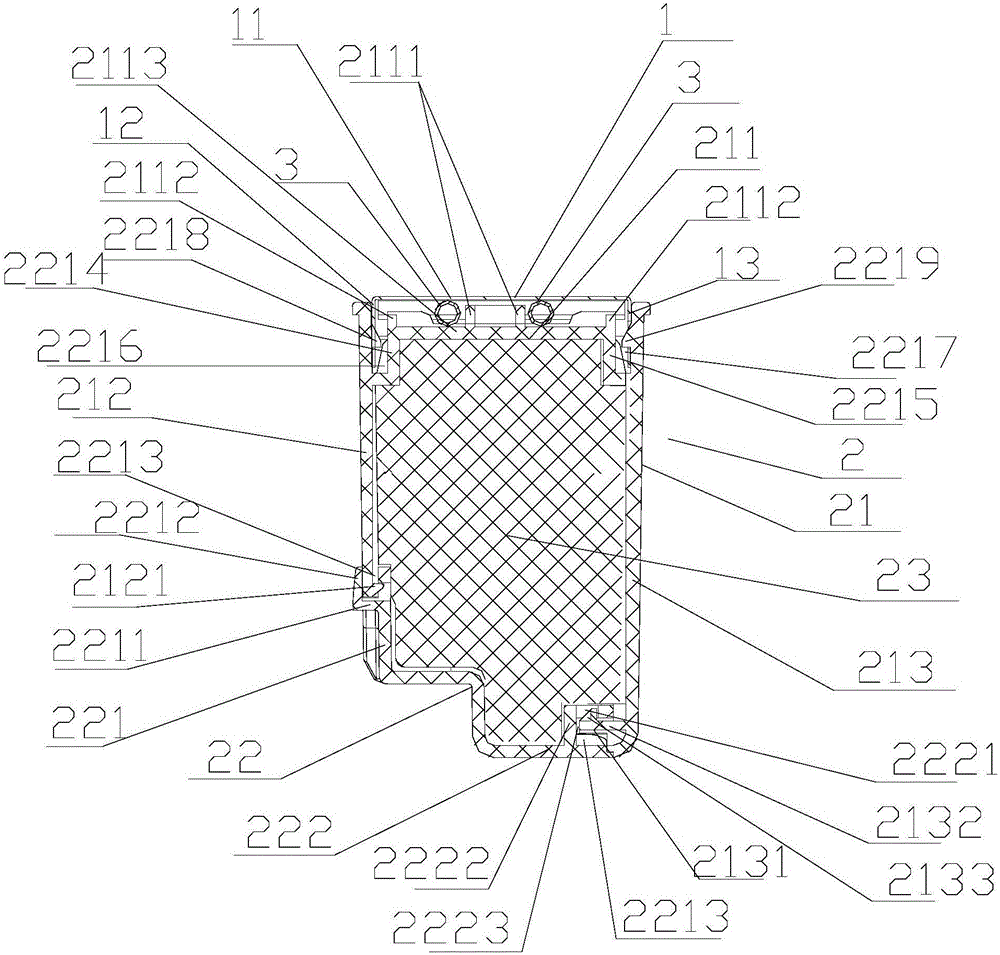

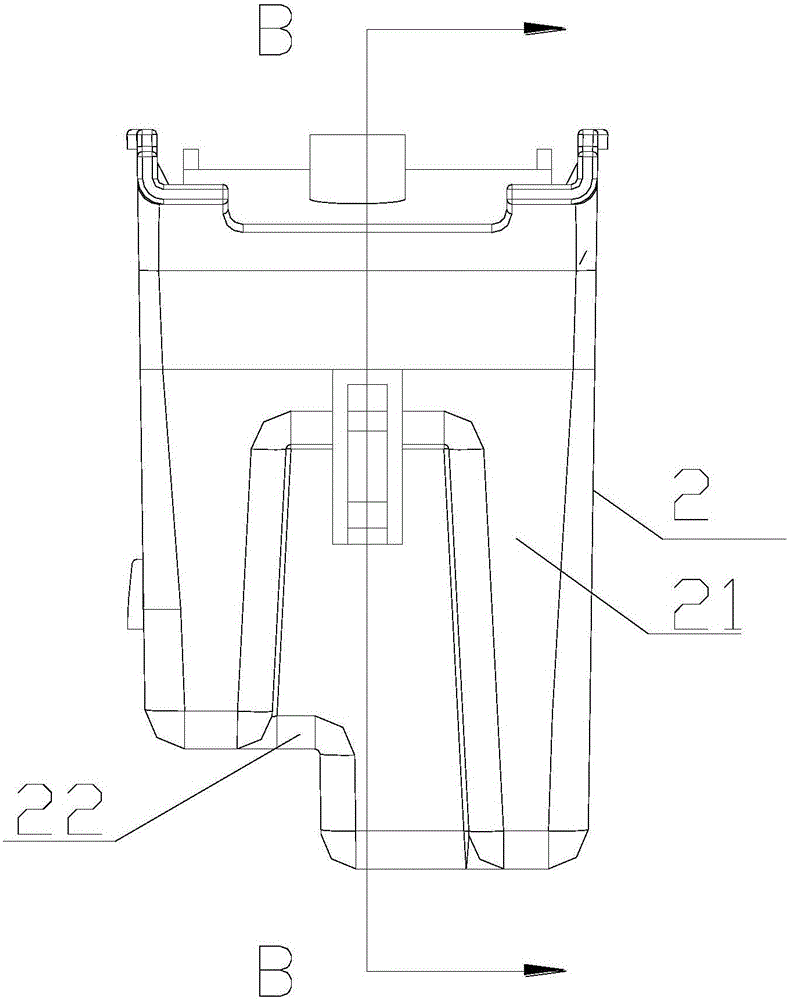

[0057] Such as Figure 1-Figure 8 As shown, a refrigerator center beam assembly of this embodiment is assembled on the inner wall of the refrigerator, including:

[0058] A middle beam 1, the middle beam 1 is fixedly installed on the inner wall of the refrigerator;

[0059] The installation box 2, the top plate of the installation box 2 is an installation plate 211, and the outer surface of the installation plate 211 is detachably connected with the middle beam 1; There are separation ribs 2111 and stop ribs 2112, the separation ribs 2111 are located in the middle of the installation plate 211, the stop ribs 2112 are two parallel arrangements and are respectively located at the ends of the separation ribs 2111 Both sides; the separation ribs 2111 and the stop ribs 2112 are arranged parallel to the center beam 1; the separation ribs are arranged in a ring on the upper surface of the mounting plate, including two sections arranged in parallel and in a straight line The first r...

Embodiment 2

[0094] A refrigerator in this embodiment includes the refrigerator center beam assembly as described in Embodiment 1, and the center beam is fixedly installed on the inner wall of the refrigerator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com